Nowadays, when constructing buildings, it is veryAerated concrete is often used. It has low thermal conductivity and high strength, so it is used in the construction of single-story and multi-story buildings. Scheme of installation of walls from aerated concrete.Aerated concrete has a porous surface. It deteriorates from moisture and aggressive environmental influences, so walls made of aerated concrete blocks are covered with cladding. Puttying aerated concrete walls is part of these activities. Before doing it, it is necessary to carry out preparatory work.

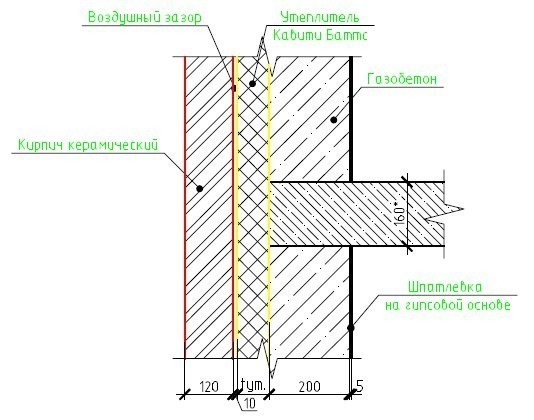

Scheme of installation of walls from aerated concrete.Aerated concrete has a porous surface. It deteriorates from moisture and aggressive environmental influences, so walls made of aerated concrete blocks are covered with cladding. Puttying aerated concrete walls is part of these activities. Before doing it, it is necessary to carry out preparatory work.

Aerated concrete as a material for the construction of buildings

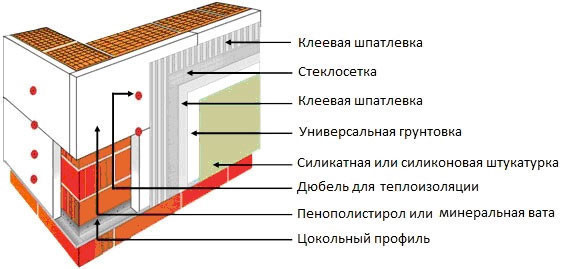

Gas blocks are made from cement, sand, lime,aluminum powder and water. Since water is used in the production of aerated concrete, the humidity of aerated concrete blocks is 30%. Therefore, after the completion of the construction of the house, six months must pass for the aerated concrete to dry and the foundation of the building to finally compact. Only then do they perform the cladding and puttying of the aerated concrete blocks. Scheme of the composition of a wall made of aerated concrete.When performing cladding work, the air temperature should be above 10 degrees Celsius, so the building is finished in spring or summer. Cladding is usually done to eliminate unevenness. When laying aerated concrete, the surface is quite smooth, deformations and joints are invisible. Therefore, when constructing buildings from aerated concrete, it is not necessary to do plastering. There are two types of finishing of aerated concrete walls: classic and lightweight. With classic finishing, plaster is applied, a mesh is laid, and then putty is applied. With the lightweight version, two layers of putty are applied. The most durable is the classic method of cladding. In this case, cracks and deformations do not occur. However, classic cladding requires more labor and has a higher cost. Lightweight finishing is simpler. If high-quality putty is used, then this type of finishing is quite durable. Return to contents</a>

Scheme of the composition of a wall made of aerated concrete.When performing cladding work, the air temperature should be above 10 degrees Celsius, so the building is finished in spring or summer. Cladding is usually done to eliminate unevenness. When laying aerated concrete, the surface is quite smooth, deformations and joints are invisible. Therefore, when constructing buildings from aerated concrete, it is not necessary to do plastering. There are two types of finishing of aerated concrete walls: classic and lightweight. With classic finishing, plaster is applied, a mesh is laid, and then putty is applied. With the lightweight version, two layers of putty are applied. The most durable is the classic method of cladding. In this case, cracks and deformations do not occur. However, classic cladding requires more labor and has a higher cost. Lightweight finishing is simpler. If high-quality putty is used, then this type of finishing is quite durable. Return to contents</a>

Classical cladding of aerocrete walls

Materials and tools: Wall puttying schemes.

Wall puttying schemes.

- putty;

- primer;

- solution tank;

- roller;

- putty knife;

- plastering mesh;

- beacon profiles;

- building rule;

- building level;

- plane;

- grater;

- drill.

