Depending on the material from whichwalls are made, and there are also different ways of finishing them. Thus, despite the apparent simplicity, plastering concrete walls is a rather complex undertaking, during which it is necessary to adhere to certain rules and recommendations. Concrete walls are often curved,therefore, before finishing, they must be plastered. Today, concrete is a fairly common material, distinguished not only by good performance characteristics, but also by the curvature of the surface. That is why leveling the walls with your own hands using plaster is necessary to give the apartment an aesthetically attractive appearance. In addition, this way you can eliminate a strong slope and cracks.

Concrete walls are often curved,therefore, before finishing, they must be plastered. Today, concrete is a fairly common material, distinguished not only by good performance characteristics, but also by the curvature of the surface. That is why leveling the walls with your own hands using plaster is necessary to give the apartment an aesthetically attractive appearance. In addition, this way you can eliminate a strong slope and cracks.

Preparatory work for plastering

Before you start applying plaster,it is necessary to thoroughly clean the walls. The advantages of plastering are difficult to overestimate. Plaster not only protects against moisture, allowing air to pass through and having the ability to breathe, but also gives the treated surface excellent heat and sound insulation characteristics. Using different types of plaster, you can get a variety of surface textures. When starting work on applying plaster to concrete, it is necessary to take into account the importance of this work: a smooth and durable surface is the key to the quality of the coating for the entire period of its operation. If the work is carried out correctly, the plaster layer will last a long time without cracking or crumbling. Before plastering concrete walls, the following conditions must be met:

Before you start applying plaster,it is necessary to thoroughly clean the walls. The advantages of plastering are difficult to overestimate. Plaster not only protects against moisture, allowing air to pass through and having the ability to breathe, but also gives the treated surface excellent heat and sound insulation characteristics. Using different types of plaster, you can get a variety of surface textures. When starting work on applying plaster to concrete, it is necessary to take into account the importance of this work: a smooth and durable surface is the key to the quality of the coating for the entire period of its operation. If the work is carried out correctly, the plaster layer will last a long time without cracking or crumbling. Before plastering concrete walls, the following conditions must be met:

- The surface of the walls must be thoroughly cleaned from dirt and dust;

- The concrete should be rough.

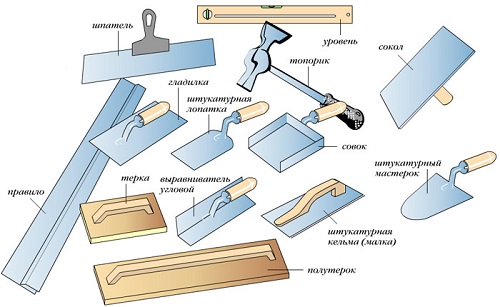

In order to process the walls yourself, you need to prepare the following materials and tools: Tools for plastering walls.

Tools for plastering walls.

- scrapers and brushes;

- putty knife;

- chisel or jackhammer;

- a hammer;

- plaster;

- glass fabric mesh;

- level and plumb bob;

- rule;

- raki, which will be used as beacons;

- a primer.

The technology of wall preparation involves the beginningworks with the removal of the old decorative coating (paint or wallpaper). This is usually done with a spatula. Then the entire surface is carefully tapped with a hammer to detect loose plaster or putty. In places where the coating needs to be replaced, the blows will be loud. Loose putty is removed from concrete walls with a spatula. This process will create a new base that guarantees a strong adhesion of the plaster layer to the concrete. If the work is carried out in new buildings where plastering has not yet been done, it is necessary to take care to clean the walls from formwork lubricant. This can be done with brushes and scrapers or ordinary water supplied under high pressure. When the surface is clean, it should be notched, which will allow the concrete to bond more firmly to the plaster layer. Notches are usually made with a jackhammer, but if you do not have one, you can use a chisel or a chisel. Return to the table of contents</a>

Work on priming

Plastering of concrete walls cannot be carried outwithout preliminary priming of the surface. It is the primer composition that allows to increase the reliability of the structure and extend the service life of the finish. The primer significantly improves the adhesion of the plaster layer to concrete, the putty layer to the plaster, and the paint layer to the putty. Priming the walls is necessary for improvementadhesion of plaster to concrete. In addition, applying a primer can improve the properties of the surface. Concrete becomes more moisture-resistant, less susceptible to fungus and mold, rotting and other negative factors. It dries faster after applying the finishing layer. For monolithic concrete walls with a dense structure, a mineral-based primer is usually used, in which cement serves as a binder. Experts recommend using a primer called concrete contact. This material can stabilize concrete walls for applying gypsum and other plasters. Return to contents</a>

Priming the walls is necessary for improvementadhesion of plaster to concrete. In addition, applying a primer can improve the properties of the surface. Concrete becomes more moisture-resistant, less susceptible to fungus and mold, rotting and other negative factors. It dries faster after applying the finishing layer. For monolithic concrete walls with a dense structure, a mineral-based primer is usually used, in which cement serves as a binder. Experts recommend using a primer called concrete contact. This material can stabilize concrete walls for applying gypsum and other plasters. Return to contents</a>

