Монтаж гипсокартонных потолков самостоятельно are usually made on a metal frame. Suspended ceilings in apartments can be single-level or multi-level. Built-in lamps are often installed in them. Installing a plasterboard ceiling levels low, uneven ceilings. Plasterboard ceiling evens out lowuneven ceilings, which creates a beautiful and stylish interior in the house. Multi-level ceilings diversify the design of the premises. Their second advantage is the ability to build in ceiling lights with a high base. This technique was used when there was no LED lighting technology and modern lamps. With the advent of new compact lamps, the fashion for installing complex and expensive ones began to gradually disappear.

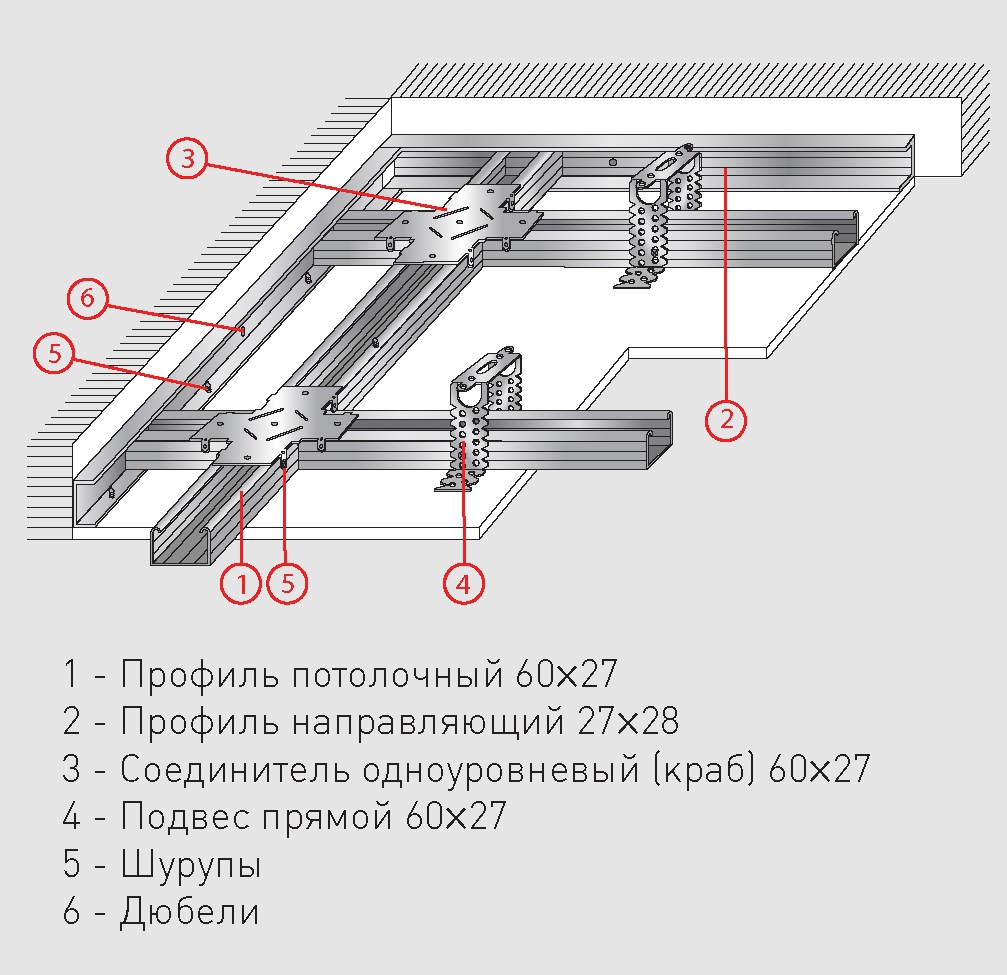

Plasterboard ceiling evens out lowuneven ceilings, which creates a beautiful and stylish interior in the house. Multi-level ceilings diversify the design of the premises. Their second advantage is the ability to build in ceiling lights with a high base. This technique was used when there was no LED lighting technology and modern lamps. With the advent of new compact lamps, the fashion for installing complex and expensive ones began to gradually disappear. Scheme of the plasterboard ceiling frame.There are many people ready to do it. Single-level ceilings made of gypsum board in an apartment are a great solution for those who want to make a quality renovation. The technology of installing a single-level ceiling interests many people, the number of questions is only increasing. At the same time, the number of amateurs who understand the simplest things in their own way is also increasing. Installation of a plasterboard ceiling is carried out using classical technology. There is no need to complicate the installation process if there is a simple solution.

