Often when repairing a floor you have to resort toits alignment. This is due to the fact that before laying a new floor covering, you need to remove the old screed, since the base under it in the vast majority of cases cannot be called level. Floor repairs cannot be called complete if a new leveling screed is not laid on the floor. In order for the plane for subsequent finishing to be perfectly horizontal, you need to use tools and devices that will help to level the floor with the highest quality. All the tools for leveling the floor can be counted on the fingers, but working with them is quite painstaking and requires patience. Good repairs cannot be done without precise measurements and careful preparation of the base for subsequent finishing. For a complete floor repair, in most cases it is necessary to lay a new leveling screed on the ceiling.

For a complete floor repair, in most cases it is necessary to lay a new leveling screed on the ceiling.

Preparation for laying a new screed

A better leveling device has not yet been inventedlayer for floors than cement screed. On a properly poured screed, you can lay logs for installing wooden floors, install tiles, make self-leveling floors, etc. However, floor leveling does not begin with pouring it, but with the preparatory stage, at which the old layer of mortar is removed to the base, cracks in the ceiling are sealed, waterproofing is carried out and the surface is primed for laying a new coating. Return to the table of contents</a>Necessary tools and materials For the preparatory stage of floor repair, the following tools are required: Tools for the preparatory stage of laying the leveling screed.

Tools for the preparatory stage of laying the leveling screed.

- perforator;

- trowel or spatula;

- shovel;

- broom;

- scoop;

- Roller or brush for applying to the surface of impregnation.

You may need a vacuum cleaner to collect dust.and a building hair dryer for faster drying of accidental water spills. The materials needed to prepare the floor for leveling are as follows:

- cement-sand mixture;

- antifungal composition for impregnating the substrate;

- primer;

- polyethylene or roofing material for waterproofing.

Return to Contents</a>Sequence of work execution Scheme of leveling screed on beacons.The old layer of screed is removed with a hammer drill down to the main base. The mortar fragments and other debris are collected with a shovel, broom and dustpan. After sweeping or vacuuming the dust, it is necessary to wet clean the base, seal the cracks with cement mortar and leave the floor to dry. After the base dries, an impregnation is applied to it, and after some time, a primer composition is applied. When the primer dries, a waterproofing material is laid on the floor (in addition to polyethylene or roll materials, special polymer-based coatings can be used as a waterproofing material). The film or roofing felt should be laid with an overlap on the walls of the room, taking into account the height of the future screed. Adjacent insulator strips are laid with an overlap. The edges of the roofing felt are treated with bitumen mastic, and the edges of the polyethylene are glued with tape. Return to the table of contents</a>

