Plasterboard niches have been a popular choice for many yearsquite an effective method of zoning space. They are used as built-in cabinets, shelves, for dividing a large area, for loggias and balconies. The cost of a plasterboard niche is low, its design itself is simple, even a beginner can handle the work. Before manufacturing, you first need to decide what shape and size it will have. You should first draw up a drawing taking into account the features of the room, its size, parameters and type of niches. Plasterboard niches can be used forstorage of various items or for zoning the room. The plasterboard structure can take various variations, most often it is built during the general renovation of the room. You can make such niches when the general furnishings are already ready. For the construction, special galvanized metal profiles or wooden slats are used, they are fastened with self-tapping screws. As a finish, you can use a variety of materials, taking into account the style of the finished interior. For example, for an elegant small niche intended for books and trinkets, beautiful ceramic tiles are perfect, and for a large niche, it is recommended to use decorative plaster or stylish bright wallpaper. The niche can also be decorated with lighting, LED strips, small lamps or miniature table lamps are used for decoration. Everything depends on what the general style of the design will be, what material the shelves are made of.

Plasterboard niches can be used forstorage of various items or for zoning the room. The plasterboard structure can take various variations, most often it is built during the general renovation of the room. You can make such niches when the general furnishings are already ready. For the construction, special galvanized metal profiles or wooden slats are used, they are fastened with self-tapping screws. As a finish, you can use a variety of materials, taking into account the style of the finished interior. For example, for an elegant small niche intended for books and trinkets, beautiful ceramic tiles are perfect, and for a large niche, it is recommended to use decorative plaster or stylish bright wallpaper. The niche can also be decorated with lighting, LED strips, small lamps or miniature table lamps are used for decoration. Everything depends on what the general style of the design will be, what material the shelves are made of.

How to make a niche yourself

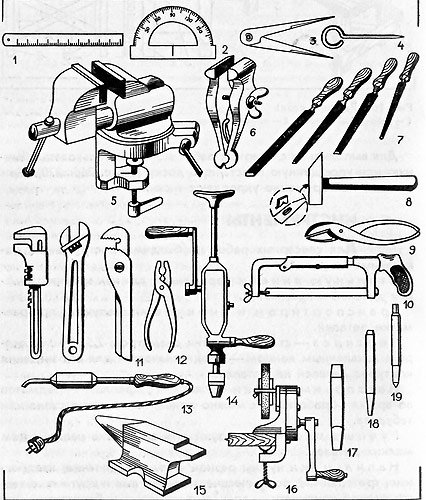

Making a plasterboard niche is a relatively simple job, there is no need to use complex technologies or expensive tools. For work you should prepare: A set of tools for working with plasterboard.

A set of tools for working with plasterboard.

- GCR;

- metallic profile;

- self-tapping screws, dowels;

- Screwdriver;

- a drill with a nozzle;

- building level;

- metal ruler;

- plumb bob;

- pencil;

- putty;

- putty knife;

- finishing materials (the simplest option is paint).

Preparatory work for installing a niche fromPlasterboard includes drafting a project and preparing materials. You can take a ready-made project, selecting your own dimensions for plasterboard niches. It is necessary to take into account the features and dimensions of a particular room. The drawing indicates the parameters for the niche, its depth, appearance. All dimensions are indicated, including the step of the shelves and the material that will be used for their construction. It is important to immediately determine whether there is a need to use lighting, outlets, connection points for a TV, computer. The finishing material should be in perfect harmony with the rest of the furnishings in the room. Even if contrasting colors are used, they should be combined and not become an alien spot. Return to contents</a>