Scheme of the plasterboard ceiling frame.There are many people ready to do it. Single-level ceilings made of gypsum board in an apartment are a great solution for those who want to make a quality renovation. The technology of installing a single-level ceiling interests many people, the number of questions is only increasing. At the same time, the number of amateurs who understand the simplest things in their own way is also increasing. Installation of a plasterboard ceiling is carried out using classical technology. There is no need to complicate the installation process if there is a simple solution.

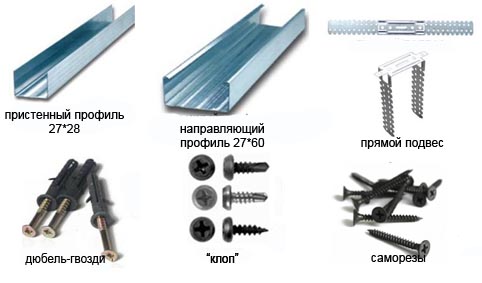

Materials for gipsokartonnogo ceiling

Return to Contents</a>

Tools and accessories

Tools for installing plasterboard ceilings.

Tools for installing plasterboard ceilings.

Return to Contents</a>

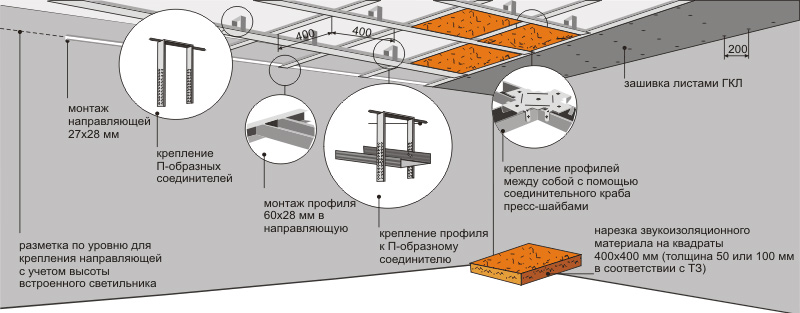

Installing a Guide Profile

Installation of plasterboard ceilings begins withinstallation of the PNP guide profile (28x27), it is sometimes simply called the perimeter. It is usually sold in 3 m lengths. The step of fastening the perimeter to the walls depends on the wall material and the fasteners used. You can use screws or dowel-nails, which are convenient for through fastening. Materials for assembling the ceiling frame fromplasterboard. For concrete walls, 6x40 dowel-nails are used. The advantage of dowel-nails is the high installation speed. For conventional fasteners, the maximum step is approximately 700 mm. For dowel-nails, the fastening step is 350 mm. A solid line of the fastening level is first applied to the walls with a pencil. It is marked using any building level and a ruler. The perimeter is installed exactly above the marking line. Docking elements are not used during the installation of PNP. Gaps at the joints are not allowed. There must be a continuous sealing tape between the wall and the PNP, it is pre-glued to the frame elements. Installation of plasterboard ceilings is carried out after plastering the walls or covering them with gypsum board, this must be done before fixing the perimeter of the plasterboard ceiling. When installing PP profiles, their ends are inserted inside the perimeter. The PP profile is attached to the base ceiling on hangers. A straight, non-adjustable hanger bracket consisting of a backrest and two shelves is usually used. After the backrest is secured at two points, the shelves are bent back. Return to contents</a>

Materials for assembling the ceiling frame fromplasterboard. For concrete walls, 6x40 dowel-nails are used. The advantage of dowel-nails is the high installation speed. For conventional fasteners, the maximum step is approximately 700 mm. For dowel-nails, the fastening step is 350 mm. A solid line of the fastening level is first applied to the walls with a pencil. It is marked using any building level and a ruler. The perimeter is installed exactly above the marking line. Docking elements are not used during the installation of PNP. Gaps at the joints are not allowed. There must be a continuous sealing tape between the wall and the PNP, it is pre-glued to the frame elements. Installation of plasterboard ceilings is carried out after plastering the walls or covering them with gypsum board, this must be done before fixing the perimeter of the plasterboard ceiling. When installing PP profiles, their ends are inserted inside the perimeter. The PP profile is attached to the base ceiling on hangers. A straight, non-adjustable hanger bracket consisting of a backrest and two shelves is usually used. After the backrest is secured at two points, the shelves are bent back. Return to contents</a>

