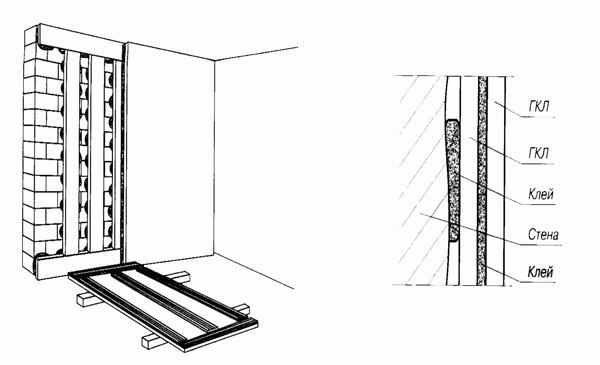

Modern construction and renovation are unthinkable withoutusing plasterboards in interior decoration. They are used not only to level walls and ceilings, but also to install partitions, cornices, niches and multi-level ceilings. This finishing material is very flexible and easy to work with. It is easy to cut, creating even curvilinear shapes. Plasterboard wall diagram.The use of plasterboard has made repairs much cheaper and better. Self-installation of plasterboard on the wall requires certain knowledge and compliance with some simple rules.

Plasterboard wall diagram.The use of plasterboard has made repairs much cheaper and better. Self-installation of plasterboard on the wall requires certain knowledge and compliance with some simple rules.

Types and dimensions of gypsum boards

Drywall is a finishing material,having the appearance of a rectangular plate consisting of two layers of multilayer paper and a gypsum mineral layer between them. The paper protects the gypsum from destruction and also holds the internal stress of the material within the layers, which allows the sheet to be used in finishing works. According to its purpose, gypsum board is divided into regular, moisture-resistant and fire-resistant. The sheets have standard sizes: length 2.5 or 3 meters, width 1.2 meters, thickness 6 mm, 9 mm, 12.5 mm. Sometimes you can find sheets with dimensions of 1200X600X12.5 mm. It should be understood that a sheet thickness of 12.5 mm is allowed. Thinner types of sheets are intended for other purposes. This is the manufacture of curved and bent surfaces. Return to contents</a>

The main technological methods for fixing gypsum board slabs

There are several ways to securely attach plasterboard sheets to walls: Correct and incorrect fastening of plasterboard sheets to the frame.

Correct and incorrect fastening of plasterboard sheets to the frame.

In any of the methods, it is necessary to take into account in advance the features of the installation of electrical wiring and the location of electrical appliances in the room. Return to the table of contents</a>

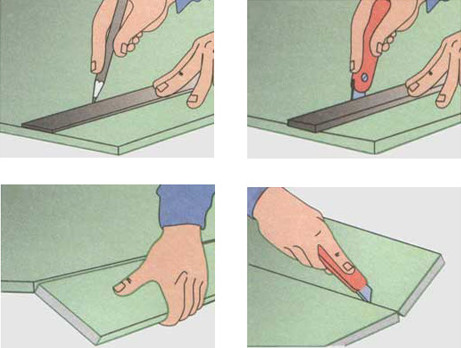

Rules for cutting gypsum board parts

Scheme of cutting drywall using a knife.To cut drywall, you will only need a paper knife, a ruler and a pencil. To sand the edges of the cut, you can effectively use an auxiliary tool: a special plane, a grater with sandpaper attached to it, or a large file. Before cutting off a part of the sheet, you need to mark it out according to size using a ruler and a pencil. Then make a cut in the paper layer with a knife on one side. After that, you need to bend the drywall sheet at an angle of 90 degrees towards the cut and cut the paper on the opposite side. The cut will be quite even. Now you need to remove the chamfer from it. To do this, cut off the paper layers on both sides of the sheet at a distance of 1 cm from the edge of the cut. This is done to avoid tearing the paper. Now we remove the chamfer from the edge with a knife at an angle of 45 degrees. The irregularities are cleaned up using an auxiliary tool. Return to the table of contents</a>

