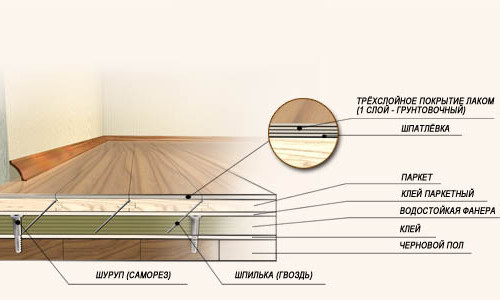

The quality of the floor is influenced by several factors.Firstly, the correct installation, secondly, the choice of flooring. But in order to ensure reliability, the floor must be properly prepared, which means that it should not have defects. For this purpose, it is leveled. There are many ways to eliminate this problem, but leveling the floor with plywood without joists is especially popular. Scheme of finishing the floor with plywood without joists.

Scheme of finishing the floor with plywood without joists.

How to choose plywood for leveling

This material has a large numberpositive qualities. But in order for plywood to fulfill its purpose, it must be chosen correctly. First of all, it is necessary to determine the direction of the fibers: longitudinal or transverse. In the first case, the fibers are located along the length of the entire material, and in the second - along the width. This point is taken into account when leveling the floor so that they lie against the main movement. Table of characteristics of different types of plywood. Plywood is also selected according to its intended purpose:

Table of characteristics of different types of plywood. Plywood is also selected according to its intended purpose:

- for construction, this is the alignment of the floor;

- industrial, can approach for such purposes, but on quality it concedes the first;

- packing;

- for furniture;

- structural.

Depending on the room in which the floor will be leveled, attention should also be paid to the moisture resistance of the material:

- FBA is an environmentally friendly type of plywood, suitable for decorating living rooms, but its moisture resistance level is low;

- FC - average level of moisture resistance, but direct contact with water is undesirable;

- FSB - high moisture tolerance;

- FB - due to impregnation with bakelite varnishhas a very high resistance to aggressive environments, but this is also a disadvantage, since harmful substances begin to be released on the underfloor heating system, which is not entirely safe for the health of residents;

- BS - special treatment allows this type to be used in yachts, but it is not suitable for leveling the floor with plywood;

- BV is the same plywood as BS, only its moisture tolerance is slightly worse.

Before leveling the floor with or without joiststhem, you should carefully study the technology. This will help you decide on the type of material that will be easier to work with. One of the stages of leveling is surface sanding. But modern manufacturers produce products that can reduce this moment. And all because plywood can be unsanded (NSh), sanded on one (Sh1) or both (Sh2) sides. Return to contents</a>

We prepare the floor for leveling the floor

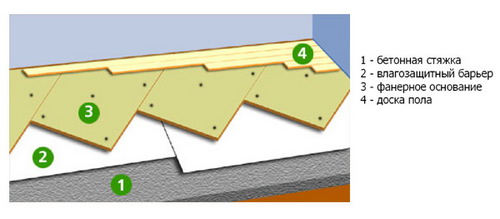

Sequence diagram of installation of adjustablefloor. Before laying the flooring, the subfloor should be leveled. For this, wet screed or plywood is used. But the second method is much simpler and more convenient. Plywood screed can be made bound or floating. In the first case, it will be a monolithic structure with the base itself, and in the second - no. With a bound screed, the material is fixed to the base with screws or nails, while the floating one is adapted to the joists. There is a material marking that indicates the grade: 1, 2, 3 and 4. If the work is carried out with an external coating, then the first grade will be used, since it does not have any defects on the surface, and during work it is only necessary to sand and varnish. For rough work, the second and third grades are used. Return to the table of contents</a>

Sequence diagram of installation of adjustablefloor. Before laying the flooring, the subfloor should be leveled. For this, wet screed or plywood is used. But the second method is much simpler and more convenient. Plywood screed can be made bound or floating. In the first case, it will be a monolithic structure with the base itself, and in the second - no. With a bound screed, the material is fixed to the base with screws or nails, while the floating one is adapted to the joists. There is a material marking that indicates the grade: 1, 2, 3 and 4. If the work is carried out with an external coating, then the first grade will be used, since it does not have any defects on the surface, and during work it is only necessary to sand and varnish. For rough work, the second and third grades are used. Return to the table of contents</a>

