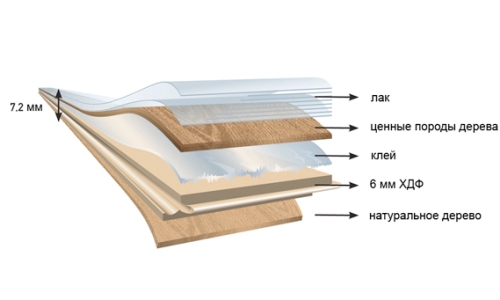

Choosing a floor covering is not easytask, since it is necessary to take into account both the characteristics of the material and the characteristics of the room in which the repair is being carried out. You should approach the purchase responsibly, since in case of an incorrect choice you will have to dismantle the floor, which is not only troublesome, but also very expensive. Scheme of the parquet board structure.The leader among modern floor coverings is parquet board, made of natural wood and giving the interior a special chic. The assortment becomes more extensive every season, which makes it necessary to solve a difficult question: which parquet board to buy? In order to choose the ideal covering, it is necessary to pay attention to the following parameters during the purchase process: size, selection of planks, type of wood, number of strips, type of final processing.

Scheme of the parquet board structure.The leader among modern floor coverings is parquet board, made of natural wood and giving the interior a special chic. The assortment becomes more extensive every season, which makes it necessary to solve a difficult question: which parquet board to buy? In order to choose the ideal covering, it is necessary to pay attention to the following parameters during the purchase process: size, selection of planks, type of wood, number of strips, type of final processing.

How to choose a parquet board in size?

The first thing you need to pay attention to when choosing a floor covering is its dimensions. Parquet boards are available in the following sizes:

- thickness from 7 to 26 mm;

- width up to 20 cm;

- the length is 200-250 cm.

“Pie” of parquet board.The optimal length and width are selected depending on the area and architectural features of the room. Preference should be given to the option that will minimize the amount of waste. The choice of optimal thickness depends on how strong the load on the floor will be. A board 7-10 mm thick has a thin top layer, so with frequent and aggressive mechanical impact, abrasions quickly appear. For residential premises, it is necessary to choose a coating 13-15 mm thick, which is more resistant to abrasion and can be sanded. In public places, where the floor regularly experiences high loads, it is worth using a coating of 20-25 mm. Return to contents</a>

“Pie” of parquet board.The optimal length and width are selected depending on the area and architectural features of the room. Preference should be given to the option that will minimize the amount of waste. The choice of optimal thickness depends on how strong the load on the floor will be. A board 7-10 mm thick has a thin top layer, so with frequent and aggressive mechanical impact, abrasions quickly appear. For residential premises, it is necessary to choose a coating 13-15 mm thick, which is more resistant to abrasion and can be sanded. In public places, where the floor regularly experiences high loads, it is worth using a coating of 20-25 mm. Return to contents</a>

Types of selection of planks of a parquet board

Selection of planks is the process of selection andsorting of wood used for the top layer of parquet boards. The decorative characteristics and durability of the coating depend on the quality of the top layer. The bottom two layers are standard and are made of coniferous wood. In the process of selecting planks, the type of sawing of the trunk, the pattern and color, and any defects are taken into account. The following types of selection are distinguished: Technology of laying parquet boards.

Technology of laying parquet boards.

Planks made of radial timbersawing, are more resistant to moisture and mechanical impacts. From the wood of the Select and Natur selections, a beautiful uniform coating is obtained, so it is worth choosing parquet boards of these types for expensive offices and interiors in a classic style. Planks of the Rustic selection are often used as an unusual design solution, making the interior brighter and more lively. Return to the table of contents</a>

What kind of wood can a parquet board be made from?