Fastening of suspensions for a skeleton of a ceiling

Plasterboard ceiling marking scheme.At the stage of installing the hangers, the entire frame is marked. First, you need to choose the direction of the ceiling profile. The ceiling looks more beautiful, the fewer joints of the gypsum panels. For these reasons, you should not stick to a single design scheme. There should be less waste of materials, so the required length is selected in the store. The direction of the beams depends on the location of the window. It is recommended to install them in the direction of the light. In the same direction, along the direction of the light, the sheets of drywall are laid with their long side. This is done so that the long joints are less noticeable. You need to approach the task of choosing a design scheme for the frame creatively. It is sometimes impossible to mark the location of the hangers accurately all over the ceiling, especially if the corners of the room are not right angles. In this case, experienced builders recommend cutting the first sheet and trial fixing it, for this you only need to make the necessary markings and fasten the hangers for the first and second profiles. Having made sure that the joint of the first sheet is exactly in the middle of the profile, you can do further marking of the hangers. Some recommend cutting half of the sheet, especially if you have to work alone, without an assistant. In this case, the installation of the plasterboard ceiling begins with an indent of half a sheet. First, a whole sheet is installed, then the gap near the wall is cut and closed.

Plasterboard ceiling marking scheme.At the stage of installing the hangers, the entire frame is marked. First, you need to choose the direction of the ceiling profile. The ceiling looks more beautiful, the fewer joints of the gypsum panels. For these reasons, you should not stick to a single design scheme. There should be less waste of materials, so the required length is selected in the store. The direction of the beams depends on the location of the window. It is recommended to install them in the direction of the light. In the same direction, along the direction of the light, the sheets of drywall are laid with their long side. This is done so that the long joints are less noticeable. You need to approach the task of choosing a design scheme for the frame creatively. It is sometimes impossible to mark the location of the hangers accurately all over the ceiling, especially if the corners of the room are not right angles. In this case, experienced builders recommend cutting the first sheet and trial fixing it, for this you only need to make the necessary markings and fasten the hangers for the first and second profiles. Having made sure that the joint of the first sheet is exactly in the middle of the profile, you can do further marking of the hangers. Some recommend cutting half of the sheet, especially if you have to work alone, without an assistant. In this case, the installation of the plasterboard ceiling begins with an indent of half a sheet. First, a whole sheet is installed, then the gap near the wall is cut and closed. The plasterboard sheets are screwed to themetal frame. Each flat hanger (universal bracket) is attached to the base ceiling at two points through the two extreme holes of the back. The bracket is sold unfolded, the shelves are bent after the hanger is attached to the base ceiling. The excess shelf length is bent at an angle of 90 degrees or cut off in advance so that it does not interfere with attaching the sheets. The central hole is designed for using an additional anchor in cases where it is necessary to lower the ceiling lower. To ensure play in the anchor, the hole is made oval. Using a flat hanger, you can ensure a distance of only 12 cm between the base and suspended ceiling. The hanger allows you to install the PP profile at different heights due to the perforation of the shelves. For apartments with low ceilings, special shortened hangers are available so that they do not need to be bent or cut. The profile can be attached directly to the base ceiling, without hangers. It is necessary to use a gasket for noise protection. If this is not done, then in places of contact with the reinforced concrete floor, metal profiles can produce very unpleasant clicks during temperature changes in length or at the moment of minimal deformations of the structure when the load on the floors changes. If lamps are built into the suspended ceiling, then it is necessary to calculate in advance the required distance between the base and suspended ceiling. The distance between the hangers is taken from design considerations; no calculations for the bearing capacity are required.

