Carrying out repairs with walls islaborious and lengthy stage of finishing, which includes: cleaning walls, plaster, puttying, priming, wallpapering or the use of decorative plaster with subsequent painting.  So that during the gluing of the wallpaper there are no difficulties with irregularities and potholes, the walls must be pre-treated with putty. One of the main finishing processes is.

So that during the gluing of the wallpaper there are no difficulties with irregularities and potholes, the walls must be pre-treated with putty. One of the main finishing processes is.

What putty putty the walls before gluing the wallpaper?

Given that the skills in conductingplastering works are few, it is necessary to abandon the independent preparation of a mixture for puttying and resort to the use of industrial compounds that have different composition, taking into account their application in rooms where the coatings can absorb moisture, there are various temperature changes in the air mass in the building where repairs are carried out. Putty - a mixture of building materials, which in consistence is in the form of pasty mass or a powdery free-flowing substance. Applying this material before finishing the surfaces with wallpaper, you can remove the butt seams, straighten the unevenness of the walls, creating an ideal plane for subsequent work related to wallpapering. There is one drawback of the ready putty before the mixture, prepared independently: this is the price. As a result, the question arises, what kind of putty to finish the walls. In the case of small construction works on repairing walls, you need to use a ready mix, otherwise use dry mixes. Back to contents</a>

Steps for preparing the putty

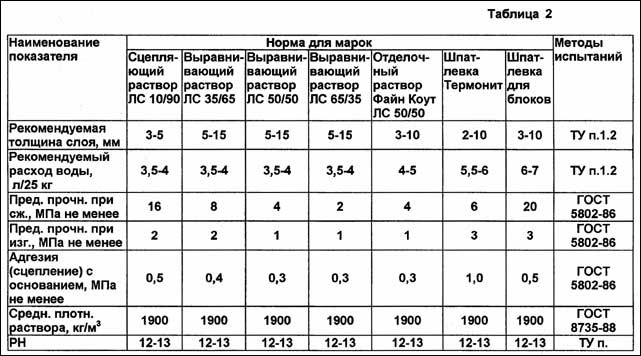

Table characteristics of putty solutions. Conduct a survey of the wall surface. When detecting major integrity violations, a plaster solution consisting of 3 parts sand and 1 part cement is used. After this, work is carried out related to the priming of the working surface, in order to create a strong connection between the wall and the applied solution. There are several kinds of putty:

Table characteristics of putty solutions. Conduct a survey of the wall surface. When detecting major integrity violations, a plaster solution consisting of 3 parts sand and 1 part cement is used. After this, work is carried out related to the priming of the working surface, in order to create a strong connection between the wall and the applied solution. There are several kinds of putty:

With such a rich list of materials, makethe choice of which putty putty the walls, is not easy. How to use it correctly? It should be borne in mind that the methods of applying putty on the walls are individual, although they have a number of requirements that are the same for all.  Tools for puttying. For work related to the puttying of walls, you will need:

Tools for puttying. For work related to the puttying of walls, you will need:

- priming fluid, for initial processing (starting), for the final stage (finishing);

- 3 types of spatula (angular, narrow, wide);

- paper with glued abrasive material (emery);

- mixer for stirring;

- bucket;

- water.

The mixing ratio of water and water, as a rule,is prescribed by the manufacturer. The process of preparation of the plaster takes about 6-7 minutes, taking into account that the mixture, when outdoors, quickly hardens. Proceeding from this, it is necessary to prepare the mixture in small volumes. The main tool for plastering is a spatula, which must be made of steel that is not susceptible to oxidation. The starting putty is applied in a thick layer in order to remove wall defects. Finish plaster is applied in a small layer. Each subsequent stage of puttying is carried out only after the previous layer has dried and its preliminary sanding with sandpaper. Puttying is made with a large spatula, which is applied in a small amount with a small spatula. When puttying plasterboard joints from gypsum board, it is necessary to glue the reinforcing mesh to the joints, then apply a layer of putty on it. Attention! Plastering the walls of gypsum board is necessary twice with the finishing putty, as the dismantling of pasted wallpaper will pass without damaging the walls. After finishing the coating, it is necessary to treat all surfaces with a special wallpaper glue. So, deciding which putty putty the walls before pasting them with wallpaper, you can start work.