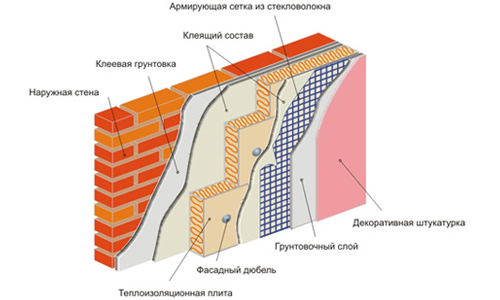

Nowadays the cost of heatingenergy resources tends to grow constantly. It is not only desirable but also necessary to reduce heat loss in such conditions, this will allow saving the budget on paying bills for gas and electricity consumption. The most effective measure in this direction can be considered insulation of the load-bearing walls of the house. Scheme of wall insulation with foam plastic.One of the most popular materials for this today is polystyrene foam. It is quite possible to insulate walls with polystyrene foam yourself, without hiring labor, which is very profitable from the financial side. The cost of the material is relatively low, so if you follow certain rules and recommendations, the insulation process will not cause large losses to the family budget. At the same time, the result will be quite effective.

Scheme of wall insulation with foam plastic.One of the most popular materials for this today is polystyrene foam. It is quite possible to insulate walls with polystyrene foam yourself, without hiring labor, which is very profitable from the financial side. The cost of the material is relatively low, so if you follow certain rules and recommendations, the insulation process will not cause large losses to the family budget. At the same time, the result will be quite effective.

Properties and Features of Polyfoam

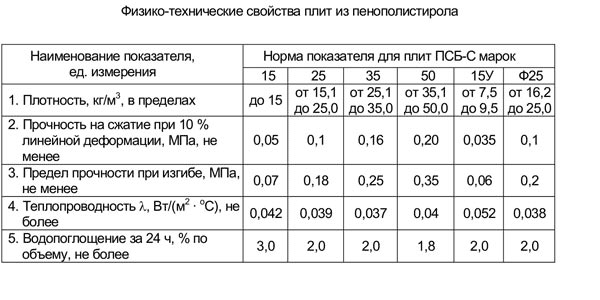

It is made of expanded polystyrene,Its most significant properties are very low specific gravity, low thermal conductivity and complete impermeability to moisture. That is why insulation of walls with foam plastic is carried out in the vast majority of cases from the outside. The material has not only heat-insulating properties, but also sound-absorbing ones. It can be used in combination with other insulating materials, but this is usually not necessary. The foam plastic itself is enough, you just need to choose its density and thickness correctly. Table of characteristics of polystyrene foam.The material is offered for sale in retail chains either in the form of slabs or rolled into rolls, which again depends on the thickness and density. The degree of thermal insulation of the wall covered with it depends on the thickness of the foam plastic. As a rule, a 5 cm thick slab is taken for fastening to the wall surface. This immediately reduces the loss of thermal energy in the interior of the house by almost 2 times. If this is considered insufficient, you can take 10 cm, which will immediately increase the cost. To correctly calculate the required thickness, you need to take into account the material from which the load-bearing walls are erected, their thickness, as well as the average air temperature in winter in this area. In addition to thickness, the density of the material is of no small importance. Experts recommend covering external walls with foam plastic with a density rating of 25. If it is lower, then the vulnerability of the wall surface to mechanical damage will be too high. If it is higher, then this unreasonably overstates the cost of the material, since the density has an extremely insignificant effect on thermal insulation indicators. Return to contents</a>

Table of characteristics of polystyrene foam.The material is offered for sale in retail chains either in the form of slabs or rolled into rolls, which again depends on the thickness and density. The degree of thermal insulation of the wall covered with it depends on the thickness of the foam plastic. As a rule, a 5 cm thick slab is taken for fastening to the wall surface. This immediately reduces the loss of thermal energy in the interior of the house by almost 2 times. If this is considered insufficient, you can take 10 cm, which will immediately increase the cost. To correctly calculate the required thickness, you need to take into account the material from which the load-bearing walls are erected, their thickness, as well as the average air temperature in winter in this area. In addition to thickness, the density of the material is of no small importance. Experts recommend covering external walls with foam plastic with a density rating of 25. If it is lower, then the vulnerability of the wall surface to mechanical damage will be too high. If it is higher, then this unreasonably overstates the cost of the material, since the density has an extremely insignificant effect on thermal insulation indicators. Return to contents</a>