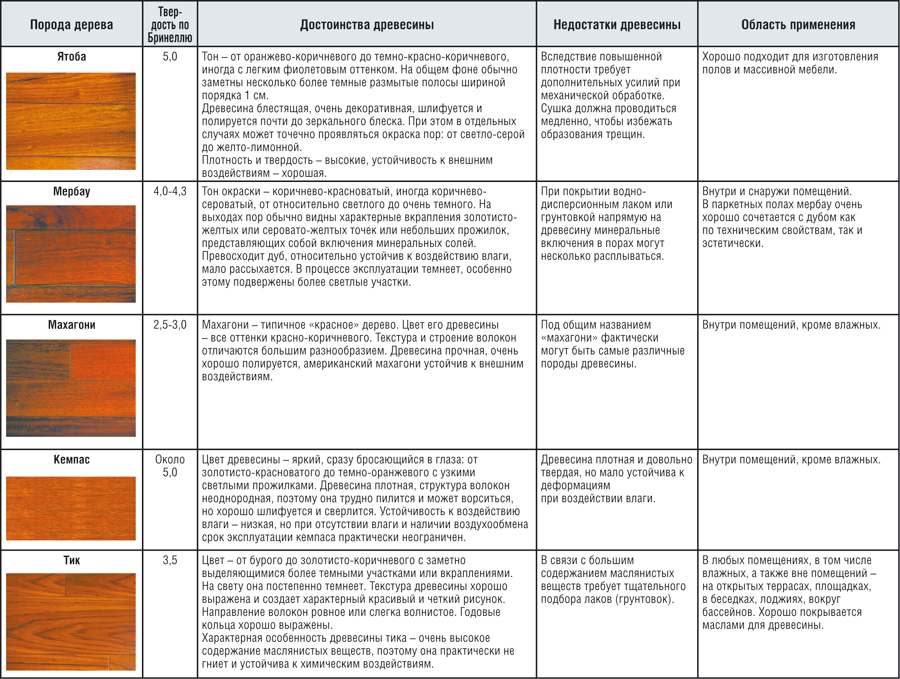

Having decided on the optimal dimensionsparquet board and the type of selection, it is necessary to choose the preferred material of manufacture. Today, floor coverings are made from wood of varying strength and value. When choosing, you should proceed not only from taste preferences, but also from the characteristics of each wood species. Popular types of coverings include: Technological table of parquet.

Technological table of parquet.

- oak;

- wenge;

- beech;

- nut;

- maple;

- cherry;

- camping;

- merbau.

Oak flooring is the standard of durability anddurability. Oak is resistant to abrasion and deformation, and retains an attractive appearance for many years. Maple, cherry and walnut are options for fairly durable and easy-to-care-for coatings. Maple has a pleasant light shade, walnut has a warm orange-brown tone, and cherry has a variety of medium and light tones with a pink tint. Beech boards are no less beautiful, but they are not very durable. Kempas, wenge and merbau are exotic wood species whose popularity is gradually increasing. Kempas comes from Africa and is available in golden and brown tones. Kempas parquet boards are very durable and wear-resistant, but are sensitive to moisture, so it is not recommended to use them in rooms with high humidity. Merbau is a wood species from Indonesia that has a beautiful brown color with golden inclusions. Merbau flooring is resistant to fungus and rot. Wenge is an African wood species with a dark shade and a beautiful pattern. If you plan to create a floor covering that will last for centuries, you should choose a wenge parquet board. Return to contents</a>

Features of the choice of the number of bands

Decorative characteristics of parquet boardsdepend not only on the type of wood used in production and the type of its selection, but also on the number of strips and the type of their installation. Depending on the number of planks in the top layer, parquet boards are distinguished:

- single-band;

- two-band;

- three-band;

- multiband.

Single-strip board has a top layer in the form ofone segment of wood. Using a single piece of wood allows you to preserve the natural pattern of the wood, which gives the flooring a luxurious look. A two-strip board consists of two segments, which can be either whole or divided into several parts. The type of flooring made of two-strip boards depends on the type of wood and the type of selection. Three-strip and multi-strip parquet boards are used to create flooring with an unusual pattern. Three-strip planks consist of three parallel segments, in some versions the segments are offset along the length, which creates a very interesting effect. The top layer of a multi-strip board consists of many segments that are assembled by hand. The multi-strip coating looks very bright, emphasizes the beauty of the wood and makes minor defects almost invisible. Return to contents</a>

Variants of factory processing of a parquet board

To preserve the original beauty of the toplayers of valuable wood parquet boards are varnished or oiled at the final stage of production. Using varnish allows you to give the coating shine. The varnish processing technology is quite complex: initially, putty and a layer of primer are applied, then sanding is performed, after which varnish is applied in seven layers. Varnished boards must be placed in an air chamber, where they are dried and treated with UV rays. Oil treatment is used to give the board a delicate shine without a pronounced shine. Penetrating the structure of the wood, the oil nourishes it, emphasizes the beauty of the natural shade. Having chosen an oiled parquet board, you should be prepared for the need for regular treatment of the floor covering with oil- or wax-based compounds. Studying the above parameters helps to navigate the wide range of parquet boards. It is worth remembering that the quality of the boards depends not only on the material of manufacture, but also on the type of cut and the thickness of the top layer. To add brightness to the interior, it is not at all necessary to buy an option made of exotic wood. An interesting effect can be achieved by using three-strip and multi-strip planks.</ ul>