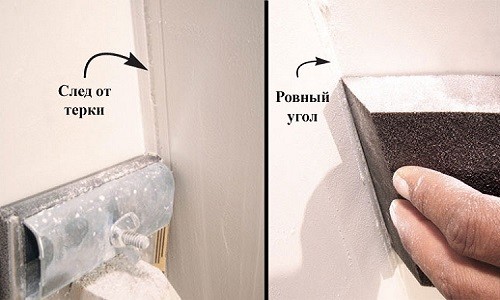

Plastering the walls and their subsequent puttying- these are leveling procedures for subsequent decorative finishing. Moreover, the first is considered a rough process, and the second - more subtle. The process of puttying is also called polishing the walls. Correct grinding of corners.Even when applying a very thin layer of polishing material, bumps and uneven spots cannot but remain on the wall. This happens because of working with a spatula with sharp ends when spreading the putty and connecting one putty part of the wall with others. To reduce the area of alignment, professionals advise using a wide spatula. But even in this case, the joints will still be visible and need to be polished. After puttying, the wall should dry for 24 hours, only then can it be sanded. It is important to remember that you cannot prime the wall after the puttying procedure. Sanding of the walls should be carried out immediately after the puttying process without intermediate stages of work.

Correct grinding of corners.Even when applying a very thin layer of polishing material, bumps and uneven spots cannot but remain on the wall. This happens because of working with a spatula with sharp ends when spreading the putty and connecting one putty part of the wall with others. To reduce the area of alignment, professionals advise using a wide spatula. But even in this case, the joints will still be visible and need to be polished. After puttying, the wall should dry for 24 hours, only then can it be sanded. It is important to remember that you cannot prime the wall after the puttying procedure. Sanding of the walls should be carried out immediately after the puttying process without intermediate stages of work.

Than to polish walls?

Scheme of correct grinding.You can sand the walls with a special sanding machine, or you can do it manually. Professionals consider the second method to be more preferable and high-quality due to the ability to remove roughness in hard-to-reach places. Using a machine polishing method is only advisable for a large area to be finished, but in this case, small flaws still remain, which will then have to be sanded manually. The advantages of machine sanding are considered to be the high speed of the work process and convenience. The downside is that the price of such a machine is quite high, so there is no point in buying it for repairs in only one apartment. For manual grouting of putty, you need to have a sanding mesh or sandpaper on hand. To save money, it is better to buy a roll sandpaper, because its consumption when polishing putty is very high. To attach the abrasive and make the work easier, you also need to buy a block.

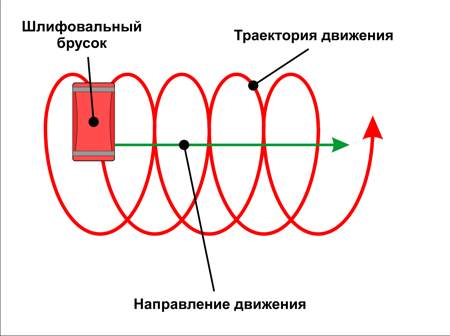

Scheme of correct grinding.You can sand the walls with a special sanding machine, or you can do it manually. Professionals consider the second method to be more preferable and high-quality due to the ability to remove roughness in hard-to-reach places. Using a machine polishing method is only advisable for a large area to be finished, but in this case, small flaws still remain, which will then have to be sanded manually. The advantages of machine sanding are considered to be the high speed of the work process and convenience. The downside is that the price of such a machine is quite high, so there is no point in buying it for repairs in only one apartment. For manual grouting of putty, you need to have a sanding mesh or sandpaper on hand. To save money, it is better to buy a roll sandpaper, because its consumption when polishing putty is very high. To attach the abrasive and make the work easier, you also need to buy a block. Grinding is done with circular movements.When buying sandpaper, you need to look at the marking, because the degree of abrasive graininess plays an important role in sanding walls. Foreign sandpaper will have the symbol "p" and numbers 24-600. The grains are larger, the smaller the number. When sanding putty, abrasives with the designations "p-100", "p-60" and "p-80" are most often used. As for domestically produced sandpaper, it is marked with the letter "n" and numbers from 4 to 80. The designation of the smallest sandpaper differs from the generally accepted marking. Zero means abrasive "m-40". When marking domestic sandpaper, with a decrease in the digital value, the degree of abrasive also decreases. This distinguishes paper made in Russia from imported material. Sandpaper has a significant drawback. The base tends to wear out and wear out quickly, becoming clogged with dust. The material has to be changed frequently, so it is better to use a mesh for grinding instead of sandpaper. This material is more expensive than sandpaper, but its consumption is much less. The mesh is marked as imported sandpaper. Return to contents</a>

