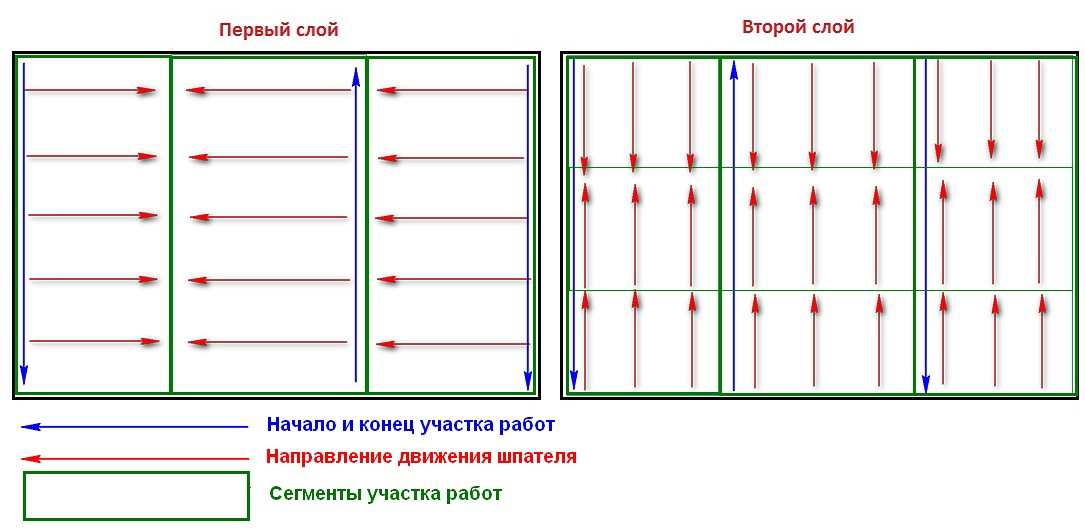

Almost any person who has carried outrepair work in the premises, it was necessary to level the walls. The need to organize such work appears at the moment when it is necessary to create a perfectly flat surface. For example, to prepare the base for painting or gluing wallpaper. Do-it-yourself wall leveling with putty will allow you to solve such problems. Such work is associated with passing several stages, which anyone can perform. The recommendations below will allow you to cope with the work clearly and systematically, avoiding mistakes and errors. Scheme of correct surface puttying.Usually, wall leveling is carried out on small areas, using ready-made compounds or self-made from a dry mixture. Such work cannot be done if the following tools are not available:

