Nowadays, more and more people are strivingmake a stretch ceiling in your apartment. It is beautiful, convenient, practical and does not require too much expense. Especially if . It is no secret that many are afraid of this, fearing to spoil the material or get something different from what they dreamed of. Therefore, they prefer the usual whitewashing or painting. However, it is not as difficult as it may seem at first. Using a stretch ceiling will emphasize the individuality and sophistication of your living room. The advantages of stretch structures include:

Using a stretch ceiling will emphasize the individuality and sophistication of your living room. The advantages of stretch structures include:

What is this coverage?

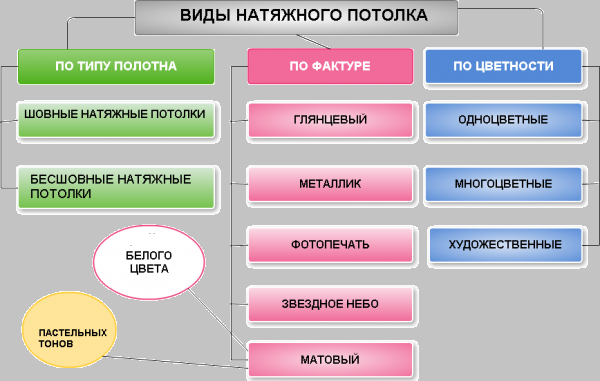

Types of stretch ceilings.Stretch ceilings are made of polyvinyl chloride film (PVC) or polyester fabric stretched over a baguette frame located along the perimeter of the ceiling. The baguette is attached to the supporting ceiling or walls and can be hidden or visible. The film is secured to the baguette using locks or special wedges by heating it with a construction hair dryer or a special heat gun. It is not very difficult to install a stretch ceiling with your own hands, but this operation requires attention, careful preparation and a number of preliminary works. The installation process itself includes:

Types of stretch ceilings.Stretch ceilings are made of polyvinyl chloride film (PVC) or polyester fabric stretched over a baguette frame located along the perimeter of the ceiling. The baguette is attached to the supporting ceiling or walls and can be hidden or visible. The film is secured to the baguette using locks or special wedges by heating it with a construction hair dryer or a special heat gun. It is not very difficult to install a stretch ceiling with your own hands, but this operation requires attention, careful preparation and a number of preliminary works. The installation process itself includes:

Return to Contents</a>

Measurement of the perimeter of the ceiling

Stages of installation of a suspended ceiling.Before installing a stretch ceiling with your own hands, you need to carefully measure the shape and perimeter of the room ceiling. This is necessary to calculate the length and shape of the supporting frame of the stretch film, the area and size of the canvas, and determine the joints or seams of individual strips of film. The perimeter is measured at the level of fastening the supporting baguette installed on the ceiling or walls of the room. The measurement result must be put on paper, the measurement error should not exceed 5 mm. On paper, you need to mark the location of door and window openings, the location of heating pipes, the number and location of lighting fixtures. During the measurement, it is advisable to make preliminary markings for fastening the supporting frame using a construction bubble or laser level. Based on the measurement results, the total length of the supporting profile and the number of profile elements of a standard length of 2 m are calculated. When calculating the number of baguette profiles, it is necessary to take into account losses during cutting and joining of baguette elements. Return to contents</a>

Stages of installation of a suspended ceiling.Before installing a stretch ceiling with your own hands, you need to carefully measure the shape and perimeter of the room ceiling. This is necessary to calculate the length and shape of the supporting frame of the stretch film, the area and size of the canvas, and determine the joints or seams of individual strips of film. The perimeter is measured at the level of fastening the supporting baguette installed on the ceiling or walls of the room. The measurement result must be put on paper, the measurement error should not exceed 5 mm. On paper, you need to mark the location of door and window openings, the location of heating pipes, the number and location of lighting fixtures. During the measurement, it is advisable to make preliminary markings for fastening the supporting frame using a construction bubble or laser level. Based on the measurement results, the total length of the supporting profile and the number of profile elements of a standard length of 2 m are calculated. When calculating the number of baguette profiles, it is necessary to take into account losses during cutting and joining of baguette elements. Return to contents</a>

Mounting the suspension support frame

To install a stretch ceiling we need: List of tools for installation of stretch ceilings.

List of tools for installation of stretch ceilings.

- perforator;

- heat gun;

- gas cylinder;

- set of tools;

- ladder;

- building level.