Grinding is done with circular movements.When buying sandpaper, you need to look at the marking, because the degree of abrasive graininess plays an important role in sanding walls. Foreign sandpaper will have the symbol "p" and numbers 24-600. The grains are larger, the smaller the number. When sanding putty, abrasives with the designations "p-100", "p-60" and "p-80" are most often used. As for domestically produced sandpaper, it is marked with the letter "n" and numbers from 4 to 80. The designation of the smallest sandpaper differs from the generally accepted marking. Zero means abrasive "m-40". When marking domestic sandpaper, with a decrease in the digital value, the degree of abrasive also decreases. This distinguishes paper made in Russia from imported material. Sandpaper has a significant drawback. The base tends to wear out and wear out quickly, becoming clogged with dust. The material has to be changed frequently, so it is better to use a mesh for grinding instead of sandpaper. This material is more expensive than sandpaper, but its consumption is much less. The mesh is marked as imported sandpaper. Return to contents</a>

Wall polishing: the work process

Walls can only be polished after they have been completelyputty drying. Before starting work, it is necessary to cover the doorways with a damp cloth so that dust does not get into other rooms. The sanding process is quite dusty, so you should also think about your own suit, the fabric of which should be dense. You also need to put on a respirator, gloves and eye protection glasses. You can start sanding the walls after the last applied layer of putty has completely dried. We attach the sandpaper to the block for grouting, take the corner as the starting line and begin working. You need to rub with light circular movements, without pressing on the block. It is better not to go over the same place twice to avoid differences in altitude. To check the quality of polishing, it is not enough to run your hand over the treated area. It is better to direct a powerful beam of light from a flashlight or spotlight at an acute angle to this area. Areas with identified defects should be brought to mind using a finer abrasive. It is necessary to take into account the paint that will cover the surface after processing. Matte will help to hide some roughness, but glossy will require higher quality polishing. If the wall puttying is done relatively well, and for the final finishing of the room, for example, vinyl wallpaper will be used, then sanding can be omitted. With high-quality preparatory puttying work, there is no need to sand the walls completely. In this case, you can resort to only local work. After puttying, if wallpapering is not envisaged, the walls are painted with a control layer. Water is added to the paint that will then be applied to the wall and applied to the wall, as a result of which all the irregularities are visible. The imperfections are puttied again, allowed to dry and polished again with an abrasive. After finishing sanding, the surfaces are cleaned of dust with a vacuum cleaner. The next step is priming the walls, after which wallpaper is glued or paint is applied.

Walls can only be polished after they have been completelyputty drying. Before starting work, it is necessary to cover the doorways with a damp cloth so that dust does not get into other rooms. The sanding process is quite dusty, so you should also think about your own suit, the fabric of which should be dense. You also need to put on a respirator, gloves and eye protection glasses. You can start sanding the walls after the last applied layer of putty has completely dried. We attach the sandpaper to the block for grouting, take the corner as the starting line and begin working. You need to rub with light circular movements, without pressing on the block. It is better not to go over the same place twice to avoid differences in altitude. To check the quality of polishing, it is not enough to run your hand over the treated area. It is better to direct a powerful beam of light from a flashlight or spotlight at an acute angle to this area. Areas with identified defects should be brought to mind using a finer abrasive. It is necessary to take into account the paint that will cover the surface after processing. Matte will help to hide some roughness, but glossy will require higher quality polishing. If the wall puttying is done relatively well, and for the final finishing of the room, for example, vinyl wallpaper will be used, then sanding can be omitted. With high-quality preparatory puttying work, there is no need to sand the walls completely. In this case, you can resort to only local work. After puttying, if wallpapering is not envisaged, the walls are painted with a control layer. Water is added to the paint that will then be applied to the wall and applied to the wall, as a result of which all the irregularities are visible. The imperfections are puttied again, allowed to dry and polished again with an abrasive. After finishing sanding, the surfaces are cleaned of dust with a vacuum cleaner. The next step is priming the walls, after which wallpaper is glued or paint is applied.