In order to lay new flooring,It is very important to carry out high-quality preparatory work. Ultimately, a smooth and even base must be prepared. Otherwise, unpredictable, unpleasant moments may arise. Floor screed device diagram.One of the common problems that owners face during repair work is an uneven floor with various differences. Also, there may be various dents, cracks or bumps on the surface. In order to , you can use various methods. The most common option is to level the floor with a self-leveling mixture. It is very important to calculate the consumption of material that will be needed to level the floor. Self-leveling mixture can correct certain defects. By following all the recommendations, you can get a good finished result.

Floor screed device diagram.One of the common problems that owners face during repair work is an uneven floor with various differences. Also, there may be various dents, cracks or bumps on the surface. In order to , you can use various methods. The most common option is to level the floor with a self-leveling mixture. It is very important to calculate the consumption of material that will be needed to level the floor. Self-leveling mixture can correct certain defects. By following all the recommendations, you can get a good finished result.

The main varieties of mixtures for floor leveling

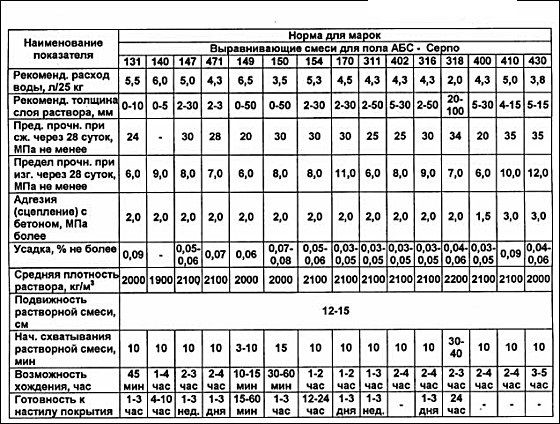

Technical characteristics of leveling mixturesfor floors. Self-leveling mixture refers to a solution whose consistency allows it to be easily distributed over the surface. Moreover, such a mixture fills all the irregularities and defects, ultimately forming a perfectly flat and smooth surface. You can level the floor with such a solution only if the defects are minimal. It is not recommended to use it with significant differences. The material consumption will depend on the area of the room in which the repair work is carried out and on the thickness of the intended layer. In order to calculate the material consumption, it is worth studying the information that manufacturers indicate on the packaging. In order to lay the floor covering on a strong, high-quality base, you should be very careful when choosing a self-leveling mixture. Today, the market offers a fairly large number of mixture options that are used in different cases. The floor leveling technology will depend on certain factors. The presented options can be divided into three main groups, which differ in the basics of the technology of use. Return to contents</a>

Technical characteristics of leveling mixturesfor floors. Self-leveling mixture refers to a solution whose consistency allows it to be easily distributed over the surface. Moreover, such a mixture fills all the irregularities and defects, ultimately forming a perfectly flat and smooth surface. You can level the floor with such a solution only if the defects are minimal. It is not recommended to use it with significant differences. The material consumption will depend on the area of the room in which the repair work is carried out and on the thickness of the intended layer. In order to calculate the material consumption, it is worth studying the information that manufacturers indicate on the packaging. In order to lay the floor covering on a strong, high-quality base, you should be very careful when choosing a self-leveling mixture. Today, the market offers a fairly large number of mixture options that are used in different cases. The floor leveling technology will depend on certain factors. The presented options can be divided into three main groups, which differ in the basics of the technology of use. Return to contents</a>

How to align the floor: the main points of the process

Scheme of preparatory work before .

Scheme of preparatory work before .

When choosing such a mixture, it is very important to pay attention not only to the method of use and variety, but also to the composition. Such compositions are produced today in two types:

- gypsum;

- cement.