First of all, you need to determine what is neededamount of materials for the job. Plaster is a layer that levels the surface and is the basis for subsequent cladding. Plaster is leveled while it is still wet. Putty is the top finishing layer, which is painted or wallpapered. Putty is leveled with a float after it dries. Gypsum plaster is used for living spaces. Cement plaster is used for the bathroom, which does not allow water to get on the walls. Before covering the walls with putty, you must first apply a primer, which will prevent the mixture from getting inside the aerated concrete blocks. First, the surface is thoroughly cleaned of dirt and dust. Unevenness is eliminated using a plane and a float. If any unevenness appears at the seams when laying aerated concrete blocks, they must be filled with a mixture for laying aerated concrete. Then, after the mixture dries, the surface is leveled with a float. After this, the horizontality is checked using a building level. House plastering scheme.Then the wall needs to be cleaned and primed. After the primer dries, the beacon profile needs to be fixed to the blocks. Then the plaster mixture is diluted in a special container. It is mixed with a drill. The plaster mixture is applied to the wall with a spatula. Then it is leveled until it is completely dry. After that, the plaster mesh is laid. It is pressed into the plaster layer. After that, you need to wait 24 hours for the plaster to dry. Then a primer is applied to the surface. After the primer dries, another plaster layer is applied at the level of the beacon profiles. The horizontality of the surface is checked using a building level and a straightedge. After applying the second plaster layer, you need to wait another day. Then the coating is primed and putty is applied. The putty should dry within 24 hours. Then it is leveled with a float. If the coating is not smooth enough, a top layer of putty is applied. Then the unevenness and deformations are rubbed down. Then the coating is primed again. Each new layer that is applied to the walls must be covered with a primer. After the last layer of primer has dried, the wall covering is ready. After this, you can stick wallpaper or paint the surface. Return to the table of contents</a>

House plastering scheme.Then the wall needs to be cleaned and primed. After the primer dries, the beacon profile needs to be fixed to the blocks. Then the plaster mixture is diluted in a special container. It is mixed with a drill. The plaster mixture is applied to the wall with a spatula. Then it is leveled until it is completely dry. After that, the plaster mesh is laid. It is pressed into the plaster layer. After that, you need to wait 24 hours for the plaster to dry. Then a primer is applied to the surface. After the primer dries, another plaster layer is applied at the level of the beacon profiles. The horizontality of the surface is checked using a building level and a straightedge. After applying the second plaster layer, you need to wait another day. Then the coating is primed and putty is applied. The putty should dry within 24 hours. Then it is leveled with a float. If the coating is not smooth enough, a top layer of putty is applied. Then the unevenness and deformations are rubbed down. Then the coating is primed again. Each new layer that is applied to the walls must be covered with a primer. After the last layer of primer has dried, the wall covering is ready. After this, you can stick wallpaper or paint the surface. Return to the table of contents</a>

Lightweight facing of walls made of aerated concrete

Tools for wall puttying. Materials and tools:

Tools for wall puttying. Materials and tools:

- putty for walls;

- primer;

- solution tank;

- roller;

- putty knife;

- building rule;

- building level;

- grater;

- sandpaper;

- drill.

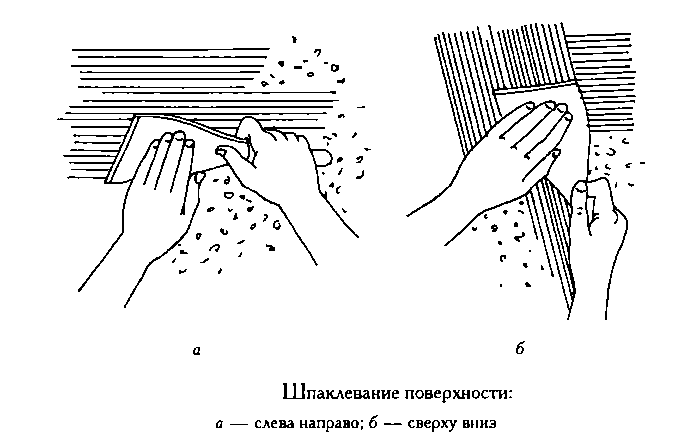

You can only apply putty to gas blocks.For this, it is better to use gypsum-based mixtures. The solution dries quickly, so the work must be done quickly. After the solution dries, the surface is processed with a float. Before puttying, a primer is applied to the wall. It is better to use a water-dispersed solution. After it dries, putty is applied. A day later, when the surface of the aerated concrete walls dries, it is leveled with a float. The putty is mixed in a clean bucket. First, water is poured in, then dry solution is poured in. Then the mixture is mixed with a drill until it becomes homogeneous. The solution should have the consistency of sour cream. A little putty is placed on a sheet and covered with polyethylene so that it does not dry out. Then, small portions of the solution are taken with a spatula and applied in a thin layer. When a certain area is covered with putty, it must be leveled. This is done with a spatula, with wide vertical or horizontal movements. The spatula is held at a slight angle. When the putty dries, it is processed with a float or sandpaper. Then a primer is applied. In some cases, two layers of putty are applied. For cladding the internal surfaces of aerated concrete blocks, lime or gypsum putty is used, as it provides good ventilation of aerated concrete. Work on applying putty to aerated concrete walls, carried out using this technology, will ensure the creation of a durable and reliable coating that will last for many years.</ ul>