In any room, the ceiling is the most prominent partposition. This is the first thing that catches the eye, and its appearance creates the first impression of the entire house. Do-it-yourself ceiling plastering can improve the impression. Plastering the ceiling allows you to eliminate defectssurface and renew it. During construction, various defects and irregularities appear on the surface of the ceiling. In a residential building, stains, cracks, etc. appear on the ceiling over time. Do-it-yourself ceiling plastering allows you to eliminate surface defects and renew it.

Plastering the ceiling allows you to eliminate defectssurface and renew it. During construction, various defects and irregularities appear on the surface of the ceiling. In a residential building, stains, cracks, etc. appear on the ceiling over time. Do-it-yourself ceiling plastering allows you to eliminate surface defects and renew it.

Selection of plaster material

The plaster is a thick mixture,which is intended for finishing various surfaces. The process of plastering the ceiling involves applying plaster to the ceiling in order to create a smooth, even surface. In general, this process can be divided into plastering (primary removal of irregularities) and puttying (finishing surface leveling). The main requirements for the materials used: good adhesion to various materials used in construction; the ability to form a smooth surface in simple ways; monolithicity; resistance to external influences. Plastering building mixtures.Plasters can be divided into two large groups - cement-based and gypsum-based mixtures. To improve the functional properties and processability, various substances are added to the mixture. Cement mortar is a mixture of cement and sand in a ratio of 1: (3-4). To improve elasticity, cement-lime mortar is used, when lime milk is added to the cement-sand mixture (0.7-1 part of slaked lime diluted in water to a liquid state). Pure gypsum mortar is usually not used for plastering. Lime-gypsum mortar is widely used. It is a mixture of gypsum with lime mortar in a ratio of 1: (3-4). In turn, lime mortar is prepared as a mixture of slaked lime with sand in a ratio of 1: (4-6). Self-prepared solutions allow, but cannot provide the desired reliability. Currently, dry building mixtures are being sold, which significantly increase the reliability and quality of the material. The composition of such a mixture includes mineral and polymer additives, increasing their elasticity and strength. Their basis can be cement and gypsum.

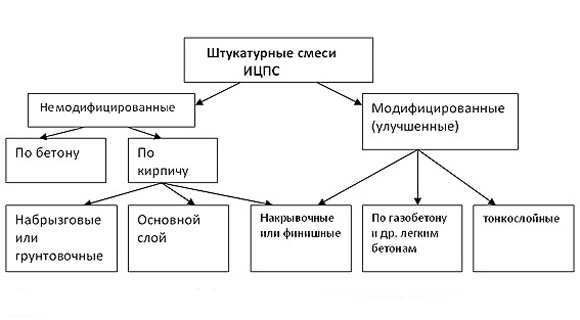

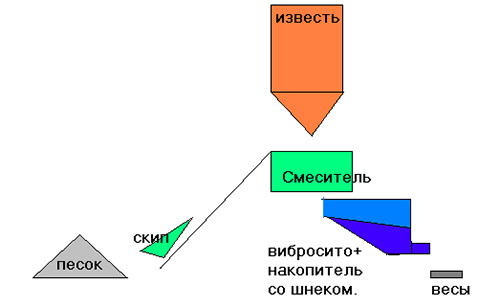

Plastering building mixtures.Plasters can be divided into two large groups - cement-based and gypsum-based mixtures. To improve the functional properties and processability, various substances are added to the mixture. Cement mortar is a mixture of cement and sand in a ratio of 1: (3-4). To improve elasticity, cement-lime mortar is used, when lime milk is added to the cement-sand mixture (0.7-1 part of slaked lime diluted in water to a liquid state). Pure gypsum mortar is usually not used for plastering. Lime-gypsum mortar is widely used. It is a mixture of gypsum with lime mortar in a ratio of 1: (3-4). In turn, lime mortar is prepared as a mixture of slaked lime with sand in a ratio of 1: (4-6). Self-prepared solutions allow, but cannot provide the desired reliability. Currently, dry building mixtures are being sold, which significantly increase the reliability and quality of the material. The composition of such a mixture includes mineral and polymer additives, increasing their elasticity and strength. Their basis can be cement and gypsum. Scheme of production of dry limeplaster mix. Dry gypsum-based building mixes are most often used for plastering ceilings. However, in rooms with high humidity and other exposure to various factors, cement-based mixtures for interior work should be used. Colored building mixes are produced for decorative plaster. In addition, the mixtures differ in the grain size of the additives, which should be taken into account when choosing a composition for plaster (grain size can exceed 2.5 mm) and putty (grain size no more than 0.3 mm). In general, dry building mixes are divided by purpose into the following types:

Scheme of production of dry limeplaster mix. Dry gypsum-based building mixes are most often used for plastering ceilings. However, in rooms with high humidity and other exposure to various factors, cement-based mixtures for interior work should be used. Colored building mixes are produced for decorative plaster. In addition, the mixtures differ in the grain size of the additives, which should be taken into account when choosing a composition for plaster (grain size can exceed 2.5 mm) and putty (grain size no more than 0.3 mm). In general, dry building mixes are divided by purpose into the following types:

- plaster alignment;

- protective covering;

- putty;

- primer;

- adhesive layer;

- color decoration.

Return to Contents</a>

Step-by-step instruction: preparation of the ceiling

Plastering the surface with your own hands beginswith the preparation of the ceiling surface. Preparation consists of cleaning the surface, removing obvious defects and the old ceiling covering (during repairs). First of all, you need to take measures for your own protection - there will be a lot of dust when cleaning the ceiling. You need to use glasses and a respirator. Before applying the plaster, it is necessary to cleanceiling surface and remove the old ceiling covering. Old coverings are removed with a sharp, hard spatula. First, remove as much paint and old plaster as possible. If the spatula does not completely remove the old covering, use an emery mesh, grinder or coarse sandpaper. Check the quality of the joints between the floor slabs. If the plaster is loose or crumbling, remove it. Plaster that does not give in when touched with a spatula remains in place. Difficulties can be caused by paint applied directly to concrete. If it does not give in with a spatula, special solutions will have to be used. For example, you can use an iodine aqueous solution (25 ml per 10 l of water). The solution is applied to the remaining paint and soaks it. After that, remove the paint with a spatula. Sometimes there are cases when after getting wet mold or fungi appear on the ceiling, to remove them it is necessary to treat the affected area with a solution of copper sulfate (5 g per 1 l of water). After all work on the ceiling, its surface is dried and thoroughly cleaned from dust. Return to the table of contents</a>

Before applying the plaster, it is necessary to cleanceiling surface and remove the old ceiling covering. Old coverings are removed with a sharp, hard spatula. First, remove as much paint and old plaster as possible. If the spatula does not completely remove the old covering, use an emery mesh, grinder or coarse sandpaper. Check the quality of the joints between the floor slabs. If the plaster is loose or crumbling, remove it. Plaster that does not give in when touched with a spatula remains in place. Difficulties can be caused by paint applied directly to concrete. If it does not give in with a spatula, special solutions will have to be used. For example, you can use an iodine aqueous solution (25 ml per 10 l of water). The solution is applied to the remaining paint and soaks it. After that, remove the paint with a spatula. Sometimes there are cases when after getting wet mold or fungi appear on the ceiling, to remove them it is necessary to treat the affected area with a solution of copper sulfate (5 g per 1 l of water). After all work on the ceiling, its surface is dried and thoroughly cleaned from dust. Return to the table of contents</a>

Plastering tools

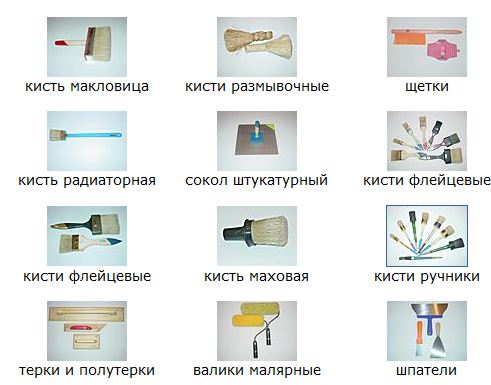

Plastering the ceiling is done using specialized hand tools. To plaster the ceiling, you will need the following tools: Tools for plastering ceilings.

Tools for plastering ceilings.

- putty knife;

- grater;

- semifunctional;

- falcon;

- stucco trowel;

- plaster blade;

- the equalizer angular;

- rule;

- trowel (malk);

- scoop;

- an ironing board;

- level;

- hatchet;

- roller or paint brushes;

- sandpaper;

- sandpaper.

