There is a popular saying:"Repairs cannot be finished, they can be temporarily suspended." Agree that this is said about you and me. We are constantly looking for something, experimenting, doing and redoing. Scheme of installation of sockets in open wiring circuits.After all, you want to create an atmosphere of comfort and warmth around you. And we often do all this from environmentally friendly materials. Here, plasterboard can safely be considered the most reliable. And it is not difficult to work with it, and everything turns out very beautiful and modern. But when installing sockets on plasterboard partitions, roughness periodically occurs. To avoid certain problems when installing sockets and switches on plasterboard, we will reveal some tricks that are used by finishing masters.

Scheme of installation of sockets in open wiring circuits.After all, you want to create an atmosphere of comfort and warmth around you. And we often do all this from environmentally friendly materials. Here, plasterboard can safely be considered the most reliable. And it is not difficult to work with it, and everything turns out very beautiful and modern. But when installing sockets on plasterboard partitions, roughness periodically occurs. To avoid certain problems when installing sockets and switches on plasterboard, we will reveal some tricks that are used by finishing masters.

How is the wall prepared and assembled?

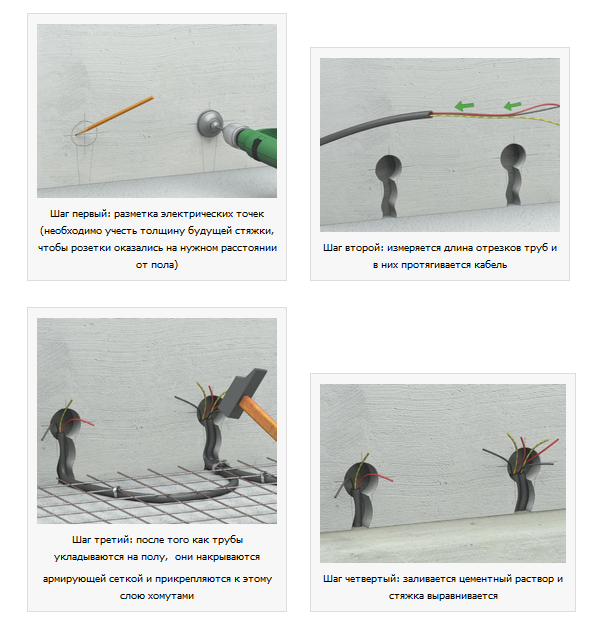

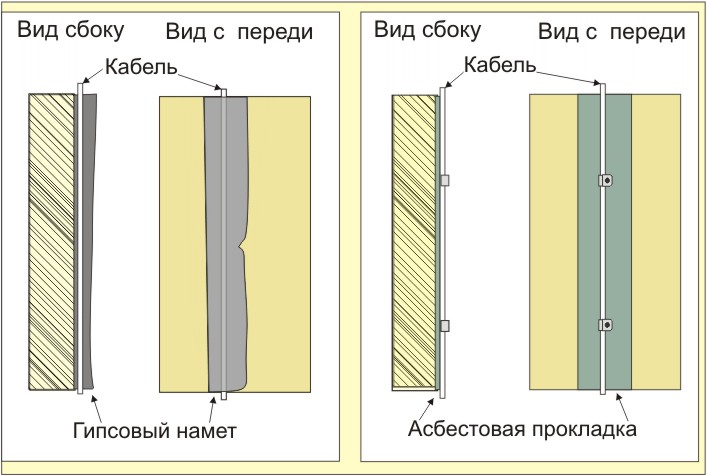

Scheme of wall preparation for installationsockets. Before installing a wall made of plasterboard sheets, it is necessary to think over the location of the electrical system in the room and purchase the required amount of electrical cable, a protective casing for it and the corresponding number of switches and sockets. You need to start installing the electrical system when assembling the frame for the plasterboard. Holes are made in the profiles through which a corrugated protective casing with an electrical cable located inside is passed. It is necessary to try to ensure that when laying the cable, right angles are observed when turning. This may not be very economical, but at least you will approximately know the location of the cable inside the wall and will not damage it during subsequent repairs or reconstruction. Return to contents</a>

Scheme of wall preparation for installationsockets. Before installing a wall made of plasterboard sheets, it is necessary to think over the location of the electrical system in the room and purchase the required amount of electrical cable, a protective casing for it and the corresponding number of switches and sockets. You need to start installing the electrical system when assembling the frame for the plasterboard. Holes are made in the profiles through which a corrugated protective casing with an electrical cable located inside is passed. It is necessary to try to ensure that when laying the cable, right angles are observed when turning. This may not be very economical, but at least you will approximately know the location of the cable inside the wall and will not damage it during subsequent repairs or reconstruction. Return to contents</a>

What tools will be required?

