Carrying out construction work that requiresinsulating walls with plasterboard is one of the quick and relatively inexpensive methods that allows you to prevent heat loss in the house. How to insulate a wall? Scheme of finishing walls with plasterboard.The work is carried out independently, without the involvement of professional builders. It is necessary to purchase the necessary tools. The question involuntarily arises: what does this have to do with gypsum plasterboards, which are not an insulator and heat insulator? During the installation of the boards, a gap appears between the wall and the plaster, the presence of air no longer allows the temperature to drop in the heated room. The gypsum plasterboard boards have a smooth surface. This makes it possible to carry out insulation work with other insulating materials between the wall and the gypsum plasterboard boards. Insulation is carried out in two ways:

Scheme of finishing walls with plasterboard.The work is carried out independently, without the involvement of professional builders. It is necessary to purchase the necessary tools. The question involuntarily arises: what does this have to do with gypsum plasterboards, which are not an insulator and heat insulator? During the installation of the boards, a gap appears between the wall and the plaster, the presence of air no longer allows the temperature to drop in the heated room. The gypsum plasterboard boards have a smooth surface. This makes it possible to carry out insulation work with other insulating materials between the wall and the gypsum plasterboard boards. Insulation is carried out in two ways:

- frame (gypsum boards are mounted on a lath made of metal profiles or wooden slats);

- frameless (gypsum cardboard is fixed to a heatable surface with the help of special mixtures).

Tools needed to work withplasterboard. Reducing heat loss using the above methods when finishing a room leads to a reduction in the size of the living space. Carrying out insulation work using plasterboard is a method that helps eliminate drafts. Using insulation, you eliminate the need to spend money on purchasing additional equipment for heating the room. List of tools required for carrying out work on:

Tools needed to work withplasterboard. Reducing heat loss using the above methods when finishing a room leads to a reduction in the size of the living space. Carrying out insulation work using plasterboard is a method that helps eliminate drafts. Using insulation, you eliminate the need to spend money on purchasing additional equipment for heating the room. List of tools required for carrying out work on:

Frameless thermal insulation method

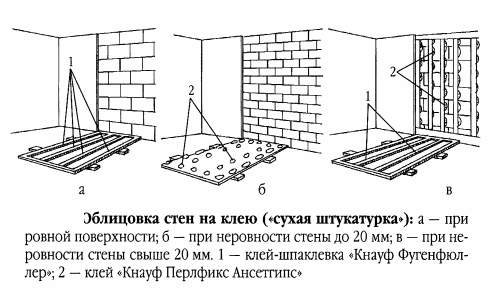

Using the above method, the slabs areplasterboard, install walls made of concrete, brickwork, foam blocks, clay blocks. Make sure that the gap is minimal, as this will be useful in the future. Before installation using plasterboard, it is necessary to carry out work related to cleaning the insulated surface from wallpaper residues, dirt, dust. Scheme of fastening plasterboard with glue.Work is carried out to eliminate cracks in the walls in order to prevent the appearance of "cold corridors". After this, the walls are treated with an antifungal agent, which is purchased in specialized construction stores. Now you can proceed to fixing the gypsum panels. For this, you need the KNAUF-Perlfix gypsum mounting adhesive, the KNAUF-Fugen GV gypsum putty or the VOLMA-Montazh gypsum adhesive. The gypsum boards are strengthened taking into account that they are at a distance of approximately 15 mm from the floor and ceiling. Gluing is carried out using a notched trowel by applying gypsum adhesive to the surface of the gypsum board, evenly distributing the adhesive mixture over the entire plane of the gypsum. After this, the gypsum is placed against the insulated surface and the board is installed in the desired place using uniform dynamic pressure. The same process is done with the next board. Subsequently, attention is paid to the fact that the seams between the slabs are as small as possible. If the insulated surface has critical irregularities, the plasterboard slabs are glued to the "beacons" installed in advance on the wall, set according to the level. Return to the table of contents</a>