Fastening the supporting frame of the suspended ceiling towalls or ceiling of the room is carried out with screws, self-tapping screws or dowels with a step of no more than 10 cm. During installation, the profiles must be leveled, the joining of individual elements is carried out on a flat wall surface. To form corners, the profile elements are cut and bent at an angle of 90º, taking into account both the external and internal corners of the room. To check the correctness of the joining of the corners and the cutting of the profile, it can be pre-laid on the floor of the room. The height of the frame installation is determined by the nature of the room and the height of the spotlights. If the height of the lamps is greater than the width of the supporting profile, the frame is installed on the walls at a distance of 10-12 cm from the supporting ceiling. If the only lighting fixture is planned to be used in the room, for example, a chandelier, then the profile of the supporting frame of the stretch ceiling can be attached almost tightly to the supporting surface. During the installation of the baguette elements, it is necessary to control their position using a tension cord and a building level, taking into account the preliminary markings. In the corner joints of the frame, it is necessary to additionally fix one screw at a distance of 2 cm from the corner. After installing the frame, it is necessary to fix the spotlights, conduct and connect the power supply wires. Installation of lighting fixtures and electrical wiring must be carried out taking into account safety regulations. The power of incandescent lamps in lighting fixtures should not exceed 40-50 watts, which is due to fire safety. Return to contents</a>

