You can anticipate as much as you like what it will be likeinterior after the new original wallpaper beautifully lays on the walls of the room. But all these dreams are unlikely to come true if the master neglects, at first glance, one not very remarkable operation. Any, even impeccable finishing will not be able to truly decorate the room if the walls were not fully prepared for wallpapering according to all the rules. Before gluing wallpaper on a concrete wall,a putty compound is applied, after which the wall is polished with pumice. The importance of this type of work is emphasized by the special attention that experienced builders pay to this process. Without this attention and a fairly long time that must be devoted to preparatory operations, it is impossible to obtain an attractive and high-quality result. Therefore, at least some of this time should be devoted to familiarizing yourself with the main stages of preparing walls for wallpapering.

Before gluing wallpaper on a concrete wall,a putty compound is applied, after which the wall is polished with pumice. The importance of this type of work is emphasized by the special attention that experienced builders pay to this process. Without this attention and a fairly long time that must be devoted to preparatory operations, it is impossible to obtain an attractive and high-quality result. Therefore, at least some of this time should be devoted to familiarizing yourself with the main stages of preparing walls for wallpapering.

Materials and tools for work

In order to level the walls as effectively as possible, you will need a set of materials and tools: Wall cleaning diagram: a – cleaning with a scraper; b – smoothing with a flat or articulated float; c – diagram of the movement of the working tool.

Wall cleaning diagram: a – cleaning with a scraper; b – smoothing with a flat or articulated float; c – diagram of the movement of the working tool.

- rubber spatula;

- notched trowel;

- metal beacons;

- putty;

- mixer for construction;

- water;

- respirator;

- protective film;

- primer;

- plaster mixture based on gypsum;

- abrasive emery paper;

- a metal spatula;

- building level;

- rule;

- paint roller;

- bucket.

Return to Contents</a>

The basic requirements for walls under wallpapering

Preparing the walls should take no less time than the actual wallpapering. There are at least 4 main reasons why this must be done:

Based on the practice of finishing works, it is possible to determine the basic requirements for the wall on which the wallpaper will be glued. Thus, the wall should be: Scheme for calculating the area of a room for wallpapering.

Scheme for calculating the area of a room for wallpapering.

- strong enough (if nothing is crumbled on the wall with a fingernail or a key from the surface, it can be considered strong);

- dry (a wet wall will not absorb moisture from the glue, which will prevent strong adhesion);

- cleaned and plain (to avoid defects after gluing, advise beforehand to attach to the wall wallpaper and make sure that through them do not shine spots of different tones);

- devoid of streaks of lime (when impregnated with glue such areas will not absorb moisture and here the wallpaper will exfoliate).

In order to comply with all these requirements, it is necessary to go through 3 preparatory stages. Return to the table of contents</a>

Preparation of walls for pasting: cleaning stage

The first task for the worker is to cleanall walls to which the paper covering will be glued, from fragments of old finishing materials, including unnecessary wallpaper, paints and varnishes, whitewash, etc. The old wallpaper can be removed using a plastering trowel or spatula, prying up the edge of the canvas. To facilitate the process, the old covering can be slightly moistened with water. Removing white marks:a - cleaning the surface with a spatula, b - smearing with glue. The paint is removed either manually, by scraping off the hardened layer of paint with a spatula, or with an electric drill, on which a special grinding attachment in the form of a metal brush is installed. In this case, it is undesirable to allow such movements that would seriously damage the base. And one must not forget about personal protective equipment when cleaning the walls. Old unnecessary whitewash is removed with ordinary water. To do this, it is enough to thoroughly wet the brush in a bucket and then wash the whitewashed place with it until the noticed defect completely disappears. Return to the table of contents</a>

Removing white marks:a - cleaning the surface with a spatula, b - smearing with glue. The paint is removed either manually, by scraping off the hardened layer of paint with a spatula, or with an electric drill, on which a special grinding attachment in the form of a metal brush is installed. In this case, it is undesirable to allow such movements that would seriously damage the base. And one must not forget about personal protective equipment when cleaning the walls. Old unnecessary whitewash is removed with ordinary water. To do this, it is enough to thoroughly wet the brush in a bucket and then wash the whitewashed place with it until the noticed defect completely disappears. Return to the table of contents</a>

