A plasterboard ceiling, built with your own hands in an apartment, has many advantages: The plasterboard ceiling structure can be of any shape.

The plasterboard ceiling structure can be of any shape.

How to do it? Follow the instructions provided. They are not exhaustive, but they allow you to determine the order of work and some of its subtleties.

Tools, materials, preparatory work

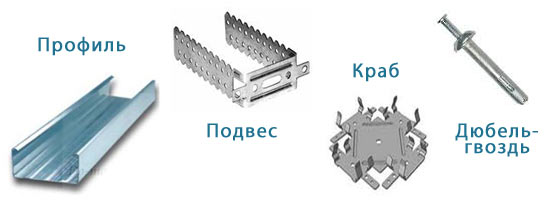

To make a plasterboard ceiling idealquality, it is necessary to prepare all the necessary materials and tools in advance. The plasterboard ceiling can be made of regular or waterproof material. The latter is more suitable for damp rooms: bathroom, sauna, etc. For the ceiling in the room, regular sheets with a thickness of 8-9.5 cm are recommended. In order not to be distracted during the work, all tools and accessories are prepared in advance. Elements for mounting the frame: metal profile, U-shaped strip hanger, crab for connecting profiles at right angles, dowel-nails.

Elements for mounting the frame: metal profile, U-shaped strip hanger, crab for connecting profiles at right angles, dowel-nails.

If additional insulation is plannedceiling, you will need heat-insulating material. In addition to tools, you will need a stepladder or, better yet, a long table on which you can move freely. All auxiliary materials can be of different quality and price. You should not buy the cheapest ones. If you do not understand the characteristics of primers, tapes, etc., it is better to choose well-known brands: world-famous manufacturers are usually responsible for their quality. Return to contents</a>