For ease of work, you should prepare a setspatulas of different hardness and width from 50 to 120 mm. In addition, it is advisable to have a comb spatula. To prepare the solution, you need a container for the mixture, a mixer or a drill with a mixer attachment. Quality control should be carried out using a level. Return to the table of contents</a>

Aligning the ceiling

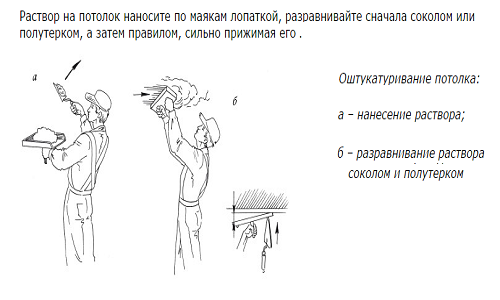

Do-it-yourself plastering of the surfacebegins with its alignment. The first stage of ceiling alignment is priming the surface in order to cover large defects and ensure good adhesion. Ceiling priming is done in two layers. The primer mixture is applied to the entire surface of the ceiling with a roller, and in the corners - with a brush. Before applying plaster, the primer layer must dry completely. The process of plastering the ceiling.The plastering mixture is prepared as follows. Water is poured into a container and the dry mixture is added in the proportions specified in the instructions. The mixture is mixed with a drill with a mixer attachment and then left to stand for 5-10 minutes. After this, the solution is finally mixed with a drill until a homogeneous mass of the consistency of thick sour cream is obtained. The plaster is applied to the ceiling surface using a spatula and trowel. Plastering of the ceiling should begin from the corner of the wall with a window. The solution is applied to the surface and immediately leveled with a spatula. The ceiling is plastered evenly over the entire surface of the ceiling. The coating thickness is about 5-10 mm. The work is completed by applying putty over the dried plaster. The putty mixture is prepared in the same way as the plaster mixture. It is applied in a thin layer of 3-5 mm and carefully leveled with a spatula. After drying, it is sanded with sandpaper. Return to the table of contents</a>

The process of plastering the ceiling.The plastering mixture is prepared as follows. Water is poured into a container and the dry mixture is added in the proportions specified in the instructions. The mixture is mixed with a drill with a mixer attachment and then left to stand for 5-10 minutes. After this, the solution is finally mixed with a drill until a homogeneous mass of the consistency of thick sour cream is obtained. The plaster is applied to the ceiling surface using a spatula and trowel. Plastering of the ceiling should begin from the corner of the wall with a window. The solution is applied to the surface and immediately leveled with a spatula. The ceiling is plastered evenly over the entire surface of the ceiling. The coating thickness is about 5-10 mm. The work is completed by applying putty over the dried plaster. The putty mixture is prepared in the same way as the plaster mixture. It is applied in a thin layer of 3-5 mm and carefully leveled with a spatula. After drying, it is sanded with sandpaper. Return to the table of contents</a>

Plaster for beacons

When processing a fairly uneven ceilingthe plaster must have a layer of increased thickness. In this case, the plastering method on beacons is used. The essence of the method is that plastic beacons of different heights are attached to the entire surface of the ceiling, which form the same level at their top. The beacons are attached to gypsum or cement patches every 30 cm. After the patches have dried, having secured the beacons, the plaster is applied with alignment at their tops. The thickness of such a layer reaches 5 cm in places of the largest dents on the ceiling. Control over the correct installation of beacons is carried out using a 2 m long level. After the work is completed, the beacons are removed. Return to the table of contents</a>

Plasterboard ceiling from plasterboard

consists of applying putty.First, a mounting mesh (serpyanka) is applied to the joints of the plasterboard sheets. The joint areas and the places where the plasterboard is fastened with screws are carefully filled with putty. Then a thin layer of primer is applied to the entire surface of the plasterboard. After it dries, a 2-3 mm thick layer of putty mixture is laid on the plasterboard. The surface is rubbed and sanded using a sanding mesh. Plastering the ceiling with your own hands is not a complicated process, but it requires accuracy and thoroughness in finishing. When plastering, you should use standard high-quality mixtures, then a good appearance of the surface will be ensured.