The stepladder chair is made of different materials.  Having at hand only all the necessary tools andplywood, you can make a stepladder with your own hands. To make a wooden structure, you need a bar, plywood, a hacksaw, a jigsaw, drills, a grinder, a spatula.

Having at hand only all the necessary tools andplywood, you can make a stepladder with your own hands. To make a wooden structure, you need a bar, plywood, a hacksaw, a jigsaw, drills, a grinder, a spatula.

Making a stool

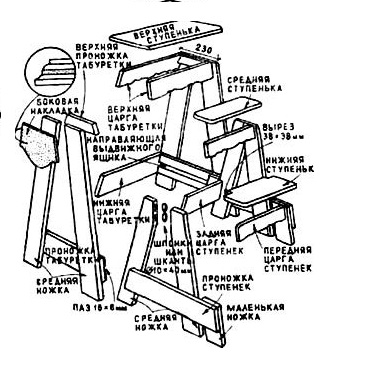

A drawing is prepared in advance forwhich denotes the constituent elements of the product and its parameters. The stepladder consists of racks, a seat, a support post, a ladder march. When you make an independent stool, the following parameters are taken into account:

- seat height - 60 cm;

- between the support and the string must be a distance of 60 cm;

- between the strings of the ladder, a distance of 48 cm is observed.

Scheme of stool-ladders. The stepladder chair, made by your own hands, will be comfortable to use if you place the steps in steps of 15-20 cm. To make a seat, you will need cross strips. Preliminary wood is processed (to obtain a perfectly smooth surface). Reiki are fixed with each other. From the edge from 2 sides an indentation of 5 cm is made. To make a groove, you need a router. Then the cross bars are fixed on the rail-bases. To increase the strength of the product, glue is used. You can make the seats themselves from 2 boards in the size of 150x500 mm. The supporting part of the structure is made of guide rails, which are designed to provide connection (horizontally) and increase the strength of furniture. At the ends of the wood holes are drilled. As the staircase march is fixed at an angle, the stairs of the staircase are mounted horizontally. To determine the angle, it is recommended to assemble furniture without steps and connecting bars. Elements of the construction are set taking into account the above recommendations. Then the product is fixed. The lower ends of the string and supports are cut at an appropriate angle. The next step is to mark the position of the steps. The width of the 1st stage should be 44 cm, and the depth - 15 cm. To collect the stairs, a ladder will need a string. Guide posts are attached to the seat. The upper ends of each rail are rounded. The resulting furniture is varnished. Back to contents</a>

Scheme of stool-ladders. The stepladder chair, made by your own hands, will be comfortable to use if you place the steps in steps of 15-20 cm. To make a seat, you will need cross strips. Preliminary wood is processed (to obtain a perfectly smooth surface). Reiki are fixed with each other. From the edge from 2 sides an indentation of 5 cm is made. To make a groove, you need a router. Then the cross bars are fixed on the rail-bases. To increase the strength of the product, glue is used. You can make the seats themselves from 2 boards in the size of 150x500 mm. The supporting part of the structure is made of guide rails, which are designed to provide connection (horizontally) and increase the strength of furniture. At the ends of the wood holes are drilled. As the staircase march is fixed at an angle, the stairs of the staircase are mounted horizontally. To determine the angle, it is recommended to assemble furniture without steps and connecting bars. Elements of the construction are set taking into account the above recommendations. Then the product is fixed. The lower ends of the string and supports are cut at an appropriate angle. The next step is to mark the position of the steps. The width of the 1st stage should be 44 cm, and the depth - 15 cm. To collect the stairs, a ladder will need a string. Guide posts are attached to the seat. The upper ends of each rail are rounded. The resulting furniture is varnished. Back to contents</a>