Leveling and fighting bacteria

At the second stage, it is important to assess the physicalthe condition of the wall surface. In particular, it is necessary to establish how uneven the surface being processed is and in what places the main unevenness (depressions and bumps) is located. Currently, finishers have the opportunity to determine such defects using a modern device - a laser level. However, its absence is not a hindrance. In this case, you can use the old proven method - checking the condition of the wall with a cord. This long cord, previously generously rubbed with chalk, is stretched across the entire wall and taken by the ends by two workers. They stand in opposite corners of the wall and draw the stretched cord along the wall from top to bottom. Sealing joints in walls:a - seam; b - putty; c - sealing with gauze; g - secondary putty; d - sanding with sandpaper. In this case, chalk remains on flat areas. At the same time, the existing depressions are not whitewashed, and the bumps form poorly drawn fragments around themselves. After this, the marked bumps are removed with a chisel and hammer (this can be done with a hammer drill). The depressions are plastered until a flat surface is obtained. The cracks and chips noticed during light tapping of the wall are also sealed with putty. At the end of the process, the wall is sanded with sandpaper. In addition, it is necessary to carry out antibacterial treatment of the leveled surface. Of course, this should be done only after the worker makes sure that there are no fungal formations on the wall. Special antibacterial chemicals or a solution of boric alcohol are used against bacteria. After the wall has been soaked with the above liquids, it must be allowed to dry. Return to contents</a>

Sealing joints in walls:a - seam; b - putty; c - sealing with gauze; g - secondary putty; d - sanding with sandpaper. In this case, chalk remains on flat areas. At the same time, the existing depressions are not whitewashed, and the bumps form poorly drawn fragments around themselves. After this, the marked bumps are removed with a chisel and hammer (this can be done with a hammer drill). The depressions are plastered until a flat surface is obtained. The cracks and chips noticed during light tapping of the wall are also sealed with putty. At the end of the process, the wall is sanded with sandpaper. In addition, it is necessary to carry out antibacterial treatment of the leveled surface. Of course, this should be done only after the worker makes sure that there are no fungal formations on the wall. Special antibacterial chemicals or a solution of boric alcohol are used against bacteria. After the wall has been soaked with the above liquids, it must be allowed to dry. Return to contents</a>

Wall preparation: primer before pasting

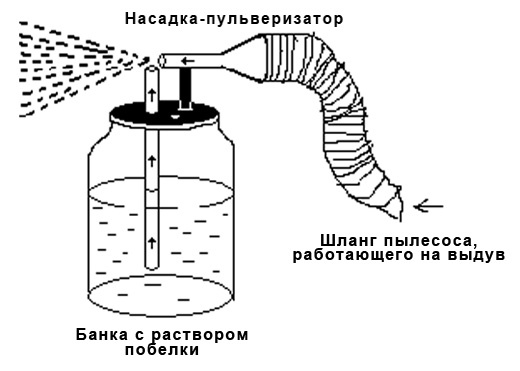

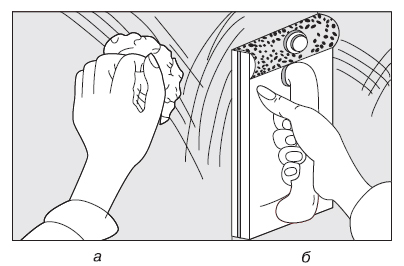

Once the walls have been leveled, the final preparatory stage begins - covering the surface of the partitions with a special primer. Preparing painted walls:a - washing; b - sanding. The tools used in this operation are a plaster roller or a wide brush. You can use a spray gun instead, but in this case, about 20% more primer will be used than with the manual method. The primer is applied to the wall from top to bottom with uniform movements. The surface should be wetted quite abundantly. Applying priming liquids will improve the adhesion of the wallpaper to the base and will prevent putrefactive bacteria and mold from developing under their layer. In order to carry out high-quality wallpapering in the future, it is necessary to let the walls dry completely after treating with a primer. Only under this condition can you hope to get a beautiful, high-quality and reliable result. Return to the table of contents</a>

Preparing painted walls:a - washing; b - sanding. The tools used in this operation are a plaster roller or a wide brush. You can use a spray gun instead, but in this case, about 20% more primer will be used than with the manual method. The primer is applied to the wall from top to bottom with uniform movements. The surface should be wetted quite abundantly. Applying priming liquids will improve the adhesion of the wallpaper to the base and will prevent putrefactive bacteria and mold from developing under their layer. In order to carry out high-quality wallpapering in the future, it is necessary to let the walls dry completely after treating with a primer. Only under this condition can you hope to get a beautiful, high-quality and reliable result. Return to the table of contents</a>

Moments to look out for

In the event that wallpapering will beis made on a plasterboard panel, the wall should be treated with a polymer primer in just one layer. After carefully sealing the seams between the plasterboard sheets with putty, its surface is primed again. When finishing a wooden base with wallpaper, a fabric covering can be pre-stretched onto it. To do this, wet fabric is stretched on the wall, securing it with nails at the edges. After drying, the fabric is stretched and forms a layer that protects the wallpaper from warping in the event of possible deformation of the wood. If all the specified requirements for the condition of the wall surface are strictly observed, and the preparation rules are followed, further work on pasting with wallpaper will give the master real pleasure.