Drywall as a building material is activelyis used to level any surfaces. It allows for installation in a short time and guarantees an excellent result of the work performed. Do-it-yourself plasterboard wall paneling allows you to acquire new skills in interacting with this practical and easy-to-use material. Such boards perfectly hide communications, help to insulate the room and carry out soundproofing. Scheme of wall covering with plasterboard. In order for the installation work to go smoothly and in an organized manner, you should prepare a set of such devices:

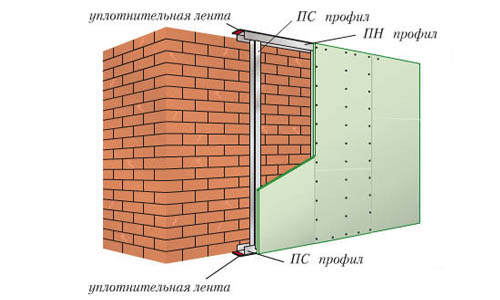

Scheme of wall covering with plasterboard. In order for the installation work to go smoothly and in an organized manner, you should prepare a set of such devices:

- guides;

- dowels;

- drywall;

- gas pistol;

- Bulgarian;

- stairs.

Mounting the frame: recommendations

Do-it-yourself plasterboard wall coveringis associated with the use of two types of profiles: UD and CD. The first type of guides are designed to give the surface perfectly flat indicators. The other type of profiles are designed to strengthen the entire structure and give them volumetric forms. Accordingly, UD guides are mounted on the ceiling, floor, walls. The order of their installation comes down to the following stages: Tools for finishing walls with plasterboard.

Tools for finishing walls with plasterboard.

Further technology of wall cladding as specifiedmaterial is associated with strengthening the frame and giving it volumetric indicators. These profiles are designed to attach plasterboard to their base. Here it is important to pay attention to the following components:

Based on this data, CD profiles are installed. To do this, you need to: Types of profiles for plasterboard.

Types of profiles for plasterboard.

Return to Contents</a>

Wall finishing with plasterboard: installation features

Once the frame is installed, you canstart covering the walls (you can also do the ceiling with plasterboard yourself). Hidden communications are laid here, insulation and soundproofing of the walls is carried out. Mineral wool is cut into strips of a certain size and laid in the space between the main CD guides. The width of the insulating layer should be slightly larger than the dimensions of the profiles themselves. For these purposes, it is quite possible to use sheet forms of materials. Scheme of fastening of metal frame underplasterboard. At the final stage, the technology of finishing the frame is used. This stage of the work usually does not cause difficulties - it is enough just to fix the finished sheets of gypsum board, carefully adjusting them to the desired size. The gypsum is fastened with self-tapping screws for metal surfaces. Their estimated length is 3.5 cm. The distance at which they are fixed is 15-20 cm. Excessively strong immersion of the caps into the base of the sheet should be avoided, at the same time they should not protrude on the surface. For this, a special bit with a limiter is used. As is clear from all that has been said, the process of sheathing walls with gypsum board sheets is completely simple. Having understood the essence and rules of installation, even a beginner can do the work. A similar method is used and , since the process is almost similar. Recommendation! So that further activities on finishing the walls are not associated with problems in the form of cracks in the putty, it is worth performing certain actions. If the surface is supposed to be painted, you need to put a CD profile under the joints connecting the sheets, then screw the plasterboard on both sides with self-tapping screws. Return to the table of contents</a>