The first option is characterized by the fact that they can beapply to the base with a fairly thick layer, up to 100 mm. But at the same time, the room should not be too humid, so it is not recommended to use it for bathrooms, swimming pools and kitchens. At the same time, it is very important to lay a layer of waterproofing before laying the floor covering. The second option can be safely used in any room, but it also has its limitations. The first such limitation is the layer thickness, it should not exceed 50 mm. Scheme of using self-leveling mixture.The mixture should be selected after the base has been preliminarily assessed. This type of leveling is not recommended for use on wooden surfaces or weak plank floors. For such a base, it is necessary to carry out preparatory work in advance and select a special type of solution. Different types of material have their own technical qualities and readiness times. On average, the poured surface will dry from several days to several weeks. Only after a certain period can the surface be used further. Manufacturers produce a product that dries much faster, it is used if the surface needs to be prepared in the shortest possible time. It is worth noting that the technical qualities of such mixtures are significantly reduced. Therefore, it is not recommended to use them for the reconstruction of a large floor area. Return to contents</a>

Scheme of using self-leveling mixture.The mixture should be selected after the base has been preliminarily assessed. This type of leveling is not recommended for use on wooden surfaces or weak plank floors. For such a base, it is necessary to carry out preparatory work in advance and select a special type of solution. Different types of material have their own technical qualities and readiness times. On average, the poured surface will dry from several days to several weeks. Only after a certain period can the surface be used further. Manufacturers produce a product that dries much faster, it is used if the surface needs to be prepared in the shortest possible time. It is worth noting that the technical qualities of such mixtures are significantly reduced. Therefore, it is not recommended to use them for the reconstruction of a large floor area. Return to contents</a>

Features of work with a self-leveling compound

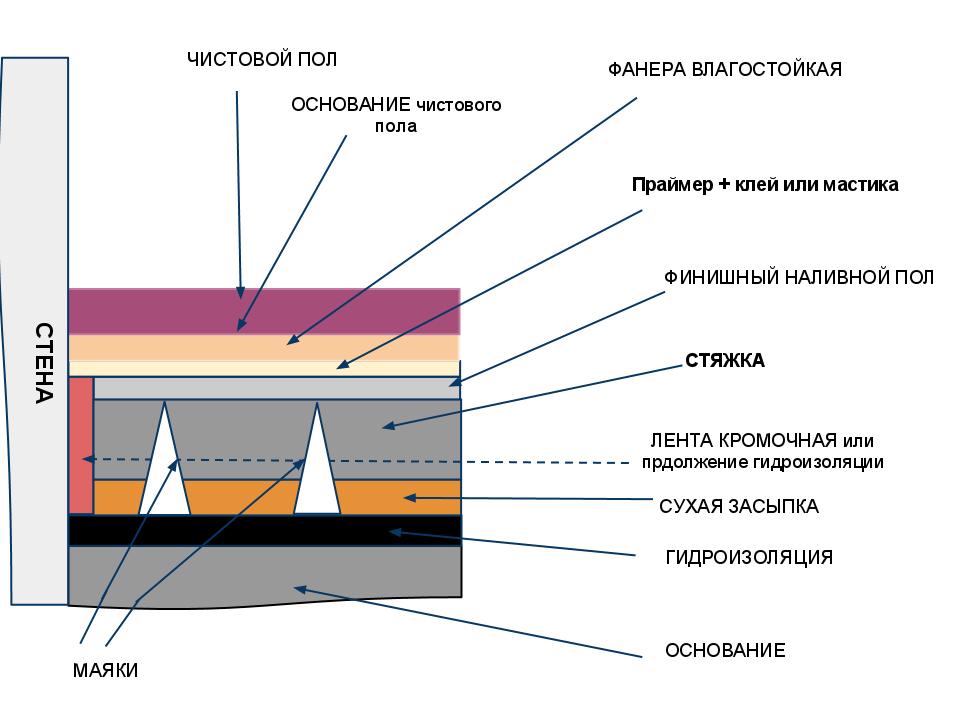

In order to prepare the base for laying decorative flooring, you need to have some experience. Leveling with a self-leveling mixture is a fairly simple process. Subfloor construction diagram oncombined screed. But in order to perform the work qualitatively, it is recommended to conduct trial work on a separate section, this will help to avoid errors. All work should be performed with an assistant, and if possible, more than one. This is due to the fact that the prepared solution loses its flowing properties after some time, so all work should be done as quickly as possible, while at a very high level. Another point of such work is that the floor must be leveled in one go. Joints in this case are unacceptable. Places where joints can be formed are characterized by lower strength. Inventory that is necessary to perform the work:

