Since ancient times, one of the main types of wall finishing is plaster. When planning to plaster walls, the consumption of materials determines the choice of the type of finishing. Calculation of the amount of plaster solution.A wide range of solutions is used and offered for plastering walls. Numerous dry building mixtures are made on various bases and are ready to satisfy any requirement. Plastering solution can be prepared by hand, and it will not be inferior in quality to a purchased mixture. All this suggests that when plastering is planned, the consumption of materials should be carried out correctly and reliably.

Calculation of the amount of plaster solution.A wide range of solutions is used and offered for plastering walls. Numerous dry building mixtures are made on various bases and are ready to satisfy any requirement. Plastering solution can be prepared by hand, and it will not be inferior in quality to a purchased mixture. All this suggests that when plastering is planned, the consumption of materials should be carried out correctly and reliably.

Material Features

Plaster is a finishing layer,preparing the wall for the final coating. The consumption of materials varies significantly depending on the type of plastering. There are three types of plaster according to their purpose:

Classification of plaster.Each type of finish is applied in the form of a layer of different thickness and a different solution, both in composition and consistency. The type of plaster and the consumption of materials depend on what the wall is made of. Thus, only two layers are usually applied over chipboard or plasterboard - rough and final. Brick requires mandatory application of all three layers. Concrete, as a rule, is plastered in three layers, but with high-quality wall production, two-layer plaster can be used. The type of plaster also depends on the location of the wall, i.e. on external influencing factors. External and internal walls are distinguished, as well as internal walls exposed to moisture and steam (bathroom, sauna). Finally, the curvature of the surface, its defects and the degree of deviation from the vertical significantly affect the consumption of materials and the thickness of the main layer of plaster. Covering the walls with chipboard or plasterboard significantly reduces the consumption of materials, since the verticality of the wall and the smoothness of the main part of the surface (except for the seams) are ensured. Thus, when plastering work is carried out, the consumption of materials depends on the construction of the wall, the type of plaster and the degree of curvature or defectiveness of the surface. Return to contents</a>

Classification of plaster.Each type of finish is applied in the form of a layer of different thickness and a different solution, both in composition and consistency. The type of plaster and the consumption of materials depend on what the wall is made of. Thus, only two layers are usually applied over chipboard or plasterboard - rough and final. Brick requires mandatory application of all three layers. Concrete, as a rule, is plastered in three layers, but with high-quality wall production, two-layer plaster can be used. The type of plaster also depends on the location of the wall, i.e. on external influencing factors. External and internal walls are distinguished, as well as internal walls exposed to moisture and steam (bathroom, sauna). Finally, the curvature of the surface, its defects and the degree of deviation from the vertical significantly affect the consumption of materials and the thickness of the main layer of plaster. Covering the walls with chipboard or plasterboard significantly reduces the consumption of materials, since the verticality of the wall and the smoothness of the main part of the surface (except for the seams) are ensured. Thus, when plastering work is carried out, the consumption of materials depends on the construction of the wall, the type of plaster and the degree of curvature or defectiveness of the surface. Return to contents</a>