Installation of a ceiling tension cloth

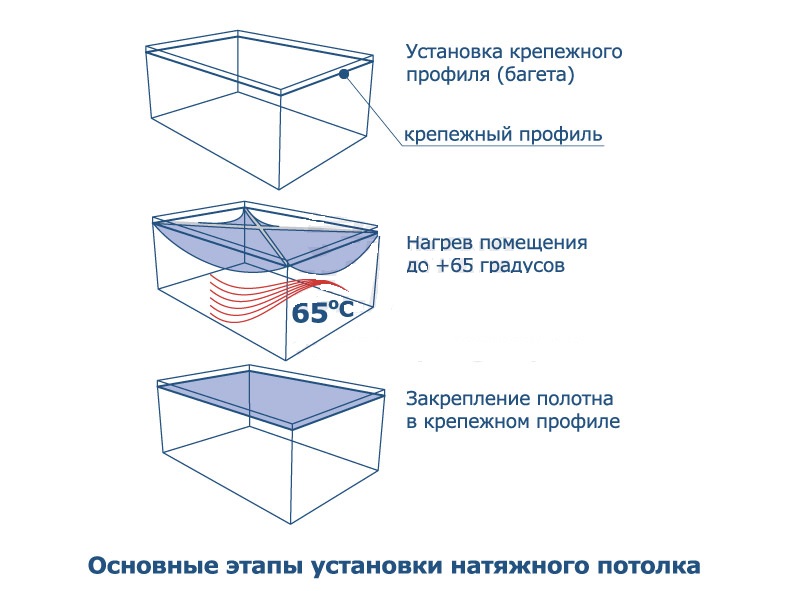

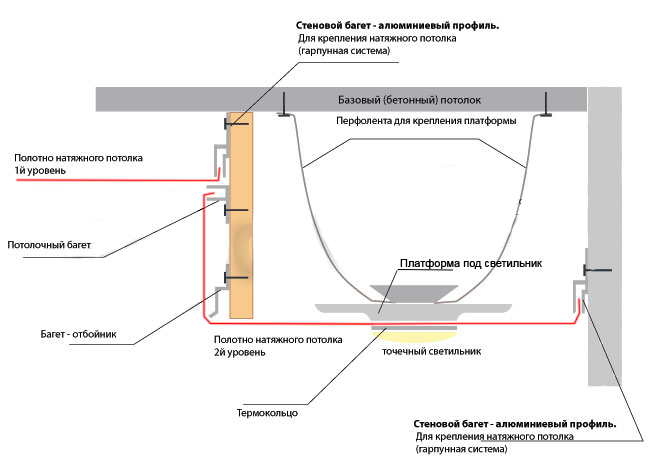

Scheme of a two-level stretch ceiling.The stretch ceiling sheet is fixed in the baguette grooves - the frame installed along the perimeter of the room. When installing the sheet, the room is heated to a temperature of about 40 ° C, the sheet itself must be heated to 60 ° C, at which point it becomes elastic and stretches, which facilitates its fastening. The sheet is fixed from the base corner, the location of which is indicated in the instructions. The corner is fixed in the baguette groove using a spatula until the lock clicks, and the sheet is also fixed at a distance of 10-15 cm from the corner. The remaining corners are pre-suspended to the baguette with clothespins or clamps. The sheet is aligned, the diagonal corner opposite the base corner is fixed, and then the side edges of the sheet are fixed. Half of the side is fixed from the base corner to the frame, after which half of the side is fixed from the opposite corner. This is required for uniform tension of the polymer film. After this, the remaining corners and sides of the film are mounted. The installation should be done carefully, it is necessary to avoid contamination of the canvas, its overheating above 60-70°C and damage to its surface by sharp objects.

Scheme of a two-level stretch ceiling.The stretch ceiling sheet is fixed in the baguette grooves - the frame installed along the perimeter of the room. When installing the sheet, the room is heated to a temperature of about 40 ° C, the sheet itself must be heated to 60 ° C, at which point it becomes elastic and stretches, which facilitates its fastening. The sheet is fixed from the base corner, the location of which is indicated in the instructions. The corner is fixed in the baguette groove using a spatula until the lock clicks, and the sheet is also fixed at a distance of 10-15 cm from the corner. The remaining corners are pre-suspended to the baguette with clothespins or clamps. The sheet is aligned, the diagonal corner opposite the base corner is fixed, and then the side edges of the sheet are fixed. Half of the side is fixed from the base corner to the frame, after which half of the side is fixed from the opposite corner. This is required for uniform tension of the polymer film. After this, the remaining corners and sides of the film are mounted. The installation should be done carefully, it is necessary to avoid contamination of the canvas, its overheating above 60-70°C and damage to its surface by sharp objects. Installation of a spotlight in a stretch ceilingceiling If creases and folds form on the canvas, they are additionally carefully heated, smoothed and leveled until a flat surface is obtained. It should be taken into account that after cooling, the stretch ceiling film shrinks by about 7-10%, so during installation, the canvas should not be overstretched. After installation, the canvas is heated again over the entire surface for 20-30 minutes, which allows you to identify and eliminate installation errors. The final stage is the installation of decorative plugs along the perimeter of the fastening frame-baguette, installation and connection of lighting fixtures. Return to contents</a>

Installation of a spotlight in a stretch ceilingceiling If creases and folds form on the canvas, they are additionally carefully heated, smoothed and leveled until a flat surface is obtained. It should be taken into account that after cooling, the stretch ceiling film shrinks by about 7-10%, so during installation, the canvas should not be overstretched. After installation, the canvas is heated again over the entire surface for 20-30 minutes, which allows you to identify and eliminate installation errors. The final stage is the installation of decorative plugs along the perimeter of the fastening frame-baguette, installation and connection of lighting fixtures. Return to contents</a>

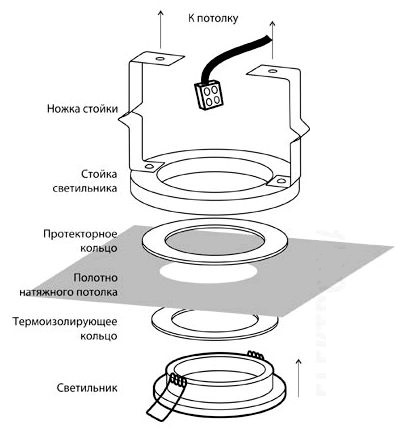

Installation of lighting devices

For installation of lighting fixtures in a stretch ceilingTechnological holes are cut in the canvas, the diameter of which is determined by the design of the lighting fixtures. To protect the canvas from damage, flat plastic protective rings are pre-glued to its surface at the attachment points of the lighting fixtures, protecting the film from ruptures. In particular, for example, when installing a chandelier, a plastic protective ring is glued to the surface of the stretch ceiling canvas, the diameter of which is smaller than the diameter of the decorative ceiling cap of the chandelier. A hole is cut inside the ring in the canvas, through which electrical wires are pulled to connect the lamp, and the chandelier is hung on a hook. In some cases, the protective plastic ring is additionally secured with self-tapping screws to a wooden plate installed on the supporting ceiling flush with the film, which eliminates sagging of the canvas when it is heated by the chandelier lamps. Installation and connection of spotlights is carried out similarly, according to pre-made markings.