Consumables and preparatory work for covering the walls with polystyrene foam

Схема подготовки стены к утеплению пенопластом.First of all, you need to calculate the amount of foam plastic that will be used to insulate this wall. To do this, divide its area by the area of one plate, subtract the area of window and door openings from this amount. It is advisable to purchase a small amount of foam plastic with a small reserve. In addition, you need to buy a primer, special glue for attaching foam plastic, dry plaster, reinforcing fiberglass mesh, reinforcing corners, a starting metal profile and dowels, regular and with umbrella-shaped heads. In addition to them, to attach foam plastic to the walls with your own hands, you will need tools such as an electric drill, drills of different calibers, a spatula, a container for mortar, a tape measure, a level, a plumb line, a bag knife, a construction stapler and a roll of cord or fishing line. Before you start insulating the walls with foam plastic with your own hands, you need to properly prepare their surface. It is necessary to remove all old plaster, layers of paint, lime and other similar coatings. Then, using a hose, wash off dust, dirt, mold and mildew stains, and fill cracks and depressions with putty. After that, the cleaned surface is covered with a primer, preferably a special one, produced by the German company "Ceresit". It penetrates deeply into the wall surface and holds well. Only after this can you begin covering the walls with foam plastic. Return to contents</a>

Схема подготовки стены к утеплению пенопластом.First of all, you need to calculate the amount of foam plastic that will be used to insulate this wall. To do this, divide its area by the area of one plate, subtract the area of window and door openings from this amount. It is advisable to purchase a small amount of foam plastic with a small reserve. In addition, you need to buy a primer, special glue for attaching foam plastic, dry plaster, reinforcing fiberglass mesh, reinforcing corners, a starting metal profile and dowels, regular and with umbrella-shaped heads. In addition to them, to attach foam plastic to the walls with your own hands, you will need tools such as an electric drill, drills of different calibers, a spatula, a container for mortar, a tape measure, a level, a plumb line, a bag knife, a construction stapler and a roll of cord or fishing line. Before you start insulating the walls with foam plastic with your own hands, you need to properly prepare their surface. It is necessary to remove all old plaster, layers of paint, lime and other similar coatings. Then, using a hose, wash off dust, dirt, mold and mildew stains, and fill cracks and depressions with putty. After that, the cleaned surface is covered with a primer, preferably a special one, produced by the German company "Ceresit". It penetrates deeply into the wall surface and holds well. Only after this can you begin covering the walls with foam plastic. Return to contents</a>

Heat insulation of walls with foam plastic by one's own hands: technology and sequence of actions