Features of plaster compositions

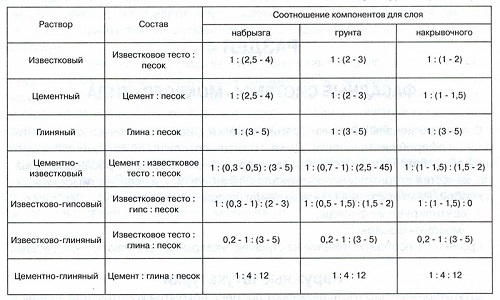

Consumption of plaster per 1 m2.Plastering can be done with a ready-made mixture or a homemade solution. There are several main types of homemade compositions. Cement-sand mortar is made as a mixture of cement and sand in a ratio of 1: (2-6). In the final layer, the amount of sand can increase. Cement for work is mainly grade M400 for external coatings and M200 for internal work. Cement-lime-sand mortar is prepared from a mixture of cement, slaked lime and sand in a ratio of 1:1: (3-5). Lime and sand are mixed together to obtain lime dough, after which they are mixed with cement. Lime-gypsum mortar consists of a mixture of gypsum with lime dough in a ratio of 1: (3-4). In turn, lime dough is mixed slaked lime and sand in a ratio of 1:3. Lime-clay mortar contains a mixture of clay with sand and slaked lime in the ratio of 1:0.4:(3-6). Lime mortar is a mixture of slaked lime with sand in the ratio of 1:(3-5). Cement-sand mortars are very popular. According to the cement content, mortars are divided into lean (ratio of 1:5 or more sand); fat (ratio of 1:2) and normal with a ratio of 1:(3-4). The most durable mortars are fat types, but they can crack. In addition, they have an increased cement consumption, which leads to an increase in the cost of the composition. Lean types are the least susceptible to cracking, which determines their use in the final layer. According to density, mortars are divided into a heavy type (more than 1500 kg / m³) and a light type (less than 1500 kg / m³). The most widely used for interior work is the more plastic cement-lime-sand mortar.