Subfloor construction diagram oncombined screed. But in order to perform the work qualitatively, it is recommended to conduct trial work on a separate section, this will help to avoid errors. All work should be performed with an assistant, and if possible, more than one. This is due to the fact that the prepared solution loses its flowing properties after some time, so all work should be done as quickly as possible, while at a very high level. Another point of such work is that the floor must be leveled in one go. Joints in this case are unacceptable. Places where joints can be formed are characterized by lower strength. Inventory that is necessary to perform the work:

- capacity in which the solution will be prepared;

- a construction mixer or a special drill bit;

- Spatula, with which the surface will be leveled;

- Needle roller, with which air bubbles are eliminated from the screed.

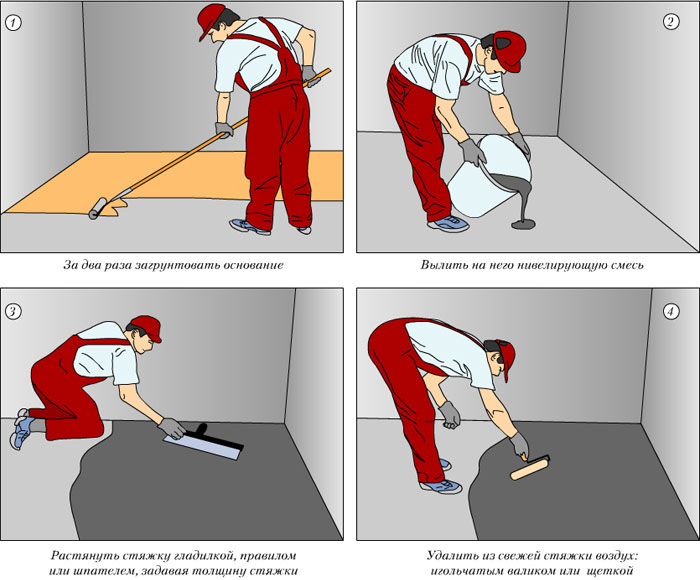

It is very important to prepare the surface beforepouring a self-leveling mixture. It should be free of dust and debris, and it is also worth removing greasy stains that can worsen adhesion. If this work is not done, then the screed may peel off in the future. Such a screed can be used if the surface differences do not exceed 2-3 cm, and there is no significant damage. Before pouring the screed, the base must be primed and wait until the layer dries completely. It is thanks to the primer that the mixture will lie much smoother, and the end result will be much better. In order to prepare a high-quality solution, it is very important to study the instructions on the packaging. It is their observance that will make it possible to obtain the necessary consistency of the solution. It is important to understand that a large amount of water in the solution makes it possible to level the surface much easier, but the screed will almost completely lose its qualities. A thick composition will be more difficult to level. Dry material must be poured into water, the reverse sequence can lead to the formation of lumps that will not allow you to get a perfectly smooth surface. The prepared solution must be used within 30 minutes, some types can retain their qualities a little longer, after which the solution is not recommended for use. Return to contents</a>

Solution casting: recommendations

When two people are involved in pouring,the work is divided as follows - one prepares the solution, the second does the pouring. If necessary, level the surface with a medium-sized spatula or a rule. In order to remove air from the solution, it is worth running a roller with spikes over the surface. Pouring the solution begins from the far corner. Part of the mixture is poured in one place and leveled if necessary, while it is worth preparing the next portion almost immediately. Ideally, the entire room should be poured in one go. This will prevent the formation of joints. The time of complete drying depends on the thickness of the screed, the composition and type of the mixture. During drying, it is worth maintaining a stable temperature and humidity in the room, sharp changes can negatively affect the quality of the finished result.</ ul>