Plastering is one of the most importantstages both in the construction of a house and in its renovation. Many home craftsmen want to know better how to plaster walls with their own hands in order to do this work themselves. Interest in this process arises for obvious reasons. Among them is the high price for the work that hired plasterers will do, and the healthy curiosity of a person who wants to be able to do, if not everything, then a lot himself. The main thing in plastering walls is calculating the required volume of plaster and selecting the optimal solution.

The main thing in plastering walls is calculating the required volume of plaster and selecting the optimal solution.

Advantages of plastering

Some qualities are unique, so itdifficult to replace with other finishing materials. After all, the solution is not only used to level surfaces, which, for example, plasterboard successfully (and with low labor costs) copes with. Plaster strengthens surfaces, fills voids, protects walls from the effects of adverse external factors (the list can be continued). With the advent of more modern fillers on the market, plaster began to perform not only the functions listed above, it turned into one of the finishing materials that are used in wall cladding. Yes, plastering walls is a labor-intensive operation, but knowing the rules of this process, you can cope with it yourself, gaining invaluable experience that will come in handy more than once, and saving significant funds. Return to contents</a>

Preparation of surfaces for plastering

Scheme of preparing a wall for plastering.However, we need to move from words to deeds. Of course, you know that plastering walls with your own hands, like any serious work, begins with the preparatory stage. Both newly erected walls and surfaces to which the solution has already been applied earlier need to be prepared for plastering. Correctly carried out preparatory activities before plastering will guarantee that after its application, the walls will serve "faithfully and truly" for a very long time. Preparation for plastering a wall begins with cleaning its surface. All old coatings must be removed from it down to the very base. It is desirable that the old plaster be removed from the wall as well (the older it is, the less suitable it is for restoration). Keep in mind that the wall must also be cleaned of paint, because there is no worse base in terms of adhesion than a painted surface. In fairness, it should be said that removing paint that has eaten deep into the wall is is not an easy task, but making notches, processing with special primers (betonokontakt, for example) or abrasives is only a half-measure. Therefore, you need to try to remove the paint, knock it out, and finally cut it out of the wall. You also need to remove greasy stains from the wall, since the plaster will not have contact with them. Solvents, soda, soap solutions, and even high-fat clay are used for this. The contaminated areas are smeared with it, and after drying, the clay is removed, and the wall area is washed with water. This procedure has to be repeated several times. Return to the table of contents</a>Preparation of concrete and brick bases Bases made of different materials interact with plaster in different ways, so there are some differences in their preparation.

Scheme of preparing a wall for plastering.However, we need to move from words to deeds. Of course, you know that plastering walls with your own hands, like any serious work, begins with the preparatory stage. Both newly erected walls and surfaces to which the solution has already been applied earlier need to be prepared for plastering. Correctly carried out preparatory activities before plastering will guarantee that after its application, the walls will serve "faithfully and truly" for a very long time. Preparation for plastering a wall begins with cleaning its surface. All old coatings must be removed from it down to the very base. It is desirable that the old plaster be removed from the wall as well (the older it is, the less suitable it is for restoration). Keep in mind that the wall must also be cleaned of paint, because there is no worse base in terms of adhesion than a painted surface. In fairness, it should be said that removing paint that has eaten deep into the wall is is not an easy task, but making notches, processing with special primers (betonokontakt, for example) or abrasives is only a half-measure. Therefore, you need to try to remove the paint, knock it out, and finally cut it out of the wall. You also need to remove greasy stains from the wall, since the plaster will not have contact with them. Solvents, soda, soap solutions, and even high-fat clay are used for this. The contaminated areas are smeared with it, and after drying, the clay is removed, and the wall area is washed with water. This procedure has to be repeated several times. Return to the table of contents</a>Preparation of concrete and brick bases Bases made of different materials interact with plaster in different ways, so there are some differences in their preparation. Scheme of jointing and application of primer onbrick wall. In brickwork (this also includes blockwork), it is necessary to make seams up to 1 cm deep so that the solution fills these cavities and thus increases adhesion to the surface. If the wall is made of smooth brick, then it is additionally necessary to make frequent short notches on it with an axe, chisel or other tool, directed in different directions. This way you will get a surface that can contact with the solution. Notches are also made in a smooth concrete wall. The grooves should not be less than 3 mm deep and 1.5 cm long, they should be directed in different directions and located from each other at a distance of no more than the width of a matchbox. Of course, the walls should be cleaned of dust and treated with primers. But it is even better if the walls are impregnated with antiseptic compounds before applying the primer. It is worth remembering that the application of impregnations should be carried out alternately and only as the previous composition dries. Return to Contents</a>Preparing wooden walls Plastering wallsis done with your own hands not only on concrete and brick surfaces. Plastering is also used when repairing wooden walls. It is difficult to imagine such incompatible materials as wood and cement-sand mortar. However, a wooden base can be prepared so that the plaster will last for a long time. First of all, the wall must be cleaned, treated with an antiseptic and impregnated with a primer. After that, 2 layers of shingles are attached to it, which are stuffed diagonally. Shingles are 3-5 mm thick slats. They are nailed in the following way.