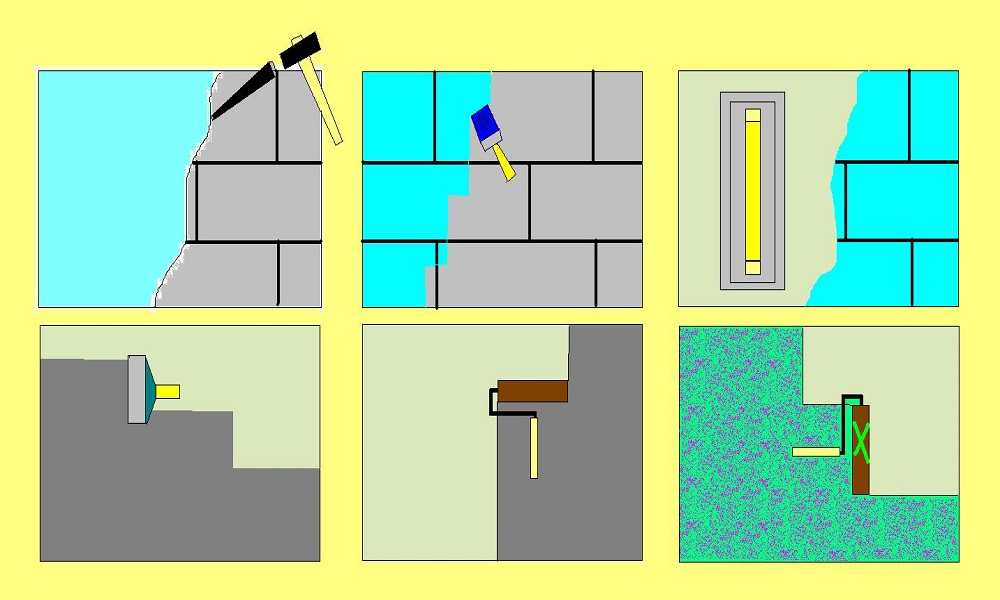

Consumption of plaster per 1 m2.Plastering can be done with a ready-made mixture or a homemade solution. There are several main types of homemade compositions. Cement-sand mortar is made as a mixture of cement and sand in a ratio of 1: (2-6). In the final layer, the amount of sand can increase. Cement for work is mainly grade M400 for external coatings and M200 for internal work. Cement-lime-sand mortar is prepared from a mixture of cement, slaked lime and sand in a ratio of 1:1: (3-5). Lime and sand are mixed together to obtain lime dough, after which they are mixed with cement. Lime-gypsum mortar consists of a mixture of gypsum with lime dough in a ratio of 1: (3-4). In turn, lime dough is mixed slaked lime and sand in a ratio of 1:3. Lime-clay mortar contains a mixture of clay with sand and slaked lime in the ratio of 1:0.4:(3-6). Lime mortar is a mixture of slaked lime with sand in the ratio of 1:(3-5). Cement-sand mortars are very popular. According to the cement content, mortars are divided into lean (ratio of 1:5 or more sand); fat (ratio of 1:2) and normal with a ratio of 1:(3-4). The most durable mortars are fat types, but they can crack. In addition, they have an increased cement consumption, which leads to an increase in the cost of the composition. Lean types are the least susceptible to cracking, which determines their use in the final layer. According to density, mortars are divided into a heavy type (more than 1500 kg / m³) and a light type (less than 1500 kg / m³). The most widely used for interior work is the more plastic cement-lime-sand mortar. Scheme of high-quality plasteringwalls on slatted beacons. In order to make the solution more plastic and elastic, various additives are used, for example, detergents (laundry soap, shampoo, etc.). To increase the setting time of the solution and increase elasticity, PVA glue or wood glue is added. Such additives usually do not exceed 2-5% by weight. Recently, ready-made dry mixes have been actively used. The most common compositions include dry plaster options based on cement for external and internal work, as well as finishing putty mixtures on the same basis. Dry plaster and putty mixture on a gypsum base is suitable for interior decoration. Special and quite effective compositions include dry decorative plaster, "Bark beetle" mixture for external walls, Venetian plaster, "Optimist" mixture, "Volma" finishing plaster and a number of others. Return to contents</a>

Scheme of high-quality plasteringwalls on slatted beacons. In order to make the solution more plastic and elastic, various additives are used, for example, detergents (laundry soap, shampoo, etc.). To increase the setting time of the solution and increase elasticity, PVA glue or wood glue is added. Such additives usually do not exceed 2-5% by weight. Recently, ready-made dry mixes have been actively used. The most common compositions include dry plaster options based on cement for external and internal work, as well as finishing putty mixtures on the same basis. Dry plaster and putty mixture on a gypsum base is suitable for interior decoration. Special and quite effective compositions include dry decorative plaster, "Bark beetle" mixture for external walls, Venetian plaster, "Optimist" mixture, "Volma" finishing plaster and a number of others. Return to contents</a>

Calculation of material consumption

First estimate of material consumptionplastering of the wall is carried out without taking into account a number of factors, simply by the area of the coating. For example, the wall has an area of 20 m². The thickness of the base layer is 5 cm, i.e. 0.05 m. An elementary calculation shows that the volume of plaster is 1 m³ or, in terms of the volume of water, 1000 liters. A mixture of cement and sand in a ratio of 1:3 by volume is used. Therefore, the cement consumption for plastering the walls will be 1:4 = 0.25 m², and the sand consumption is 0.75 m³. With a cement density of 1600 kg / m³, the weight consumption of cement for the work will be 400 kg. If a cement-lime-sand mortar is used in a ratio of 1:1:4, then similar calculations show that the cement consumption will be 0.17 m³, or 272 kg. Return to the table of contents</a>

Accounting for some factors

Wall plastering scheme.In practice, a wall always has a certain curvature. Accurately accounting for this factor requires numerous measurements and calculations, which does not make much sense. An approximate accounting of the curvature of the wall can be made by introducing the average thickness of the actual layer into the calculation. To do this, determine the minimum and maximum thickness of the plaster layer, and find the average value of this value. For example, the minimum thickness was 14 mm, and the maximum thickness was 32 mm. Therefore, the average value will be (44 + 52) / 2 = 48 mm. Taking this value into account, the previous calculations are recalculated. In the preliminary calculation, the wall area was taken as the area of a regular rectangle, i.e. as the product of the length and the height of the surface. In the actual calculations, it is necessary to take into account the deviation in wall height and parallelism. The average height of the wall and its average length are taken into account. Measurements are made at three points - in the center and at the edges. The value is averaged over the three values. In addition, the deviation of the angles from 90 ° is taken into account. The underestimation of the area due to this defect is simply subtracted from the calculated value. A more accurate calculation of the rough layer is complicated by the exact measurement of the defect sizes. The calculation should take into account the sizes of the largest defects. For example, when taking into account the rough layer on a chipboard coating, the approximate volume of the seam between the sheets is calculated as the product of the seam length by the gap width and the thickness of the chipboard sheet. Most often, the accuracy of the calculations is not needed. A preliminary estimate gives a slightly overestimated consumption of materials, which may be useful when carrying out other construction work. This occurs because the thickness of the main layer of plaster is standardized by the maximum size. Return to the table of contents</a>

