The abundance of building materials allowsto erect a building using several types of them. For example, the outer part of the building can be constructed from brick or cinder block, and the internal partitions can be made of foam concrete or aerated concrete. Using these blocks for piers will save on building a house and improve the thermal insulation of the premises. The interior decoration of walls made of aerated concrete has several features that you need to know before starting work. Scheme of a house wall made of aerated concrete.

Scheme of a house wall made of aerated concrete.

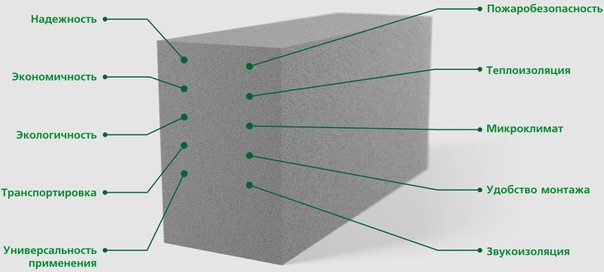

Features of aerocrete blocks

The production of aerated concrete is a complex processtechnological process. As a result of mixing cement, lime, quartz sand, the basis for obtaining this building material is formed. After adding aluminum chips, bubbles begin to form in the concrete. After pouring into molds and hardening of the resulting mixture, aerated concrete blocks are ready for use. The advantages of aerated concrete blocks include the following properties:

- good thermal insulation;

- fire resistance;

- excellent sound insulation;

- frost resistance;

- the ability to maintain indoor microclimate;

- duration of operation;

- simplicity in processing and weight;

- no possibility of penetration of fungi and mold into the material.

These advantages allow the use of aerated concrete blocks for the construction of internal and external walls of buildings of any purpose in various climatic conditions. Return to contents</a>

The main nuances of the walls

Features of aerated concrete block. When choosing finishing materials for walls made of aerated concrete, it is necessary to take into account several points that exclude each other:

Features of aerated concrete block. When choosing finishing materials for walls made of aerated concrete, it is necessary to take into account several points that exclude each other:

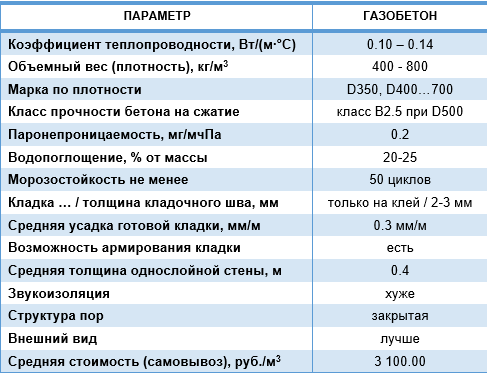

The choice you make will determineclimatic characteristics of the room, durability and strength of aerated concrete walls. A finishing material that has good vapor permeability properties is gypsum plaster. It will allow the walls of aerated concrete blocks to retain their technical characteristics. Such plaster is sold as a dry mix, which must be prepared in accordance with the instructions on the package. In addition to gypsum, the composition includes perlite sand, slaked lime. This combination of components allows you to increase sound insulation, improves fire protection of the room. In addition, the plaster is applied to aerated concrete walls not treated with a special primer solution, it is easy to process. Final alignment can be done without the use of putty. Vapor impermeability of aerated concrete blocks will increase the pasting of vinyl wallpaper. Such finishing material reduces this figure by 10 times. Fixing polyethylene or special film on a wall made of aerated concrete blocks also helps to reduce vapor permeability properties. However, the use of such films can cause condensation, which can destroy aerated concrete blocks. Characteristics of aerated concrete.As an interior finish, a regular plaster solution is most often used. It includes cement, sand (it is possible to use various additives). But plastered aerated concrete walls can become damp during operation, which causes peeling of the finishing material. Therefore, in order to achieve good vapor impermeability in practice, a combination of building materials is used. It looks like this: 1 layer of primer is applied to the surface, after it dries, another 2-3 layers, each of which must be absorbed. Then the wall of aerated concrete blocks is plastered with a gypsum mixture. After this, the final finishing of the premises is carried out. The choice of material for these purposes is also important. For example, if the surface of the walls is painted with oil paint, then the vapor permeability will decrease. Water-emulsion paints do not give such an effect, and the rate of vapor penetration into aerated concrete does not change. Return to contents</a>