Beginning of work: marking and fixing the guides

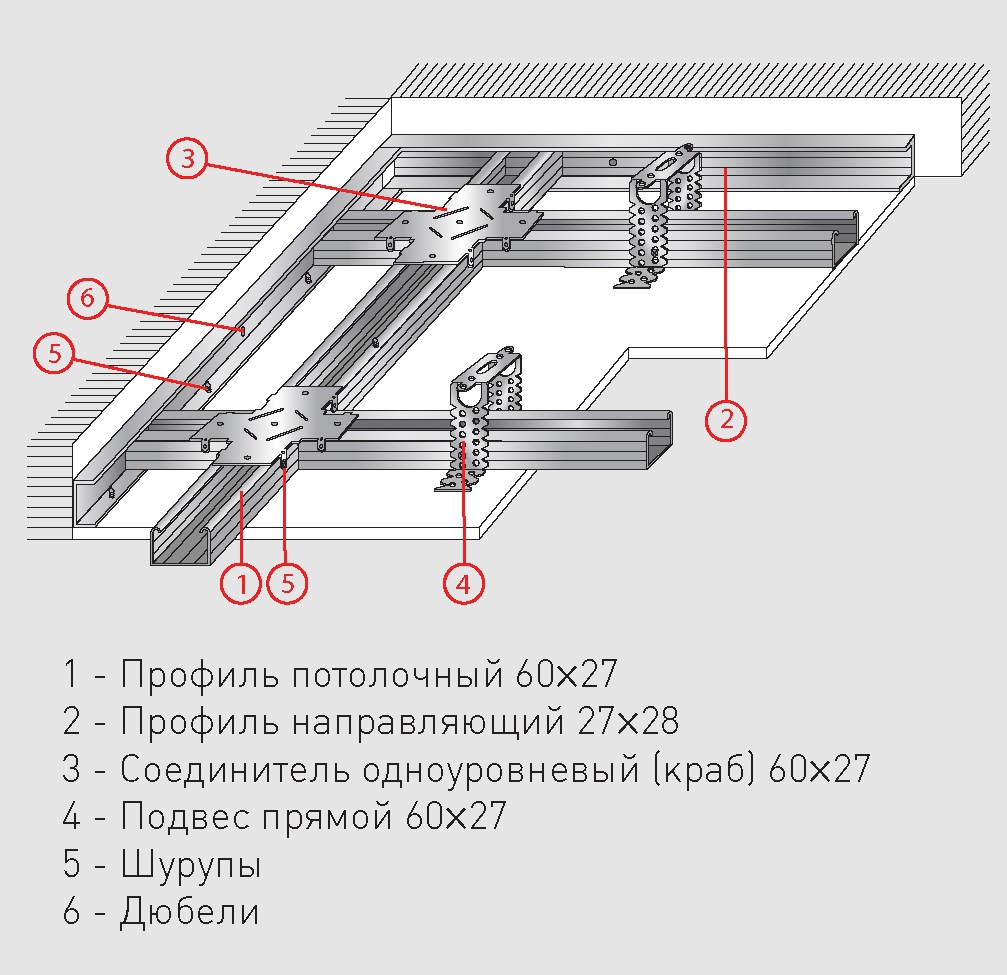

The marking of the plasterboard ceiling begins withthe lowest corner of the room. To find it, use a tape measure to measure the height of the walls in each corner, then use it to find the center of the ceiling. If you do not plan to mount lamps in the ceiling, then the first marks are placed at a distance of 5 cm from the wall. If there will be lamps, then at a distance of 8 cm. Then proceed as follows: Scheme of the plasterboard ceiling frame.

Scheme of the plasterboard ceiling frame.

The preparatory stage is over. It's time to install the frame for a single-level plasterboard ceiling. Return to contents</a>

Mounting the frame and conducting communications

The work begins with gluing the sealing tape to the hangers. Then everything is done in the following order: Possible profile installation schemes (for a 3x3 m room).

Possible profile installation schemes (for a 3x3 m room).

The frame assembly work is complete.Now it's time to lay the insulation and be sure to bring the planned communications under the ceiling. It is recommended to secure the wires (loosely) in the places of the planned exits. If this is not done, the ends of the wires may "go away" from the places of the intended fastenings. Return to the table of contents</a>

Fastening of plasterboard sheets

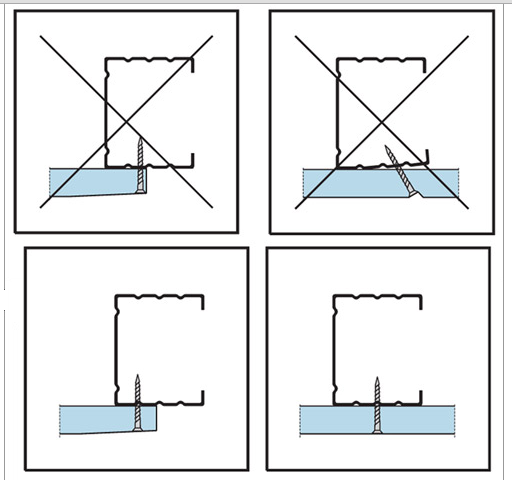

Drywall can be damaged due to temperature differencesslightly change their dimensions. Therefore, it should be placed in the room where it will be hung, 2-3 days before the start of installation. Important: to prevent the cardboard sheets from deforming, they are stored horizontally. The work algorithm is as follows: Correct and incorrect fastening of plasterboard sheets to the frame.

Correct and incorrect fastening of plasterboard sheets to the frame.

- Self-tapping screws should be placed 1.5 cm from the edges;

- the step between screws is 20 cm;

- the distance from the plasterboard sheets to the walls is 3 mm.

The sheets are fastened along the perimeter and in the center, ensuring thatso that their joints are staggered. The screw heads are sunk so that they do not protrude above the surface of the sheets. When all the sheets are secured, the seams are treated with a primer. After it dries, the seams near the wall are sealed with putty, then the screw heads, production seams, and joints between the sheets. The cardboard covering is not torn off. The dried putty is covered with serpyanka and putty again. You can put a "cobweb" on top: it will not only hide the remaining unevenness, but also give the ceiling strength. Then the ceiling is puttied and painted in the usual way.

A ceiling assembled according to this scheme will serve for many years without replacement.