The modern construction market offersa wide range of materials that provide thermal insulation of the premises. Insulation of walls from the inside with cork is becoming increasingly popular among buyers. This material has many advantages, among which we can highlight its natural origin and environmental friendliness. Cork flooring has many advantages, including:which can be distinguished by its natural origin. It perfectly absorbs noise, is resistant to all types of deformation. Cork insulation has firmly won the respect of those who prefer to carry out finishing of residential buildings and insulation of walls of premises only with the help of natural means.

Cork flooring has many advantages, including:which can be distinguished by its natural origin. It perfectly absorbs noise, is resistant to all types of deformation. Cork insulation has firmly won the respect of those who prefer to carry out finishing of residential buildings and insulation of walls of premises only with the help of natural means.

Features of the material, its advantages and disadvantages

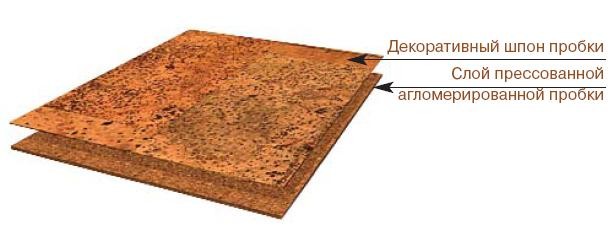

Insulation of walls with cork is practicedfor quite a long time. The high level of thermal insulation of this substance is achieved not by special processing of raw materials, but due to the internal structure. This material is obtained only from the bark of the cork oak. Since this plant has a rather narrow distribution area, the heat insulator made from it is not cheap. From the inside, the material looks like a series of microscopic, hermetically sealed chambers, each of which is filled with a mixture of gases. The main component is inert nitrogen. Such a structure provides even a thin plate with excellent thermal insulation properties, and in addition, elasticity. The panel restores its original shape without damage even after prolonged deformation. In the manufacture of cork heat insulator, various raw materials are used, so the panels are divided into several types: Cork covering scheme.

Cork covering scheme.

It should be noted that high-quality agglomerate will contain suberin - a highly durable adhesive of natural origin. Advantages of cork covering:

Return to Contents</a>

Varieties of cork material

Thermal conductivity coefficients of variousmaterials. The most common form of release is heat insulator under wallpaper in the form of rolls or thin tiles. The width can vary from 300 to 1000 mm, so you should carefully measure the surfaces to be treated and calculate the required amount of material before purchasing. Among the disadvantages of cork is its high price, so you should protect yourself from unnecessary expenses. Give preference to brands whose products contain a minimum amount of foreign impurities. If you plan to finish a residential premises, the best option would be a roll heat insulator with antibacterial impregnation. It is non-toxic for the human body, but it will perfectly protect the walls from bacteria and fungus. Cork material does not have good moisture-resistant characteristics. Granules can swell due to exposure to water, which will entail deformation of the coating. Therefore, additional waterproofing of the surface may be needed. When installing roll agglomerate, one must not forget about the thermoplasticity of the cork. This means that the material should be kept for two days inside the room that will be pasted. The work is carried out in a warm place, at a temperature of 18-25 degrees, and humidity below 60%. To fix the material to the wall surface, acrylic-based or contact adhesive mixtures are used. The former are easier to work with, and the latter are more reliable: they are applied both to the roll and to the wall. Return to contents</a>

Thermal conductivity coefficients of variousmaterials. The most common form of release is heat insulator under wallpaper in the form of rolls or thin tiles. The width can vary from 300 to 1000 mm, so you should carefully measure the surfaces to be treated and calculate the required amount of material before purchasing. Among the disadvantages of cork is its high price, so you should protect yourself from unnecessary expenses. Give preference to brands whose products contain a minimum amount of foreign impurities. If you plan to finish a residential premises, the best option would be a roll heat insulator with antibacterial impregnation. It is non-toxic for the human body, but it will perfectly protect the walls from bacteria and fungus. Cork material does not have good moisture-resistant characteristics. Granules can swell due to exposure to water, which will entail deformation of the coating. Therefore, additional waterproofing of the surface may be needed. When installing roll agglomerate, one must not forget about the thermoplasticity of the cork. This means that the material should be kept for two days inside the room that will be pasted. The work is carried out in a warm place, at a temperature of 18-25 degrees, and humidity below 60%. To fix the material to the wall surface, acrylic-based or contact adhesive mixtures are used. The former are easier to work with, and the latter are more reliable: they are applied both to the roll and to the wall. Return to contents</a>

Installation of cork insulation on the wall with your own hands

To insulate the walls from the insideusing such material, installation work must be carried out on the work surface. Before starting the process, make sure that the walls of the room are perfectly flat. This can be checked using a building level. If the surface of the wall is not flat enough, it should be plastered and any protrusions, cracks, depressions or other defects should be removed. After that, let the room dry thoroughly. Insulation of walls with cork material cannot be carried out on damp surfaces: this will lead to deformation of the panels and the appearance of fungus. When installing insulation, strictly follow the instructions for the adhesive used. Strict adherence to the technology will ensure the strength and integrity of the coating during operation. Apply the cork sheet covered with glue to the wall and secure it. At this stage, you need to be careful and precise: most adhesive bases for cork set almost instantly, and you will no longer be able to change the position of the panel after you have applied it to the wall. Insulation of walls with cork should be carried out in carefully ventilated rooms, since many adhesive bases are toxic and have a sharp unpleasant odor. This type of finishing, such as insulating walls from the inside with cork, will be an excellent opportunity to reduce heat loss. Even though the panels are more expensive than synthetic materials, they remain optimal, especially for those who prefer a natural atmosphere in the house.