Scheme of jointing and application of primer onbrick wall. In brickwork (this also includes blockwork), it is necessary to make seams up to 1 cm deep so that the solution fills these cavities and thus increases adhesion to the surface. If the wall is made of smooth brick, then it is additionally necessary to make frequent short notches on it with an axe, chisel or other tool, directed in different directions. This way you will get a surface that can contact with the solution. Notches are also made in a smooth concrete wall. The grooves should not be less than 3 mm deep and 1.5 cm long, they should be directed in different directions and located from each other at a distance of no more than the width of a matchbox. Of course, the walls should be cleaned of dust and treated with primers. But it is even better if the walls are impregnated with antiseptic compounds before applying the primer. It is worth remembering that the application of impregnations should be carried out alternately and only as the previous composition dries. Return to Contents</a>Preparing wooden walls Plastering wallsis done with your own hands not only on concrete and brick surfaces. Plastering is also used when repairing wooden walls. It is difficult to imagine such incompatible materials as wood and cement-sand mortar. However, a wooden base can be prepared so that the plaster will last for a long time. First of all, the wall must be cleaned, treated with an antiseptic and impregnated with a primer. After that, 2 layers of shingles are attached to it, which are stuffed diagonally. Shingles are 3-5 mm thick slats. They are nailed in the following way. Preparing wooden surfaces for plastering.

Preparing wooden surfaces for plastering.

It should be noted that the shingles beforethe lathing device must be wetted. In this case, nails entering the slats will not be able to split them. Before plastering, the surface of the wooden wall must be moistened. Instead of lathing from laths, the wooden surface can be reinforced with a metal mesh or wire. The wire is stretched between the nails and wrapped under their heads, and the nails themselves are driven into the wall in a checkerboard pattern. The distance between them should not exceed 10 cm. Before plastering the wall, the metal reinforcement should be sprayed with liquid diluted cement. Return to contents</a>What to do with metal? Tools for plastering.Now we need to mention the preparation for plastering metal. It happens that steel lintels, etc. are embedded in the wall. The solution will not stick to the metal, so the surface of the lintel must also be reinforced. You can weld or attach a mesh to it with self-tapping screws for metal. Only the reinforcement should also extend to the area near the metal product. The steel surfaces themselves must be freed from any kind of coating (for example, paint) and degreased. By the way, if you can’t get rid of the paint on the wall, you can still reinforce the wall by tightly pressing the reinforcement with dowel nails. All preparatory measures, except for cleaning the walls from the old coating, are also applicable to surfaces that will be plastered for the first time. Return to the table of contents</a>

Tools for plastering.Now we need to mention the preparation for plastering metal. It happens that steel lintels, etc. are embedded in the wall. The solution will not stick to the metal, so the surface of the lintel must also be reinforced. You can weld or attach a mesh to it with self-tapping screws for metal. Only the reinforcement should also extend to the area near the metal product. The steel surfaces themselves must be freed from any kind of coating (for example, paint) and degreased. By the way, if you can’t get rid of the paint on the wall, you can still reinforce the wall by tightly pressing the reinforcement with dowel nails. All preparatory measures, except for cleaning the walls from the old coating, are also applicable to surfaces that will be plastered for the first time. Return to the table of contents</a>

Plastering

Sufficiently smooth walls can be coveredwith a solution without beacons. To assess the degree of curvature of the walls, you need to apply a building level to different areas of the surface. Plastering the wall should begin with splashing the surface with a solution diluted more liquid than the compositions of the subsequent layers. In this way, additional priming of the wall is carried out. The thickness of the first layer on brick, concrete and similar surfaces is about ½ cm, and a layer up to 1 cm thick is applied to wooden walls. The splash solution can be thrown with a ladle, trowel and even a whitewash brush. The list of tools for plastering looks like this:

- level;

- grater;

- semifunctional;

- an ironing board;

- rule;

- Master OK;

- falcon;

- angular equalizer.