Scheme of fastening plasterboard with glue.Work is carried out to eliminate cracks in the walls in order to prevent the appearance of "cold corridors". After this, the walls are treated with an antifungal agent, which is purchased in specialized construction stores. Now you can proceed to fixing the gypsum panels. For this, you need the KNAUF-Perlfix gypsum mounting adhesive, the KNAUF-Fugen GV gypsum putty or the VOLMA-Montazh gypsum adhesive. The gypsum boards are strengthened taking into account that they are at a distance of approximately 15 mm from the floor and ceiling. Gluing is carried out using a notched trowel by applying gypsum adhesive to the surface of the gypsum board, evenly distributing the adhesive mixture over the entire plane of the gypsum. After this, the gypsum is placed against the insulated surface and the board is installed in the desired place using uniform dynamic pressure. The same process is done with the next board. Subsequently, attention is paid to the fact that the seams between the slabs are as small as possible. If the insulated surface has critical irregularities, the plasterboard slabs are glued to the "beacons" installed in advance on the wall, set according to the level. Return to the table of contents</a>

Installation of gypsum boards on a wooden frame

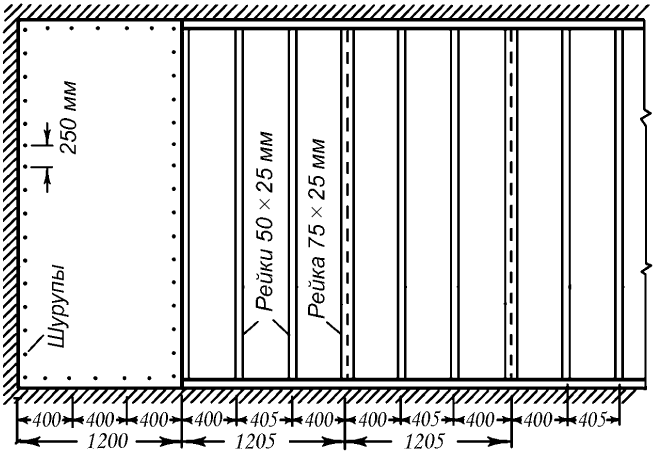

This method is used whenthe walls have strong curvatures, and the ceiling is very high. A lattice of 40 mm thick wooden slats is installed on the wall using horizontal and vertical guides with dowels. The gypsum boards for insulation should lie on three vertical guides so that the front side is completely covered. A regular gypsum board is 2500x1200 mm in size, so under each board there should be three vertical slats and two horizontal ones (for reinforcement near the ceiling and floor). Installation is carried out with wood screws at intervals of 50 mm along the entire length of the guide slats. Return to contents</a>

Warming walls with plasterboard on a metal frame

Scheme of fastening of metal frame underDrywall. Using metal profiles when installing drywall allows for multi-level installation of the boards. Using a water level, mark the frame attachment point. Then install the guide profiles, secure them with dowels and install the vertical profiles using a screwdriver and a press washer with a drill. Check the vertical and horizontal levels after each installation using a pre-stretched thread and a regular 1 m level. After installing the frame, place the insulating material (mineral wool) in the middle of the lathing, then cover the entire surface of the frame with a vapor barrier sheet. Only then proceed to installing the drywall. Thus, the walls are insulated from the inside. Strengthening is carried out with gypsum screws, starting from the upper right corner in a perpendicular direction with an indent of 5-10 mm, at a frequency of at least 300 mm. When carrying out work related to insulation with gypsum boards in two layers, the installation is done with a 50% shift of the boards towards the next board. They are fastened with longer screws with a recessed head. All installation sites are subsequently puttied. The joints of the boards are treated with finishing putty using a special mesh for reinforcement. The dried surface is sanded until a flat plane is obtained for further decoration of the walls. You will make your home warmer.

Scheme of fastening of metal frame underDrywall. Using metal profiles when installing drywall allows for multi-level installation of the boards. Using a water level, mark the frame attachment point. Then install the guide profiles, secure them with dowels and install the vertical profiles using a screwdriver and a press washer with a drill. Check the vertical and horizontal levels after each installation using a pre-stretched thread and a regular 1 m level. After installing the frame, place the insulating material (mineral wool) in the middle of the lathing, then cover the entire surface of the frame with a vapor barrier sheet. Only then proceed to installing the drywall. Thus, the walls are insulated from the inside. Strengthening is carried out with gypsum screws, starting from the upper right corner in a perpendicular direction with an indent of 5-10 mm, at a frequency of at least 300 mm. When carrying out work related to insulation with gypsum boards in two layers, the installation is done with a 50% shift of the boards towards the next board. They are fastened with longer screws with a recessed head. All installation sites are subsequently puttied. The joints of the boards are treated with finishing putty using a special mesh for reinforcement. The dried surface is sanded until a flat plane is obtained for further decoration of the walls. You will make your home warmer.