Scheme for installing a socket box on drywall.Now you have to finally assemble the wall from plasterboard, marking the places where the wires end. According to European standards, sockets should be at a height of about 30 cm, and switches - about 90 cm from the floor. With this calculation, the wiring is laid in the frame. We mark the output places on the sheets of plasterboard with a cross and prepare the tools for installing the sockets. Namely:

Scheme for installing a socket box on drywall.Now you have to finally assemble the wall from plasterboard, marking the places where the wires end. According to European standards, sockets should be at a height of about 30 cm, and switches - about 90 cm from the floor. With this calculation, the wiring is laid in the frame. We mark the output places on the sheets of plasterboard with a cross and prepare the tools for installing the sockets. Namely:

- screwdriver or drill;

- knife;

- screwdriver;

- milling cutter;

- screwdriver-indicator;

- Nippers;

- itself outlet.

Nozzle for making holes for sockets andswitches among users are called "ballerina". This is a regular drill with a cutter in the form of a skirt. Before starting work, you need to make sure that the cutter is installed correctly and has no play when rotating. Incorrect installation will lead to the edges of the holes being uneven. This will make it difficult to install the socket on the drywall. Do not forget to turn off the electricity in the part of the house where you are installing. And now you can proceed to the main type of work. Return to the table of contents</a>

How is the phased installation of the sockets?

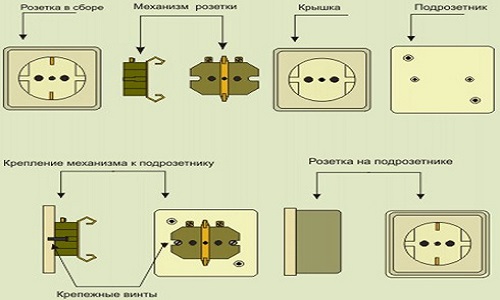

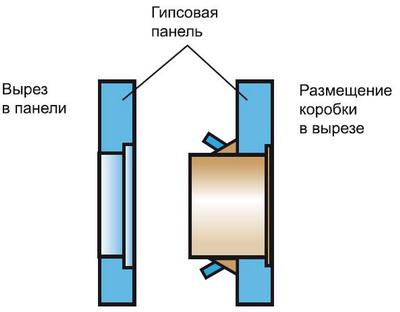

Check first if yours are locatedmarks for sockets on one horizontal line. If this condition is met, then you can start drilling holes and then it will be easier to install the socket in the drywall. There is no need to apply great efforts: drywall is a very fragile material, so additional impacts on it are unnecessary. The "Ballerina" will do the job perfectly, you just need to give it the right direction and maintain it until the end of drilling. Your muscle memory will work more, since when drilling drywall, a large amount of dust is released, which makes visual control very difficult. Sockets for drywall do not have certain differences from ordinary sockets, except that they are equipped with a special "cup" - a socket box. Electrical wiring diagram for plasterboard.As a rule, the dimensions of the wall box exactly match the dimensions of the drywall profiles, taking into account the thickness of the material itself. This factor cannot be ignored: it is better if the wall box fits tightly to the wall with its lower part. This way, it can be additionally secured, which will increase its stability. It is worse if the wall box protrudes slightly above the drywall level when installed in the partition. You will have to remake the product to fit the existing parameters of the partition. Fortunately, wall boxes are made of materials that can be easily cut. As mentioned above, the outer casing should fit tightly to the drywall wall, and this is what you should strive for. Let's assume that the wall box fits perfectly into the existing parameters of the wall. It is not worth fixing it yet. First, you need to make holes in the wall box body and bring the ends of the wiring (not the casing) there. A small "reserve" of wiring will not hurt. Now you can secure the wall box with two special screws located at the corners and start connecting the socket itself. Again, there are absolutely no differences here: release the clamping screws on the socket body, expose the ends of the wires (about 1 cm), insert them into the holes and tighten the screws until they stop. All that remains is to check the reliability of the connection. If everything works out well, then install the socket body in the wall box and fasten these elements with two screws. After that, you can screw on the outer panel of the socket. Return to the table of contents</a>