Scheme of cutting drywall using a knife.To cut drywall, you will only need a paper knife, a ruler and a pencil. To sand the edges of the cut, you can effectively use an auxiliary tool: a special plane, a grater with sandpaper attached to it, or a large file. Before cutting off a part of the sheet, you need to mark it out according to size using a ruler and a pencil. Then make a cut in the paper layer with a knife on one side. After that, you need to bend the drywall sheet at an angle of 90 degrees towards the cut and cut the paper on the opposite side. The cut will be quite even. Now you need to remove the chamfer from it. To do this, cut off the paper layers on both sides of the sheet at a distance of 1 cm from the edge of the cut. This is done to avoid tearing the paper. Now we remove the chamfer from the edge with a knife at an angle of 45 degrees. The irregularities are cleaned up using an auxiliary tool. Return to the table of contents</a>

The order of gypsum wall construction

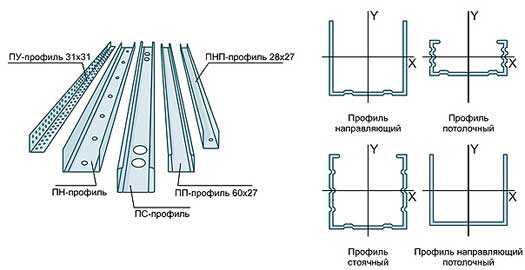

Before you start installing drywall onwalls, some preparatory work should be done. It is necessary to carry out preliminary installation of electrical wiring. To do this, we fix the wires in corrugated protective tubes to the walls and mark the places where sockets, switches and distribution boxes exit to the surface. It is necessary to immediately pull the horizontal wires at the level of the distribution boxes, and the vertical ones exactly up from the switches and sockets. It is forbidden to place the wires inside the metal profile, since self-tapping screws will be screwed into it. Return to the table of contents</a>Installation of a frame made of metal profile Profiles for plasterboard. Before installing the frame, the walls are marked. For this, you will need the following construction tools:

Profiles for plasterboard. Before installing the frame, the walls are marked. For this, you will need the following construction tools:

With their help it is measured and fixed on the walllocation of all elements of the future frame. All angles must be right angles, and the elements must be strictly vertical and horizontal. It is necessary that before installing drywall on the walls it is known where hanging furniture or other interior items will be attached. This will allow you to strengthen such places for further use. The marking of vertical and horizontal elements of the frame is made taking into account the dimensions of the foxes. In the future, this will make it more convenient to install drywall. Then, strictly according to the marking, a frame made of metal profile is installed. For its installation, you will need the following tool:

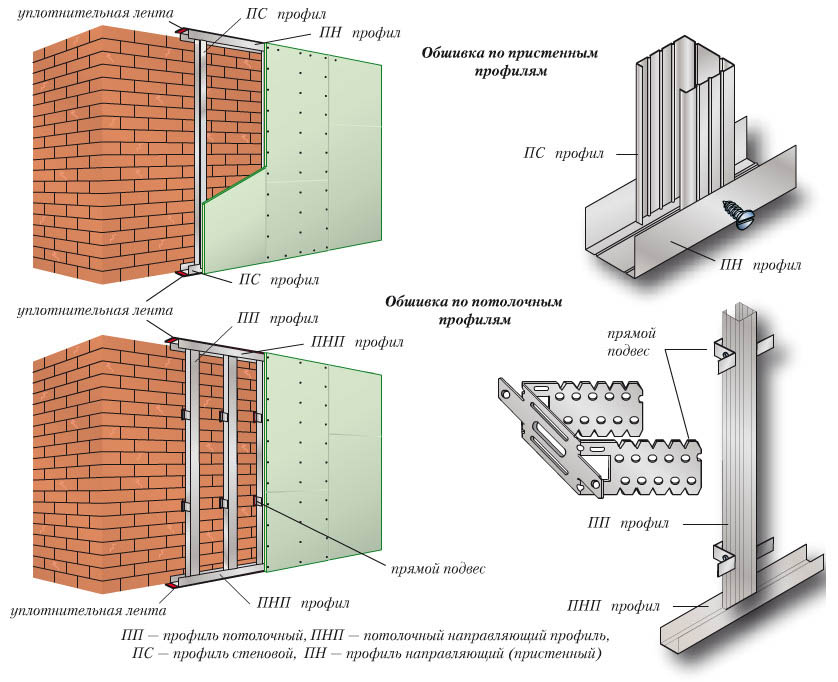

Scheme of wall covering with plasterboard onmetal frame. The metal profile is cut into sections of the required length, which are connected to each other using a T-shaped connection or with special cross-shaped "crabs". Self-tapping screws are used. This structure is attached to the walls using U-shaped construction hangers. Each of them must be securely fastened to the wall with two self-tapping screws. In this case, it is necessary to strictly observe the level of the surface to which the sheets of drywall will be attached. To do this, strings are pulled between the first and last vertical guides, which are set with the required gap from the wall. All other guides should touch the strings, but not move them away. The frame for drywall must be stable and durable. Return to contents</a>Fastening and processing of plasterboard sheetsAfter the frame installation is complete and it has been tested for strength, you can begin finishing the wall with your own hands. The prepared sheets of plasterboard are attached with screws to the frame guides strictly vertically. In this case, the sheets are raised from the floor by several millimeters, which is necessary to avoid their further deformation during operation due to shrinkage. All boxes for sockets and switches are attached to the sheets, and the wires are brought out. The resulting joints and corners are subject to mandatory processing. This will require the following additional tools:

Scheme of wall covering with plasterboard onmetal frame. The metal profile is cut into sections of the required length, which are connected to each other using a T-shaped connection or with special cross-shaped "crabs". Self-tapping screws are used. This structure is attached to the walls using U-shaped construction hangers. Each of them must be securely fastened to the wall with two self-tapping screws. In this case, it is necessary to strictly observe the level of the surface to which the sheets of drywall will be attached. To do this, strings are pulled between the first and last vertical guides, which are set with the required gap from the wall. All other guides should touch the strings, but not move them away. The frame for drywall must be stable and durable. Return to contents</a>Fastening and processing of plasterboard sheetsAfter the frame installation is complete and it has been tested for strength, you can begin finishing the wall with your own hands. The prepared sheets of plasterboard are attached with screws to the frame guides strictly vertically. In this case, the sheets are raised from the floor by several millimeters, which is necessary to avoid their further deformation during operation due to shrinkage. All boxes for sockets and switches are attached to the sheets, and the wires are brought out. The resulting joints and corners are subject to mandatory processing. This will require the following additional tools:

A thin layer of putty is applied to the seams, anda construction mesh is glued to it. Then the next layer of putty is applied over the mesh. The seams on the entire surface of the walls are leveled with a spatula. The internal corners are coated with putty and leveled. The external corners require more attention. A metal or plastic corner is glued to them, which protects the corner from cracks. The plastic corner can also be glued over the wallpaper. When finishing, special attention should be paid to walls with window or door openings. Already at the marking stage, it is necessary to provide for all the nuances of fastening the frame guides. Return to the table of contents</a>

Arrangement of interior partitions

You can make not only walls fromplasterboard, but also partitions - for this, a frame is constructed from a metal profile, which is rigidly attached to the floor and ceiling. The principle of its installation is similar to the one described above. Then, plasterboard is installed on this frame according to the same rules. Installing plasterboard on walls with your own hands should only be done on a reliable frame that has a perfect fastening. Thus, in order to make plasterboard walls with your own hands, you need to prepare all the necessary tools and get to work, observing all the rules.