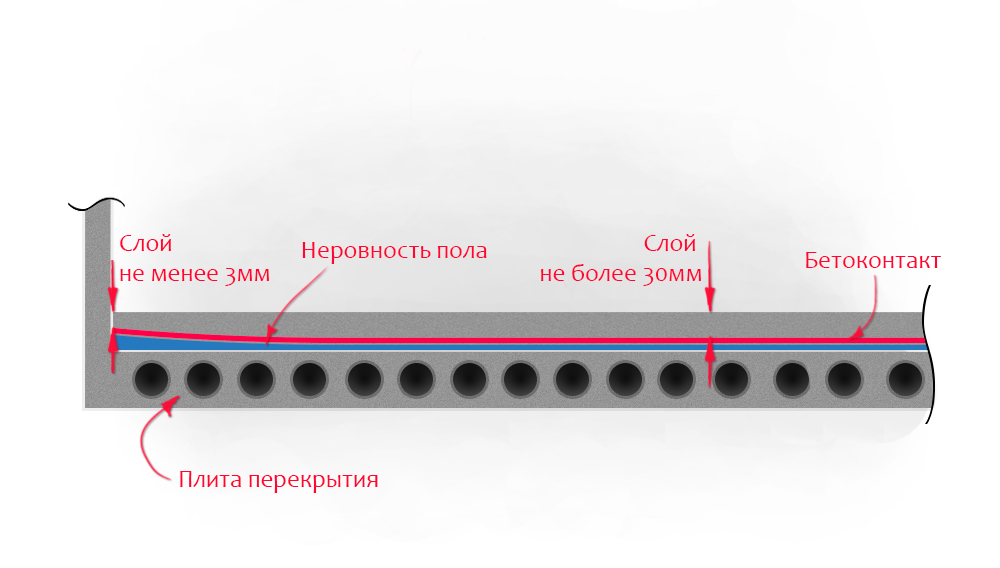

Scheme of leveling screed on beacons.The old layer of screed is removed with a hammer drill down to the main base. The mortar fragments and other debris are collected with a shovel, broom and dustpan. After sweeping or vacuuming the dust, it is necessary to wet clean the base, seal the cracks with cement mortar and leave the floor to dry. After the base dries, an impregnation is applied to it, and after some time, a primer composition is applied. When the primer dries, a waterproofing material is laid on the floor (in addition to polyethylene or roll materials, special polymer-based coatings can be used as a waterproofing material). The film or roofing felt should be laid with an overlap on the walls of the room, taking into account the height of the future screed. Adjacent insulator strips are laid with an overlap. The edges of the roofing felt are treated with bitumen mastic, and the edges of the polyethylene are glued with tape. Return to the table of contents</a>

Aligning the plane for a new leveling screed

Once you have laid down a securewaterproofing, you can start building a plane for leveling the floor. This work is quite painstaking, but does not present any particular difficulty. At this stage, the main tool for leveling the floors will be a painter's chalk line, with which the horizontal of the new screed will be determined along the perimeter of the room. Of course, one cord is not enough when constructing a plane. You will need:

- hydraulic level;

- a building ruler with a level and a tape measure;

- chalk and pencil;

- synthetic thread or line;

- beacon profile;

- dowels;

- self-tapping screws;

- gypsum or alabaster;

- Master OK;

- a hammer;

- drill and screwdriver.

First you need to be at some distance from the floorbeat off horizontal lines with chalk along all the walls of the room. This will be the so-called zero level. You can determine its height yourself. The horizontal can be beaten off at a distance of 20 centimeters from the floor, and at a height of 1.5 meters. Determining the plane for floor repair is carried out in the following order:

Now everything is ready for floor leveling. Return to contents</a>

Filling the leveling screed

It is highly desirable that the screed is poured in oneroom was done in one go. Then it will not be threatened by another repair due to the formation of a crack between the slabs poured at different times. In addition, the preparation of cement-sand mortar in all batches should be carried out in the same proportions of each component of the leveling mixture. This will ensure uniformity of the base in density, which will have a positive effect on the monolithicity of the leveling coating. The work should be carried out at an optimal air temperature for the installation of the screed - from +15 to +25 °. Leveling the floor with cement mortar is carried out using a rule - an aluminum or wooden beam with a trapezoidal cross-section. Scheme of a self-leveling floor.This tool is necessary for floor repair. Today it is freely sold in any hardware store. The solution is laid out between the beacons. Its pouring should begin from the wall farthest from the door to the room. The rule, which is carried out along two adjacent beacons, evenly distributes the mixture over the surface. Do not try to immediately pour the tape between the beacons from the far wall to the door. Fill the space between the profiles with the solution gradually. Having finished leveling on the site at the wall opposite the entrance, rub the screed with a plaster float. After this, continue pouring on the next patch, 20-30 minutes after it, do its grouting and continue the process further. Return to the table of contents</a>

Scheme of a self-leveling floor.This tool is necessary for floor repair. Today it is freely sold in any hardware store. The solution is laid out between the beacons. Its pouring should begin from the wall farthest from the door to the room. The rule, which is carried out along two adjacent beacons, evenly distributes the mixture over the surface. Do not try to immediately pour the tape between the beacons from the far wall to the door. Fill the space between the profiles with the solution gradually. Having finished leveling on the site at the wall opposite the entrance, rub the screed with a plaster float. After this, continue pouring on the next patch, 20-30 minutes after it, do its grouting and continue the process further. Return to the table of contents</a>

Completing the alignment

Floor repairs do not end immediately aftercompletion of the screed pouring. It needs to be moistened with water for another 3-4 days so that the solution hardening process is more uniform. 2-3 days after leveling, the beacons are removed from the screed, and the resulting grooves are treated with a primer for better adhesion and sealed with a solution. The surface is covered with polyethylene for a week. After 7 days, the coating is removed, but the complete hardening of the solution will be completed in another 2 weeks. After this, you can begin finishing the floor with a finishing coating.</ ul>