Scheme of fastening of metal frame underplasterboard. At the final stage, the technology of finishing the frame is used. This stage of the work usually does not cause difficulties - it is enough just to fix the finished sheets of gypsum board, carefully adjusting them to the desired size. The gypsum is fastened with self-tapping screws for metal surfaces. Their estimated length is 3.5 cm. The distance at which they are fixed is 15-20 cm. Excessively strong immersion of the caps into the base of the sheet should be avoided, at the same time they should not protrude on the surface. For this, a special bit with a limiter is used. As is clear from all that has been said, the process of sheathing walls with gypsum board sheets is completely simple. Having understood the essence and rules of installation, even a beginner can do the work. A similar method is used and , since the process is almost similar. Recommendation! So that further activities on finishing the walls are not associated with problems in the form of cracks in the putty, it is worth performing certain actions. If the surface is supposed to be painted, you need to put a CD profile under the joints connecting the sheets, then screw the plasterboard on both sides with self-tapping screws. Return to the table of contents</a>

Finishing of the ceiling with sheets GKL

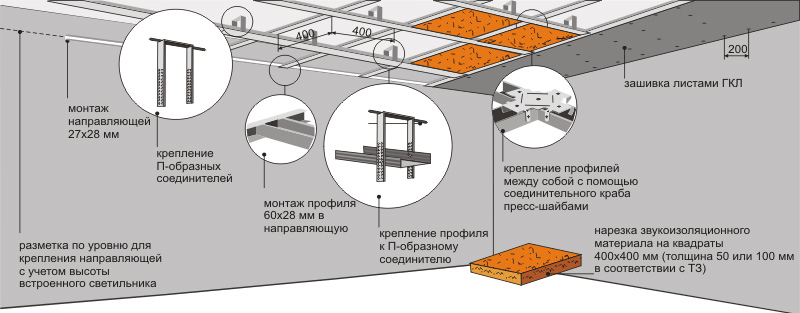

is associated with the use of such devices in work as: Scheme of finishing the ceiling with plasterboard.

Scheme of finishing the ceiling with plasterboard.

- level;

- roulette;

- perforator;

- scissors;

- construction knife;

- Screwdriver;

- awl or needle roller;

- putty knife;

- paint roller;

- emery cloth.

First, the surface is prepared: cleaning from the old coating, plaster and treating the seams with mounting foam. Ceiling sheathing comes down to going through the following stages, such as:

- marking;

- installation of the frame;

- Sheathing;

- processing.

First, the zero mark is found:the heights of all corners are measured, the lowest one is found, 60 mm are measured from it. Then they are marked with a building level and a line is drawn across the entire area of the room. Further plasterboard ceiling sheathing is associated with the installation of the profile. It is worth emphasizing that the frame is designed for a maximum weight of 15 kg, with heavy loads, cracks may appear on the base. For this reason, all parts of the erected structure should be carefully secured. Focusing on the previously designated marks, the guide profile is secured from the side of all walls at a distance of 300-400 mm. After that, a diagram is applied to the ceiling base. An acceptable option would be a 600 × 600 mm frame, it is often used for finishing single-level coverings with minimal loads. A 400 × 400 mm frame base is more durable and stable, it is used for multi-level ceilings and for wooden floors. According to the existing longitudinal lines, the suspended structures for the profiles are fixed. One of them is installed in a 300 mm partition, and the others - in 600 m. If it is necessary to lower the ceiling by 1 m or more, special hangers on springs with rods are used. The longitudinal guides are determined using special connecting elements - crabs. After installing the frame, you should do electrical work, bringing the wiring outside the profile. Then the plasterboard sheets are fixed to the frame structure with self-tapping screws specially designed for this material. The gap between the fixed parts should be minimal. The exception is the space between the wall and the plasterboard: here a gap of 5-10 mm is deliberately left. This method takes into account the temperature fluctuations of the material, which is very susceptible to changes in humidity and air temperature. Upon completion, the joints are puttied. A serpyanka bandage is glued to the still not dry composition, after which a layer of putty is applied to it again. Then the seam is sanded with fine-grained sandpaper. The quality of the work can be checked under artificial light. It will indicate possible errors in the work and the slightest irregularities. The surface of the plasterboard can be covered with any paint, the only exception being liquid glass. Before applying the enamel, the base must be carefully primed. Good luck!</ ul>