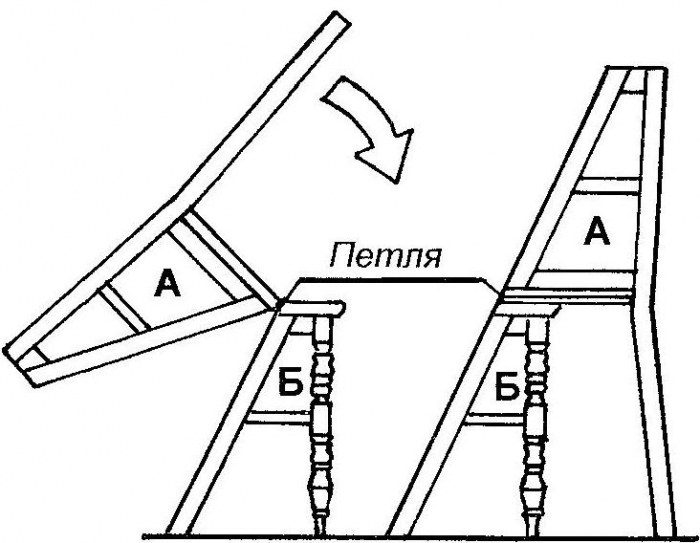

Folding structure

To make a folding chair, stepladder,it will be necessary to make figured elements. The edges of the components of the furniture are treated with sandpaper. To connect the mobile and fixed parts, use piano loops. The construction of a stool with a movable module provides for the production of 2 steps.  Scheme of the transformation of the chair into the stepladder. The module extends due to the guides. The chair-ladder is presented in the form of 4 legs, footboards and a king. The thickness of each part is 19 mm. Side panels are made of plywood with a thickness of 3 mm and parameters of 17x25 cm. To make a staircase, you will need guides 31 cm long, fasteners, lacquer, glue, drill. Legs, lining and footsteps cut out of blanks. The upper ends of the king should be cut at an angle of 80 degrees. The steps are sawed. Their ribs are rounded. At the bottom step, do notched corners are 3.8 x 3.8 cm in size. For the assembly of furniture, screws and dowels are used. The upper and lower kargas are fastened. The middle legs are assembled in pairs. The knots are connected by the kings. Screws are used to fix small legs. The supports are attached to the thimbles and connected by the king. Then, the remaining 2 steps are strengthened. The obtained parts of the chair are set as they will be fixed. Free elements of the guides are fixed. If the assembly is done correctly, then the stool is disassembled. Installation of the stair-ladder is made anew with the help of joinery glue. The finished structure is covered with putty and varnish. Plywood pads can be painted. Metal chairs-ladders are equipped with 2-3 steps. Such furniture can be with one-sided or two-sided climbing. The metal structure has the following advantages:

Scheme of the transformation of the chair into the stepladder. The module extends due to the guides. The chair-ladder is presented in the form of 4 legs, footboards and a king. The thickness of each part is 19 mm. Side panels are made of plywood with a thickness of 3 mm and parameters of 17x25 cm. To make a staircase, you will need guides 31 cm long, fasteners, lacquer, glue, drill. Legs, lining and footsteps cut out of blanks. The upper ends of the king should be cut at an angle of 80 degrees. The steps are sawed. Their ribs are rounded. At the bottom step, do notched corners are 3.8 x 3.8 cm in size. For the assembly of furniture, screws and dowels are used. The upper and lower kargas are fastened. The middle legs are assembled in pairs. The knots are connected by the kings. Screws are used to fix small legs. The supports are attached to the thimbles and connected by the king. Then, the remaining 2 steps are strengthened. The obtained parts of the chair are set as they will be fixed. Free elements of the guides are fixed. If the assembly is done correctly, then the stool is disassembled. Installation of the stair-ladder is made anew with the help of joinery glue. The finished structure is covered with putty and varnish. Plywood pads can be painted. Metal chairs-ladders are equipped with 2-3 steps. Such furniture can be with one-sided or two-sided climbing. The metal structure has the following advantages:

- low weight;

- strength;

- speed of assembly;

- Comfortable application due to the presence of rubber overlays on the steps;

- availability of a broad platform;

- stability.

Elements of a metal staircasefixed with standard bolts. If necessary, they can be replaced by new analogues. Unlike a wooden structure, a metal step-ladder can be stored in basements and other damp premises.