Floor leveling without lags: recommendations

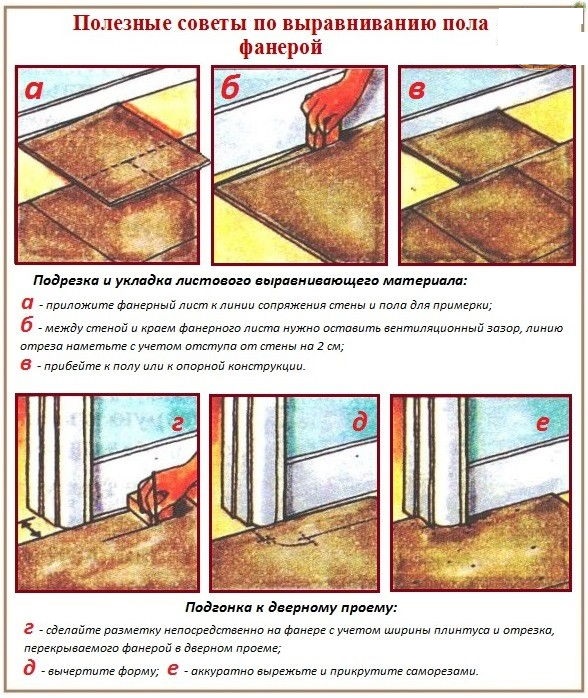

To level a floor with plywood without joists, you don’t need to do any special work or perform any special tasks. Recommendations for leveling the floor with plywood. To secure the sheets, you can use the following methods:

Recommendations for leveling the floor with plywood. To secure the sheets, you can use the following methods:

- glue;

- regulation.

For the first method of leveling the floor with plywooda special adhesive solution is used. But it is intended for those cases when there is a screed on the floor, and the differences are small. But there is a peculiarity here: the screed must be dry so that the humidity is minimal. To determine this nuance, the surface is covered with a film and pressed along the edges. Accordingly, if condensation forms inside, then the moisture has not yet evaporated, and if not, then you can start working. The adjustable method has a more complex technology, so it is not popular. It is best to use adjustment racks to level the floor. In this case, wooden blocks are mounted underneath, and then the plywood is laid in two layers. The thickness of the first will be 0.2 cm, and the second - a little less. Such a design is not afraid of heavy loads. In addition, it is always possible to dismantle the boring coating and replace it with a new one. The floor is leveled with plywood in cases where it is planned to lay laminate. This provides good ventilation and vapor permeability, which allows you to extend the life of the coating. Return to Contents</a>

Carrying out the work and the necessary tools

Tools that will come in handy when leveling the floor:

- electric jigsaw;

- building level;

- pencil;

- Ruler;

- glutinous solution;

- plywood.

The foundation can be made of planks or concrete.The boards are attached with a gap of 2-3 mm, and 2-3 cm should be left to the wall. In the first case, they should be additionally attached not only with glue, but also fixed with screws. And in the second case, waterproofing should be a must. Scheme of fastening plywood to a concrete base. If the work is to be done with the first type, then the following technologies can be used:

Scheme of fastening plywood to a concrete base. If the work is to be done with the first type, then the following technologies can be used:

- when the logs are not used;

- with the installation of belt supports;

- with lags.

The first technology involves fastening the plywoodto the floor surface using adhesive mortar. As for the second method, it is worth working hard, since the plywood will be attached to self-adjusting tape supports. In order to create them, you need studs that will be screwed into the floor. Next, screw several nuts with washers on top, which are designed to support the plywood. When the studs are installed along the entire perimeter, the sheets are mounted on top of them, and using a wrench, they are fixed at the required level. The third option with logs is intended for working with a floor that has significant differences in its surface. The first step is . Then plywood is mounted on top of them. This installation is convenient because it is possible to lay utility lines in the underground space. If the work is to be done with a concrete surface, then its preparation requires special attention. Unevenness provokes the appearance of a creak, since the sheets will constantly rub against each other. In addition, this defect significantly reduces the service life of the outer coating. For such cases, use:

- glue;

- lags.

To select one of these methods,it is necessary to determine what loads will be applied to the floor. But it is best if plywood sheets with a thickness of 1.6-2 cm are used. In the case of thinner material, it will be necessary to lay it in a double layer, and it is important that the lower one is thicker than the upper one. Return to the table of contents</a>

A few practical tips

It is not difficult to level the floor with plywood.Besides, such work will not take much time. The only thing that can take a lot of time is drying the screed, which on average takes about a week to dry completely so that it can be worked with.</ ul> </ ul>