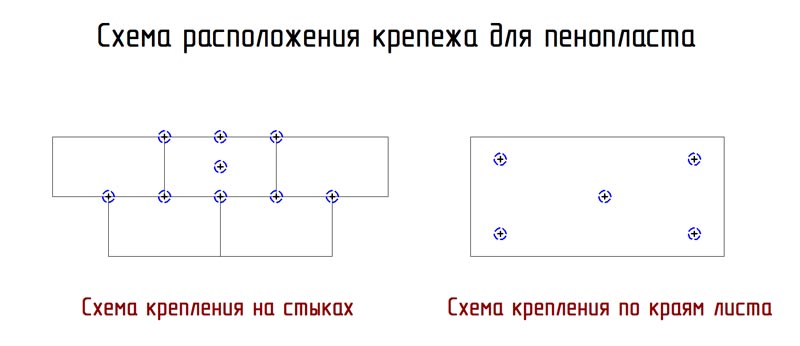

Layout diagram of fasteners for foam plastic.The process of insulating external walls with foam plastic involves a combined method of fastening. First, the material is glued to the wall surface, and then fastened with umbrella-type dowels. If you neglect one of these procedures, the quality of the coating will suffer so much that after a year it will have to be fastened again. To begin with, a metal profile is fastened with dowels at a distance of 50-60 cm from the ground surface and leveled with a level. The first row of foam plastic slabs is laid on it, this will ensure even laying of all subsequent ones. Cement-based glue is applied to one of them in heaps in 3 rows of 4-5 points, the slab is pressed tightly against the wall. The procedure is very similar to laying tiles. However, in the case of foam plastic, the seams are staggered not for the strength of the insulation itself, but to prevent cracks in the plaster that will cover it in the future. Unlike tiles, it is cut very easily with a bag knife. This arrangement is especially important at the corners, where the risk of cracks is highest. Using a plumb line, the alignment of the plane of each row is controlled. After the glue has slightly set, about a day later, 5 umbrella dowels are screwed into the center and corners of each plate. It should be remembered that you cannot leave the walls covered with foam plastic for a long time. Ultraviolet rays begin to destroy it, so immediately after final fastening it must be covered with plaster. Before applying the plaster, a reinforcing fiberglass mesh must be fixed to the insulation, since the walls made of foam plastic without it will not have a strong bond with the plaster layer. It is attached with a special reinforcement glue, which is produced by the same company "Ceresit". The surface of the foam plastic plates is smeared with a continuous thin layer of glue, and the mesh is pressed into it. Excess glue streaks must be removed immediately with a spatula. The side edges of the mesh sections should be joined not end to end, but overlapping, otherwise the crack will appear right here. At the corners, it should be folded so that it covers the corner edge. Only on top of it can the reinforcing corner be placed. In any case, double reinforcement is required in window openings; additional diagonal strips of mesh are applied at the corners. After the glue that holds the reinforcing mesh has dried, you can begin the plastering process. Using a wide spatula, the same glue that holds the mesh is applied to it in an even, thin layer. All irregularities after drying must be leveled with an abrasive float. Only after this can you begin to apply the finishing plaster layer, which is usually decorative. Thus, almost everyone can insulate the walls of a house with foam plastic slabs with their own hands. If all recommendations are followed, the result will be quite decent.

Layout diagram of fasteners for foam plastic.The process of insulating external walls with foam plastic involves a combined method of fastening. First, the material is glued to the wall surface, and then fastened with umbrella-type dowels. If you neglect one of these procedures, the quality of the coating will suffer so much that after a year it will have to be fastened again. To begin with, a metal profile is fastened with dowels at a distance of 50-60 cm from the ground surface and leveled with a level. The first row of foam plastic slabs is laid on it, this will ensure even laying of all subsequent ones. Cement-based glue is applied to one of them in heaps in 3 rows of 4-5 points, the slab is pressed tightly against the wall. The procedure is very similar to laying tiles. However, in the case of foam plastic, the seams are staggered not for the strength of the insulation itself, but to prevent cracks in the plaster that will cover it in the future. Unlike tiles, it is cut very easily with a bag knife. This arrangement is especially important at the corners, where the risk of cracks is highest. Using a plumb line, the alignment of the plane of each row is controlled. After the glue has slightly set, about a day later, 5 umbrella dowels are screwed into the center and corners of each plate. It should be remembered that you cannot leave the walls covered with foam plastic for a long time. Ultraviolet rays begin to destroy it, so immediately after final fastening it must be covered with plaster. Before applying the plaster, a reinforcing fiberglass mesh must be fixed to the insulation, since the walls made of foam plastic without it will not have a strong bond with the plaster layer. It is attached with a special reinforcement glue, which is produced by the same company "Ceresit". The surface of the foam plastic plates is smeared with a continuous thin layer of glue, and the mesh is pressed into it. Excess glue streaks must be removed immediately with a spatula. The side edges of the mesh sections should be joined not end to end, but overlapping, otherwise the crack will appear right here. At the corners, it should be folded so that it covers the corner edge. Only on top of it can the reinforcing corner be placed. In any case, double reinforcement is required in window openings; additional diagonal strips of mesh are applied at the corners. After the glue that holds the reinforcing mesh has dried, you can begin the plastering process. Using a wide spatula, the same glue that holds the mesh is applied to it in an even, thin layer. All irregularities after drying must be leveled with an abrasive float. Only after this can you begin to apply the finishing plaster layer, which is usually decorative. Thus, almost everyone can insulate the walls of a house with foam plastic slabs with their own hands. If all recommendations are followed, the result will be quite decent.