Wall plastering scheme.In practice, a wall always has a certain curvature. Accurately accounting for this factor requires numerous measurements and calculations, which does not make much sense. An approximate accounting of the curvature of the wall can be made by introducing the average thickness of the actual layer into the calculation. To do this, determine the minimum and maximum thickness of the plaster layer, and find the average value of this value. For example, the minimum thickness was 14 mm, and the maximum thickness was 32 mm. Therefore, the average value will be (44 + 52) / 2 = 48 mm. Taking this value into account, the previous calculations are recalculated. In the preliminary calculation, the wall area was taken as the area of a regular rectangle, i.e. as the product of the length and the height of the surface. In the actual calculations, it is necessary to take into account the deviation in wall height and parallelism. The average height of the wall and its average length are taken into account. Measurements are made at three points - in the center and at the edges. The value is averaged over the three values. In addition, the deviation of the angles from 90 ° is taken into account. The underestimation of the area due to this defect is simply subtracted from the calculated value. A more accurate calculation of the rough layer is complicated by the exact measurement of the defect sizes. The calculation should take into account the sizes of the largest defects. For example, when taking into account the rough layer on a chipboard coating, the approximate volume of the seam between the sheets is calculated as the product of the seam length by the gap width and the thickness of the chipboard sheet. Most often, the accuracy of the calculations is not needed. A preliminary estimate gives a slightly overestimated consumption of materials, which may be useful when carrying out other construction work. This occurs because the thickness of the main layer of plaster is standardized by the maximum size. Return to the table of contents</a>

Consumption of standard mixtures

When using ready-made mixturesyou should be guided by the recommendations for material consumption indicated on the packaging. For example, some typical consumption rates of ready-made mixtures at recommended plaster thicknesses should be given. A gypsum plaster mixture when applied to a 10 mm thick chipboard wall will have a recommended consumption rate of 9 kg/m². The cement consumption in the mixture will be on average 16-18 kg/m². Decorative plaster will require about 8 kg/m³. Of other types of plaster solutions, the following consumption per 1 m² can be noted:

- "Vetonit" - 1.5 kg;

- "Rotbend" - 8.5 kg (with a layer thickness of 5 cm);

- "Bark beetle" - up to 3 kg;

- Venetian plaster - 0.2 kg.

Return to Contents</a>

Necessary materials

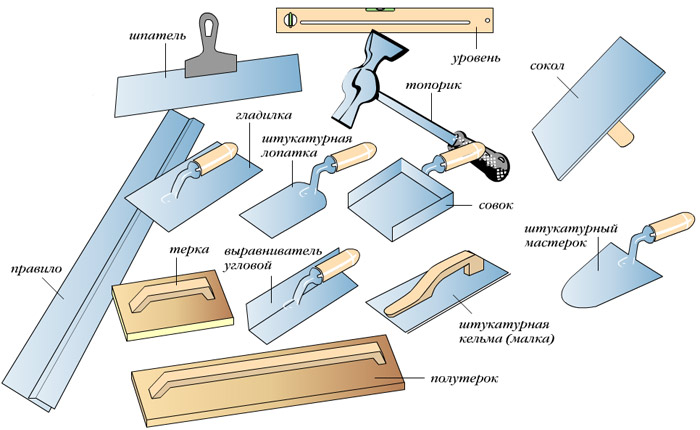

Tools needed for plastering. The following materials are usually used when plastering walls:

Tools needed for plastering. The following materials are usually used when plastering walls:

- cement M200 and M400;

- sand sifted with medium grains (preferably, river quartz);

- lime slaked or lime dough;

- gypsum building;

- clay (alumina);

- purified water;

- joiner glue;

- PVA glue;

- dry plaster mixture for interior and exterior works.

When plastering work is carried out, it is necessaryPlan the consumption of materials in advance so that there is no need to compensate for shortages. An unexpected stop in work can affect the quality of plastering work.