Mounting the frame

Scheme of installation of the frame for plasterboard.Plasterboard niches are mounted on a special frame made of aluminum profile. First, the starting profiles are placed on the floor, walls and ceiling in full accordance with the drawn up drawing. The markings are applied to the surface in advance; they should be as accurate as possible. For convenience, a building level and a special plumb line are used. To fasten the starting profile, you need to take impact dowels of 6x40 mm, they are installed in increments of 40 cm. Then, the vertical profile, the so-called guides, is fastened in increments of approximately 60 cm. A horizontal profile is used for shelves; it is placed at a distance that will correspond to the distance between the shelves. The fastening step depends on what kind of load is required for the shelves. In addition to self-tapping screws for corners, special additional elements may be required; they are purchased together with the profiles. Embedded parts are used only if it is necessary to install heavy household appliances. If lighting is to be used in the niche, switches and sockets are to be mounted, then it is necessary to immediately run cables and install the necessary fittings, since after covering with plasterboard it will no longer be possible to do this work. Return to contents</a>

Scheme of installation of the frame for plasterboard.Plasterboard niches are mounted on a special frame made of aluminum profile. First, the starting profiles are placed on the floor, walls and ceiling in full accordance with the drawn up drawing. The markings are applied to the surface in advance; they should be as accurate as possible. For convenience, a building level and a special plumb line are used. To fasten the starting profile, you need to take impact dowels of 6x40 mm, they are installed in increments of 40 cm. Then, the vertical profile, the so-called guides, is fastened in increments of approximately 60 cm. A horizontal profile is used for shelves; it is placed at a distance that will correspond to the distance between the shelves. The fastening step depends on what kind of load is required for the shelves. In addition to self-tapping screws for corners, special additional elements may be required; they are purchased together with the profiles. Embedded parts are used only if it is necessary to install heavy household appliances. If lighting is to be used in the niche, switches and sockets are to be mounted, then it is necessary to immediately run cables and install the necessary fittings, since after covering with plasterboard it will no longer be possible to do this work. Return to contents</a>

Sheet fastening

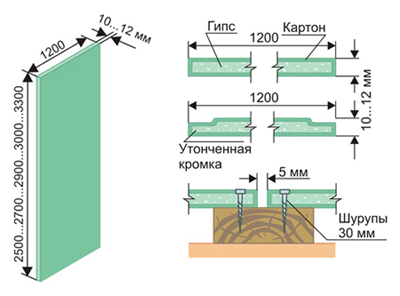

To attach drywall with your own hands, you need to prepare: Scheme of fastening plasterboard sheet to the frame.

Scheme of fastening plasterboard sheet to the frame.

- GKL (excellent common wall plasterboard);

- self-tapping screws for working with plasterboard - 3.5x35 mm, 3.5x25 mm;

- hacksaw;

- metal ruler;

- a simple pencil;

- sandpaper.

The plasterboard must be secured with self-tapping screws.You can also use a screwdriver, but the amount of work is too big, it will be difficult to cope with one screwdriver. Before you start working on the sheathing, the sheets need to be cut. For this, use a metal ruler and a simple pencil, the cutting must be done carefully, according to a previously drawn up scheme. The plasterboard is cut with a knife, first the sheet is cut and carefully broken along the prepared line. When all the elements are ready, you need to start fastening them. First, the distant and complex elements of the plasterboard niche are fixed with self-tapping screws, then the remaining elements are mounted. The heads of the screws are sunk into the material by about 2 mm, they should not protrude above the surface. The step can be 10-15 cm, depending on the size of the individual elements of the niche. Return to the table of contents</a>