Electrical wiring diagram for plasterboard.As a rule, the dimensions of the wall box exactly match the dimensions of the drywall profiles, taking into account the thickness of the material itself. This factor cannot be ignored: it is better if the wall box fits tightly to the wall with its lower part. This way, it can be additionally secured, which will increase its stability. It is worse if the wall box protrudes slightly above the drywall level when installed in the partition. You will have to remake the product to fit the existing parameters of the partition. Fortunately, wall boxes are made of materials that can be easily cut. As mentioned above, the outer casing should fit tightly to the drywall wall, and this is what you should strive for. Let's assume that the wall box fits perfectly into the existing parameters of the wall. It is not worth fixing it yet. First, you need to make holes in the wall box body and bring the ends of the wiring (not the casing) there. A small "reserve" of wiring will not hurt. Now you can secure the wall box with two special screws located at the corners and start connecting the socket itself. Again, there are absolutely no differences here: release the clamping screws on the socket body, expose the ends of the wires (about 1 cm), insert them into the holes and tighten the screws until they stop. All that remains is to check the reliability of the connection. If everything works out well, then install the socket body in the wall box and fasten these elements with two screws. After that, you can screw on the outer panel of the socket. Return to the table of contents</a>

What else can I advise to simplify the installation of the outlet?

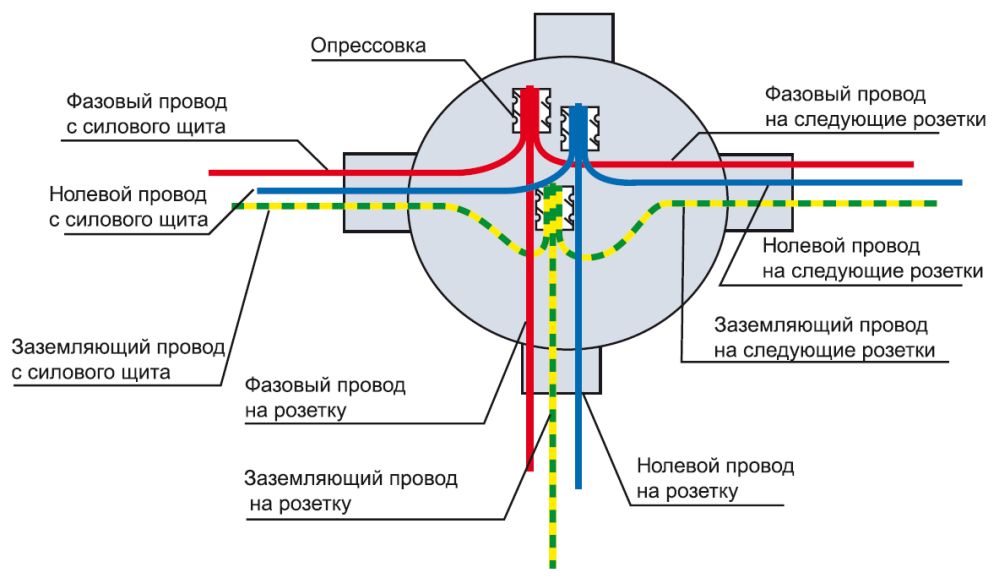

Wiring diagram in the distributionbox for one socket. As you have already noticed, sockets for plasterboard are no different from ordinary ones both in appearance and in the method of installation. It is unusual only to install the socket for the first time. But even in this case, you can do it in about 10 minutes. In the future, the time for installing a socket under plasterboard will be significantly reduced. Earlier, the recommended level of installation of a socket or switch according to European standards was mentioned. Recommended - this does not mean mandatory. Everyone can do it as they like. This is especially true for the kitchen. Agree that here the sockets should be located so that the hostess of the kitchen does not have to constantly reach for them. Make the sockets as convenient as possible. Note that modern kitchens are very saturated with electrical appliances, accordingly, the load on the electrical wiring here is huge. Make sure that the electrical cables for the kitchen are rated for high power and have good insulation even before installing the socket. The sockets themselves under the plasterboard for the kitchen must be grounded. If you cannot calculate all the parameters yourself, then you should consult an experienced electrician.

Wiring diagram in the distributionbox for one socket. As you have already noticed, sockets for plasterboard are no different from ordinary ones both in appearance and in the method of installation. It is unusual only to install the socket for the first time. But even in this case, you can do it in about 10 minutes. In the future, the time for installing a socket under plasterboard will be significantly reduced. Earlier, the recommended level of installation of a socket or switch according to European standards was mentioned. Recommended - this does not mean mandatory. Everyone can do it as they like. This is especially true for the kitchen. Agree that here the sockets should be located so that the hostess of the kitchen does not have to constantly reach for them. Make the sockets as convenient as possible. Note that modern kitchens are very saturated with electrical appliances, accordingly, the load on the electrical wiring here is huge. Make sure that the electrical cables for the kitchen are rated for high power and have good insulation even before installing the socket. The sockets themselves under the plasterboard for the kitchen must be grounded. If you cannot calculate all the parameters yourself, then you should consult an experienced electrician.