The plasterboard sheets are screwed to themetal frame. Each flat hanger (universal bracket) is attached to the base ceiling at two points through the two extreme holes of the back. The bracket is sold unfolded, the shelves are bent after the hanger is attached to the base ceiling. The excess shelf length is bent at an angle of 90 degrees or cut off in advance so that it does not interfere with attaching the sheets. The central hole is designed for using an additional anchor in cases where it is necessary to lower the ceiling lower. To ensure play in the anchor, the hole is made oval. Using a flat hanger, you can ensure a distance of only 12 cm between the base and suspended ceiling. The hanger allows you to install the PP profile at different heights due to the perforation of the shelves. For apartments with low ceilings, special shortened hangers are available so that they do not need to be bent or cut. The profile can be attached directly to the base ceiling, without hangers. It is necessary to use a gasket for noise protection. If this is not done, then in places of contact with the reinforced concrete floor, metal profiles can produce very unpleasant clicks during temperature changes in length or at the moment of minimal deformations of the structure when the load on the floors changes. If lamps are built into the suspended ceiling, then it is necessary to calculate in advance the required distance between the base and suspended ceiling. The distance between the hangers is taken from design considerations; no calculations for the bearing capacity are required. Installation diagram of a plasterboard ceiling.The load-bearing capacity of one suspension is approximately 45 kg, this must be taken into account in the place of fastening the chandelier. For a very heavy chandelier, a special fastening design is developed or the number of frame fastening points is increased so that it can bear the additional load. Regular chandeliers can be suspended from the frame without additional measures. The normal distance between the suspensions should be 700 mm - 1000 mm (up to 1200 mm). Another design requirement is that the suspensions must be staggered on the ceiling. At the ends, the PP is inserted into the PNP profile, this is considered an attachment point. The distance between the attachment point in the perimeter and the attachment point on the suspension is standardized, it should not be more than 800 mm. Considering that the attachment points of the suspensions alternate in a staggered order, their number changes. For example, if the profile length is 3.0 meters, the first suspension is attached in the middle, the next suspension can be at a distance of 1000 mm. There will be a total of 5 attachment points: three suspensions and two fasteners in the perimeter. The following profile is sufficient to be fixed at four points (two hangers and two fasteners at the ends). With a profile length of 2.0 m, there will be either three or four fastening points, respectively. If the ceiling is longer than four meters, then it is allowed to join the profiles. If the beams are joined, then a hanger is needed on each side of the joint. It is necessary to cut the PP parts accurately; cutting in a pack according to one measurement is not allowed. It is impossible to insert the profile with force; a minimum gap between the parts is required, no more than 1.0 mm. To do this, the parts are cut to a length 5-7 mm shorter than the distance between the walls in a particular place. The frame should work silently; this depends on the correct cutting of the parts and assembly, as well as on the presence of flexible sealing gaskets. Return to the table of contents</a>

Installation diagram of a plasterboard ceiling.The load-bearing capacity of one suspension is approximately 45 kg, this must be taken into account in the place of fastening the chandelier. For a very heavy chandelier, a special fastening design is developed or the number of frame fastening points is increased so that it can bear the additional load. Regular chandeliers can be suspended from the frame without additional measures. The normal distance between the suspensions should be 700 mm - 1000 mm (up to 1200 mm). Another design requirement is that the suspensions must be staggered on the ceiling. At the ends, the PP is inserted into the PNP profile, this is considered an attachment point. The distance between the attachment point in the perimeter and the attachment point on the suspension is standardized, it should not be more than 800 mm. Considering that the attachment points of the suspensions alternate in a staggered order, their number changes. For example, if the profile length is 3.0 meters, the first suspension is attached in the middle, the next suspension can be at a distance of 1000 mm. There will be a total of 5 attachment points: three suspensions and two fasteners in the perimeter. The following profile is sufficient to be fixed at four points (two hangers and two fasteners at the ends). With a profile length of 2.0 m, there will be either three or four fastening points, respectively. If the ceiling is longer than four meters, then it is allowed to join the profiles. If the beams are joined, then a hanger is needed on each side of the joint. It is necessary to cut the PP parts accurately; cutting in a pack according to one measurement is not allowed. It is impossible to insert the profile with force; a minimum gap between the parts is required, no more than 1.0 mm. To do this, the parts are cut to a length 5-7 mm shorter than the distance between the walls in a particular place. The frame should work silently; this depends on the correct cutting of the parts and assembly, as well as on the presence of flexible sealing gaskets. Return to the table of contents</a>