Finishing work

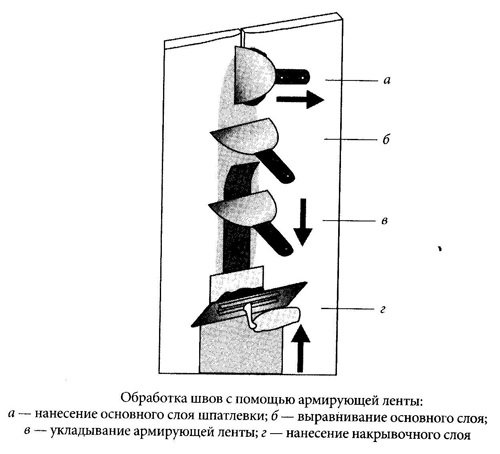

Scheme of sealing plasterboard seams.The final finishing of a plasterboard niche begins with surface preparation. First, it is necessary to remove the area, dust, and leave only those tools and materials that will be needed for further work. Preparation for finishing begins with the design of seams and fastening points. For this, putty and a special mesh are used, as a result, the joints are strong. The putty mixture is diluted in a special container, it is mixed using a drill and a special nozzle. It is necessary for the mass to become homogeneous, only in this case it will be possible to ensure high quality work. Putty is applied only to the joints and fastening points. The second stage of preparation is priming the surface. Special primers for gypsum boards are used, the composition is applied with a roller in one layer. It is needed to protect the surface of the plasterboard niche from mold and mildew. The composition strengthens the surface of the sheathing, increases its service life. Finishing is carried out from various materials, the simplest option is painting. You need to prepare in advance:

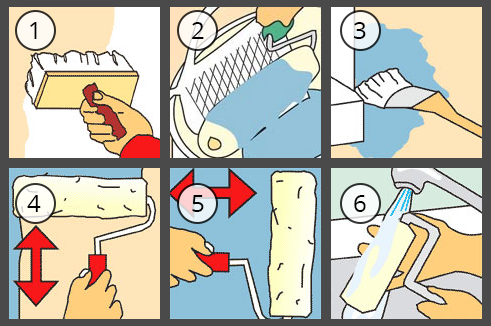

Scheme of sealing plasterboard seams.The final finishing of a plasterboard niche begins with surface preparation. First, it is necessary to remove the area, dust, and leave only those tools and materials that will be needed for further work. Preparation for finishing begins with the design of seams and fastening points. For this, putty and a special mesh are used, as a result, the joints are strong. The putty mixture is diluted in a special container, it is mixed using a drill and a special nozzle. It is necessary for the mass to become homogeneous, only in this case it will be possible to ensure high quality work. Putty is applied only to the joints and fastening points. The second stage of preparation is priming the surface. Special primers for gypsum boards are used, the composition is applied with a roller in one layer. It is needed to protect the surface of the plasterboard niche from mold and mildew. The composition strengthens the surface of the sheathing, increases its service life. Finishing is carried out from various materials, the simplest option is painting. You need to prepare in advance: Painting drywall:1 - priming the surface; 2 - preparing the paint for work; 3 - painting the corners; 4, 5 - the first vertical and second horizontal layers of paint; 6 - cleaning the working tool from paint.

Painting drywall:1 - priming the surface; 2 - preparing the paint for work; 3 - painting the corners; 4, 5 - the first vertical and second horizontal layers of paint; 6 - cleaning the working tool from paint.

- paint the chosen color, you can use beautiful textured paints that will create an unusual but stylish surface;

- roller for the application of conventional and angular paint for the treatment of hard-to-reach surfaces;

- a thin brush, which will be treated surfaces, where the use of the roller is impossible;

- painting tape;

- solvent;

- a bath for paint;

- a container for paint, if it needs to be diluted.

All surfaces that will not be coatedpaint, should be sealed with masking tape. A small amount of paint is poured into the tray, after which the surface is painted. It is recommended to start with hard-to-reach places, internal corners, and paint large spaces with a roller last. Usually 1-2 layers of paint are enough, each of which must dry. In addition to painting, other finishing options are also used for a plasterboard niche. This can be beautiful wallpaper in bright or pastel shades, decorative plaster, ceramic tiles or wood panels. Plasterboard niches are used to zone the space or organize a convenient and attractive place for books, household appliances, toys, etc. With the help of such a niche, you can, without cluttering the space of a small room, transform the interior, make it more attractive. You can arrange a niche with your own hands, you do not need special experience or expensive material.</ ul>