Characteristics of aerated concrete.As an interior finish, a regular plaster solution is most often used. It includes cement, sand (it is possible to use various additives). But plastered aerated concrete walls can become damp during operation, which causes peeling of the finishing material. Therefore, in order to achieve good vapor impermeability in practice, a combination of building materials is used. It looks like this: 1 layer of primer is applied to the surface, after it dries, another 2-3 layers, each of which must be absorbed. Then the wall of aerated concrete blocks is plastered with a gypsum mixture. After this, the final finishing of the premises is carried out. The choice of material for these purposes is also important. For example, if the surface of the walls is painted with oil paint, then the vapor permeability will decrease. Water-emulsion paints do not give such an effect, and the rate of vapor penetration into aerated concrete does not change. Return to contents</a>

Required Tools

To carry out the construction process, the following devices are required:

- perforator;

- a hammer;

- level;

- roulette;

- Bulgarian;

- Screwdriver;

- plumb bob;

- lacing;

- scissors for metal.

Return to Contents</a>

Types of finishes: some features

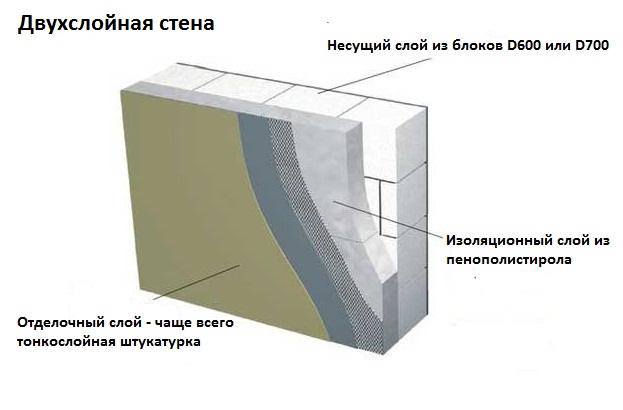

Scheme of finishing an aerated concrete wall with plaster.Depending on the method of application or fastening, the finishing is done with or without a frame. If you choose the frame method, then the finishing of walls made of aerated concrete blocks can be done with plasterboard sheets, OSB boards, decorative panels. Before framing, waterproofing and vapor barrier films are successively fixed to the aerated concrete walls. They will protect the wall material from moisture penetration and increase its service life. First, the frame is built. If plasterboard is adopted as the cladding material, then aluminum profiles are used for the frame. They are fastened with dowels to aerated concrete blocks. It is necessary to strictly monitor the observance of the vertical and horizontal, using a building level. After completing the lathing, screw the plasterboard sheets onto self-tapping screws. The plasterboard caps should be deepened a little. After the plasterboard is fixed, puttying work is carried out. If the finishing is done with decorative panels, then the frame is made of bars with a cross-section of 25x25 mm. The wooden lathing is done on dowels, drilling holes or self-tapping screws. The first bar is fixed to the ceiling, the second to the floor. Between them, after pulling the thread, the remaining bars of the lathing are mounted at a distance of 50-60 cm, depending on the size of the panels. Compliance with the horizontal is controlled by the level. This is necessary in order to prevent distortions of the decorative panels. A special profile is fixed at the corner, into the groove of which the panels will be inserted. Then, with self-tapping screws, nails, staples, all the decorative elements of the wall are fixed in turn. But the last panel is not rigidly attached to the frame, but is inserted into the same corner groove of the profile as at the beginning. If it is decided to use frameless finishing, for example, painting, wallpapering, then the following steps must be taken:

Scheme of finishing an aerated concrete wall with plaster.Depending on the method of application or fastening, the finishing is done with or without a frame. If you choose the frame method, then the finishing of walls made of aerated concrete blocks can be done with plasterboard sheets, OSB boards, decorative panels. Before framing, waterproofing and vapor barrier films are successively fixed to the aerated concrete walls. They will protect the wall material from moisture penetration and increase its service life. First, the frame is built. If plasterboard is adopted as the cladding material, then aluminum profiles are used for the frame. They are fastened with dowels to aerated concrete blocks. It is necessary to strictly monitor the observance of the vertical and horizontal, using a building level. After completing the lathing, screw the plasterboard sheets onto self-tapping screws. The plasterboard caps should be deepened a little. After the plasterboard is fixed, puttying work is carried out. If the finishing is done with decorative panels, then the frame is made of bars with a cross-section of 25x25 mm. The wooden lathing is done on dowels, drilling holes or self-tapping screws. The first bar is fixed to the ceiling, the second to the floor. Between them, after pulling the thread, the remaining bars of the lathing are mounted at a distance of 50-60 cm, depending on the size of the panels. Compliance with the horizontal is controlled by the level. This is necessary in order to prevent distortions of the decorative panels. A special profile is fixed at the corner, into the groove of which the panels will be inserted. Then, with self-tapping screws, nails, staples, all the decorative elements of the wall are fixed in turn. But the last panel is not rigidly attached to the frame, but is inserted into the same corner groove of the profile as at the beginning. If it is decided to use frameless finishing, for example, painting, wallpapering, then the following steps must be taken:

- hardening and rough alignment;

- grinding.

Return to Contents</a>

Practical recommendations for wall decoration

Tools for applying plaster.Plaster is used for rough leveling. To strengthen the wall, you can use a fine-mesh mesh, which is fixed with mortar. The plaster is purchased ready-made. The packaged dry mixture is diluted with water in the proportion indicated on the package. If you prepare the solution yourself, then take cement, fine sand (or sifted lime mortar) in a ratio of 1:3 and add water until a thin mass is obtained. After the starting coat has hardened, it is processed with coarse sandpaper, smoothing out large drips. Next, apply the finishing coat, which is finer, which allows it to fill in all the irregularities. When the surface has dried, it is finally sanded. Before gluing the wallpaper, the walls should be covered with a layer of primer. This will facilitate gluing. Only after completing this work is it possible to cover with wallpaper (or paint). Paint of any composition and base is suitable for painting. The use of water-based paint is most common. This is due to the ease of application and the ability to create shades yourself. To do this, just mix a white helmet with a color pigment in the right proportion. It should be borne in mind that in this case there should be enough paint for the entire surface, since it will be difficult to repeat the shade exactly. The paint is applied in several layers with a roller or brush, without waiting for each layer to dry. Due to the fact that the paint is quite liquid, it is permissible to use a sprayer. Even layers are inflated horizontally, odd ones - vertically. This method allows you to avoid gaps. Thus, an even layer is formed. Wallpaper of various designs can be used. Paper, vinyl, washable are quite suitable. Wallpaper is glued according to the technological features of the material from which it is made. Ceramic tiles are also suitable as a facing material for aerated concrete walls. It is fixed with an adhesive composition, which is sold ready for use. If aerated concrete blocks are used as the main building material for the entire house, then the exterior finishing is carried out taking into account all its features.

Tools for applying plaster.Plaster is used for rough leveling. To strengthen the wall, you can use a fine-mesh mesh, which is fixed with mortar. The plaster is purchased ready-made. The packaged dry mixture is diluted with water in the proportion indicated on the package. If you prepare the solution yourself, then take cement, fine sand (or sifted lime mortar) in a ratio of 1:3 and add water until a thin mass is obtained. After the starting coat has hardened, it is processed with coarse sandpaper, smoothing out large drips. Next, apply the finishing coat, which is finer, which allows it to fill in all the irregularities. When the surface has dried, it is finally sanded. Before gluing the wallpaper, the walls should be covered with a layer of primer. This will facilitate gluing. Only after completing this work is it possible to cover with wallpaper (or paint). Paint of any composition and base is suitable for painting. The use of water-based paint is most common. This is due to the ease of application and the ability to create shades yourself. To do this, just mix a white helmet with a color pigment in the right proportion. It should be borne in mind that in this case there should be enough paint for the entire surface, since it will be difficult to repeat the shade exactly. The paint is applied in several layers with a roller or brush, without waiting for each layer to dry. Due to the fact that the paint is quite liquid, it is permissible to use a sprayer. Even layers are inflated horizontally, odd ones - vertically. This method allows you to avoid gaps. Thus, an even layer is formed. Wallpaper of various designs can be used. Paper, vinyl, washable are quite suitable. Wallpaper is glued according to the technological features of the material from which it is made. Ceramic tiles are also suitable as a facing material for aerated concrete walls. It is fixed with an adhesive composition, which is sold ready for use. If aerated concrete blocks are used as the main building material for the entire house, then the exterior finishing is carried out taking into account all its features.