Ceiling profile fixing

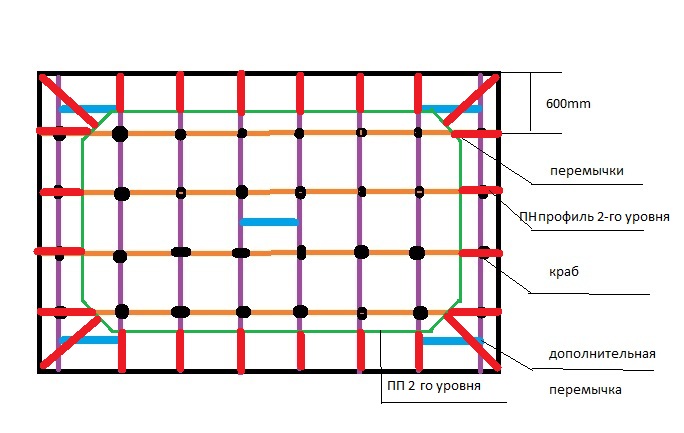

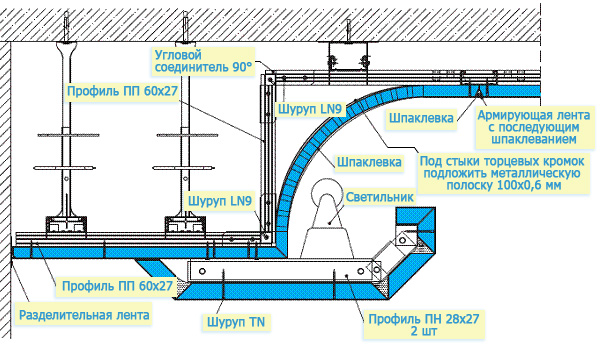

Installation diagram of a two-level ceiling made ofplasterboard. Ceiling structures must be installed strictly horizontally. To ensure their uniform level, threads are pulled in several places in the room. The profile is located between the shelves of the suspension and is attached on both sides. It is more convenient to work with an assistant, since it is necessary to hold the parts and check the level. Fastening is carried out through perforation on the hangers. The frame consists of not only longitudinal elements. Jumpers are needed for the rigidity of the ceiling and for joining sheets in the transverse direction. They are attached between the longitudinal profiles using special connecting parts. It is permissible not to use special parts; for this, a piece of PP of a homemade design is made. With metal scissors, cuts are made at the ends so that the profile can be joined. Return to the table of contents</a>

Installation diagram of a two-level ceiling made ofplasterboard. Ceiling structures must be installed strictly horizontally. To ensure their uniform level, threads are pulled in several places in the room. The profile is located between the shelves of the suspension and is attached on both sides. It is more convenient to work with an assistant, since it is necessary to hold the parts and check the level. Fastening is carried out through perforation on the hangers. The frame consists of not only longitudinal elements. Jumpers are needed for the rigidity of the ceiling and for joining sheets in the transverse direction. They are attached between the longitudinal profiles using special connecting parts. It is permissible not to use special parts; for this, a piece of PP of a homemade design is made. With metal scissors, cuts are made at the ends so that the profile can be joined. Return to the table of contents</a>

Fastening of plasterboard sheets

For ceilings, plasterboard of thickness is usedfrom 8 to 9.5 mm. For rooms with normal air humidity, choose gray sheets. The standard sheet width is 120 mm. The minimum sheet length is 2500 mm, the maximum is 3000 mm. Plasterboard sheets are installed starting from the wall. Installation of a plasterboard ceiling starts from the far corner opposite the wall with a window. They must be precisely joined in the middle of the profile without a gap. A gap of about 2.5 mm is needed only for cut joints so that the putty holds better. Special self-tapping screws are used for fastening. The sheets are mounted staggered so that the joints do not join in one line. It is better to stagger half the length of the sheet for ease of marking the ceiling. Drywall is cut with a knife and an aluminum ruler. The sheets are fastened along the perimeter and in the middle of the sheet, the fastening step is minimal - 200 mm, maximum - 350 mm. Normal step - 300 mm. Installation of plasterboard ceilings is allowed in damp rooms and in rooms with increased fire safety standards.