Their diversity should not scare you.The purpose of the level is to check the verticality and horizontality of surfaces. The surfaces are rubbed clean with a float. Small sections of the wall and those adjacent to corners are processed with a float. You can apply the solution and level it with trowels. The rule is used when stretching the solution along the beacons (more on this later). The plaster mixture is collected, thrown, leveled and pressed with a trowel (float). The sokol is a plasterer's "palette" on which part of the solution is located, which allows the worker to avoid bending over to the container with it. The last tool on the list is a corner leveler. It is extremely useful when plastering corners. To use it, you need to put the solution in the corner. The leveler removes its excess and smooths the surface. The second layer is applied after the "splash" has dried. The solution thrown onto the wall is leveled with a float and a float. After hardening, the second layer is moistened and covered with a finishing layer of plaster. After application, it is rubbed with a float or trowel. Return to contents</a>Alignment with beacons Plastering the wall withsignificant irregularities are carried out after the installation of beacons. They are attached to the surface with plaster. And the alignment of the guides is carried out according to the sag - threads stretched on the wall, forming a plane. The sag is made simply:

After the plaster has hardened, you can applyplaster and level it with a rule resting on the beacons. After 24 hours, the beacons should be removed and the grooves filled with mortar. After they are leveled, a finishing layer of mortar is applied. Return to contents</a>

Compositions for decorative plastering

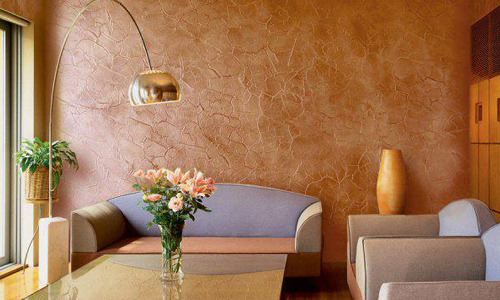

Figure 1.Venetian plaster can have a glossy or matte surface, similar to marble. At the very beginning, we already talked about the decorative qualities of wall plaster. Of course, it is not the usual cement-sand mixture that has them, but liquid wallpaper. They can be applied to the plastered surface after it has been treated with a primer. Liquid wallpaper can be used to decorate the wall using a sprayer, as well as in a more traditional way - a spatula. Then the liquid wallpaper is distributed more evenly with a roller. "Venetian" is also a decorative wall plaster. How surfaces decorated with it can look is shown in Fig. 1. This mixture can only be used on carefully leveled surfaces. The walls that you plastered using beacons fit this definition quite well. Now they just need to be primed twice. Venetian plaster itself is applied in several layers, which gives the surface a rather attractive texture. The first layer of "Venetian" is applied with random strokes with a spatula. The result is scattered spots of finishing. The second layer closes the gaps between the previously applied strokes. After 4 hours, the wall is polished with fine sandpaper, and then rubbed with a sponge soaked in a special wax mastic.

Figure 1.Venetian plaster can have a glossy or matte surface, similar to marble. At the very beginning, we already talked about the decorative qualities of wall plaster. Of course, it is not the usual cement-sand mixture that has them, but liquid wallpaper. They can be applied to the plastered surface after it has been treated with a primer. Liquid wallpaper can be used to decorate the wall using a sprayer, as well as in a more traditional way - a spatula. Then the liquid wallpaper is distributed more evenly with a roller. "Venetian" is also a decorative wall plaster. How surfaces decorated with it can look is shown in Fig. 1. This mixture can only be used on carefully leveled surfaces. The walls that you plastered using beacons fit this definition quite well. Now they just need to be primed twice. Venetian plaster itself is applied in several layers, which gives the surface a rather attractive texture. The first layer of "Venetian" is applied with random strokes with a spatula. The result is scattered spots of finishing. The second layer closes the gaps between the previously applied strokes. After 4 hours, the wall is polished with fine sandpaper, and then rubbed with a sponge soaked in a special wax mastic.