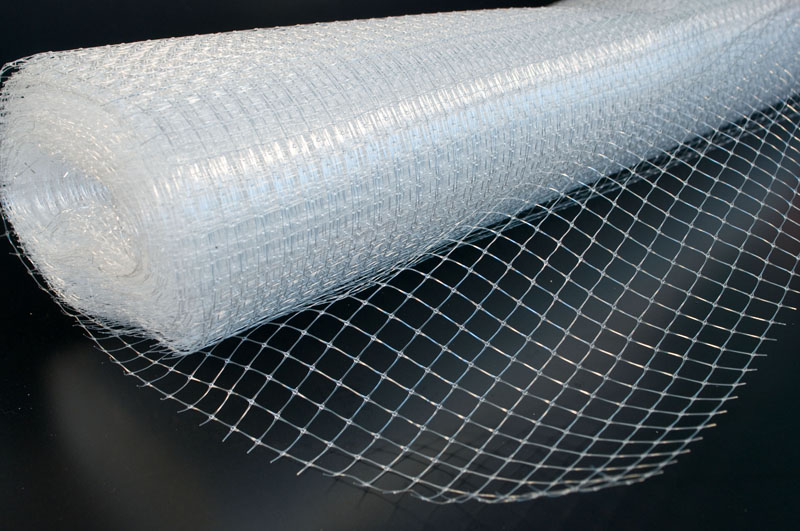

Application of a grid for plastering works

Plaster mesh is used in the case where:when the plaster layer exceeds 2 cm. In cases where the thickness of the plaster layer exceeds 2 cm or there is no confidence in its strong adhesion to the base, it is recommended to use a special plaster mesh. Such a fiberglass mesh can have a different cross-section, but it is desirable that the cell size does not exceed 5x5 mm. By applying the mesh, an internal frame is formed that holds the plaster layer on the concrete. It is necessary when finishing concrete walls with your own hands in rooms with high temperature and humidity differences and the risk of mechanical impacts. The mesh laid on the primer layer must be stretched as tightly as possible, otherwise the mesh will begin to vibrate and the plaster will soon crack and fall off. To protect the mesh from corrosion, it is recommended to paint it with oil paint or cement milk before use. Return to contents</a>

Plaster mesh is used in the case where:when the plaster layer exceeds 2 cm. In cases where the thickness of the plaster layer exceeds 2 cm or there is no confidence in its strong adhesion to the base, it is recommended to use a special plaster mesh. Such a fiberglass mesh can have a different cross-section, but it is desirable that the cell size does not exceed 5x5 mm. By applying the mesh, an internal frame is formed that holds the plaster layer on the concrete. It is necessary when finishing concrete walls with your own hands in rooms with high temperature and humidity differences and the risk of mechanical impacts. The mesh laid on the primer layer must be stretched as tightly as possible, otherwise the mesh will begin to vibrate and the plaster will soon crack and fall off. To protect the mesh from corrosion, it is recommended to paint it with oil paint or cement milk before use. Return to contents</a>

Rules for plastering walls

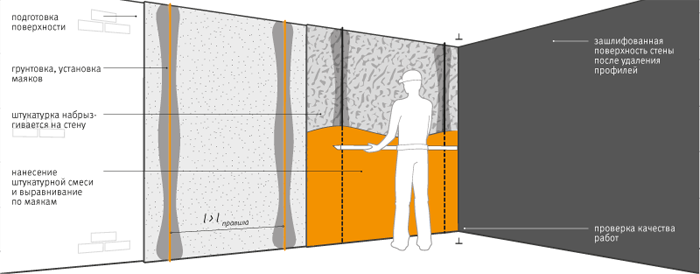

Scheme of plastering a wall using beacons.Immediately before plastering, a number of measures should be taken. Thus, it is necessary to check the wall surface for verticality and horizontality of planes. In order for plastering to be carried out as competently as possible, beacons should be installed over the entire surface being treated. Evenly installed rows of slats should divide the surface into sections. The distance between the beacons should be no more than 1 m. Then the plaster is prepared. In this case, it is advisable to use the instructions printed by the manufacturer on the packaging with the composition. When applying, the thickness of the plaster layer should not exceed 0.5 cm. The slats, acting as beacons and dividing the wall into uniform sections, will allow you to carry out the work efficiently and quickly. After applying wet plaster, the wall must be well moistened with water. If a composition called dry plaster was used, it only needs to be slightly moistened. As a rule, plastering work begins from the corners of the room. A layer of mortar is applied to each section separated by slats. Then, using a rule that is passed along the slats, the excess mortar is removed. The process is repeated until all sections of the wall are plastered. Once finished, the mortar is left to dry completely. When the composition sets and hardens, the beacons are carefully removed. The grooves left by the slats are filled with plaster and left to dry. The plastering work is completed by rubbing and smoothing the coatings using sandpaper or a special wooden float. Using the information provided, you can successfully level concrete walls and qualitatively prepare them for finishing.</ ul>

Scheme of plastering a wall using beacons.Immediately before plastering, a number of measures should be taken. Thus, it is necessary to check the wall surface for verticality and horizontality of planes. In order for plastering to be carried out as competently as possible, beacons should be installed over the entire surface being treated. Evenly installed rows of slats should divide the surface into sections. The distance between the beacons should be no more than 1 m. Then the plaster is prepared. In this case, it is advisable to use the instructions printed by the manufacturer on the packaging with the composition. When applying, the thickness of the plaster layer should not exceed 0.5 cm. The slats, acting as beacons and dividing the wall into uniform sections, will allow you to carry out the work efficiently and quickly. After applying wet plaster, the wall must be well moistened with water. If a composition called dry plaster was used, it only needs to be slightly moistened. As a rule, plastering work begins from the corners of the room. A layer of mortar is applied to each section separated by slats. Then, using a rule that is passed along the slats, the excess mortar is removed. The process is repeated until all sections of the wall are plastered. Once finished, the mortar is left to dry completely. When the composition sets and hardens, the beacons are carefully removed. The grooves left by the slats are filled with plaster and left to dry. The plastering work is completed by rubbing and smoothing the coatings using sandpaper or a special wooden float. Using the information provided, you can successfully level concrete walls and qualitatively prepare them for finishing.</ ul>