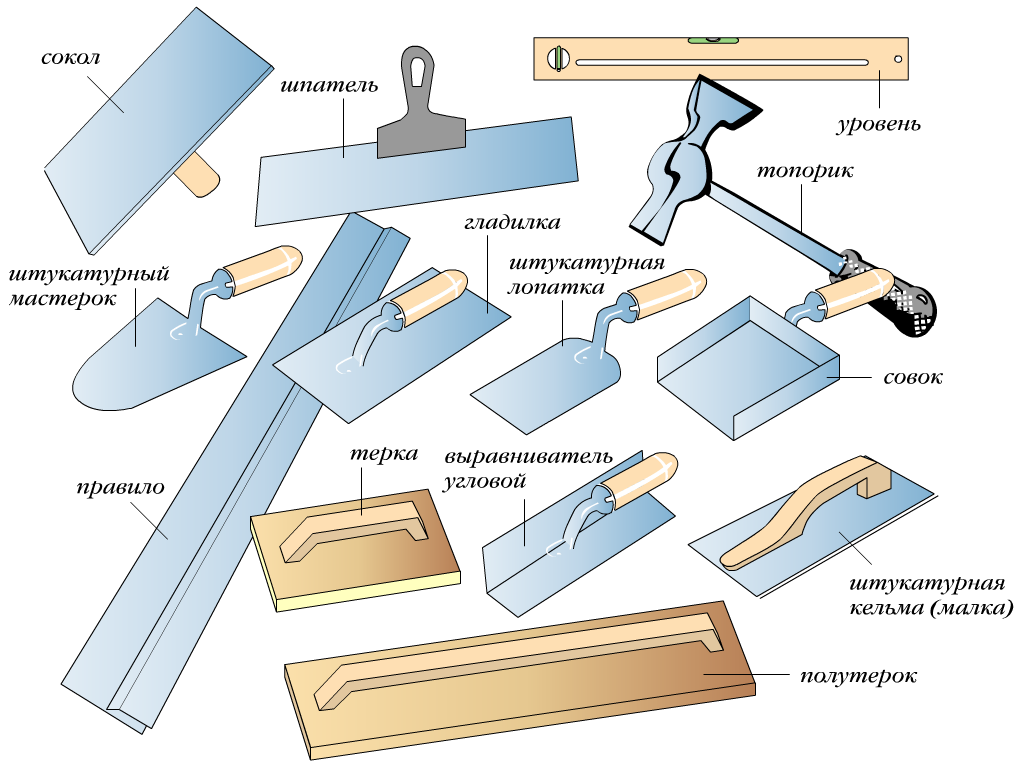

Scheme of correct surface puttying.Usually, wall leveling is carried out on small areas, using ready-made compounds or self-made from a dry mixture. Such work cannot be done if the following tools are not available:

- gypsum plaster;

- spatula of large and small size, including angular;

- grinding grater;

- roller for priming the surface;

- rule;

- drill with a mixer;

- capacity for spreading putty.

Preparatory work

Do-it-yourself wall alignment is inseparableis related to the preparation of the base. Thus, brick floors are puttied only after applying plaster to the surface; for concrete surfaces, such work is irrelevant. Tools for leveling walls.If there are traces of finishing coatings left on the partitions in the room, they should be removed. Cleaning measures are not particularly difficult. Old wallpaper on the base, a layer of water-based paint or gypsum plaster are washed off in the same way. The surface is treated with water in a small amount, after which it is scraped off with a spatula. If the canvases are processed in full size, then other types of coatings are moistened in small areas. As the putty absorbs moisture, it is easily cleaned off. If acrylic or alkyd paint was previously applied to the ceiling, you will have to work hard. The old layer of enamel is removed from the surface with a special agent. In another version, the paint is knocked off with an ordinary hammer. Return to the table of contents</a>

Tools for leveling walls.If there are traces of finishing coatings left on the partitions in the room, they should be removed. Cleaning measures are not particularly difficult. Old wallpaper on the base, a layer of water-based paint or gypsum plaster are washed off in the same way. The surface is treated with water in a small amount, after which it is scraped off with a spatula. If the canvases are processed in full size, then other types of coatings are moistened in small areas. As the putty absorbs moisture, it is easily cleaned off. If acrylic or alkyd paint was previously applied to the ceiling, you will have to work hard. The old layer of enamel is removed from the surface with a special agent. In another version, the paint is knocked off with an ordinary hammer. Return to the table of contents</a>

Sequence of work

Scheme for preparing putty.

Scheme for preparing putty.

Return to Contents</a>

Alignment of walls with plaster

Wall puttying scheme.The process of leveling walls with plaster is more complicated. Despite this, the surface is perfectly smooth and serves for a long period. Usually, such activities are designed for people who already have experience in such activities. Before carrying out the main work, furniture and things should be removed from the premises, otherwise they will become very dirty. To organize fruitful work, it is necessary to prepare a number of devices:

Wall puttying scheme.The process of leveling walls with plaster is more complicated. Despite this, the surface is perfectly smooth and serves for a long period. Usually, such activities are designed for people who already have experience in such activities. Before carrying out the main work, furniture and things should be removed from the premises, otherwise they will become very dirty. To organize fruitful work, it is necessary to prepare a number of devices:

- brush;

- level;

- Master OK;

- putty knife;

- rule;

- notched trowel;

- grater;

- capacity;

- gloves;

- a drill with a nozzle;

- hydro level;

- roulette.

Alignment of walls with plaster begins withthorough cleaning of the base from old types of finishing. The plane is washed and primed. Correct and thorough preparation will be the success of the subsequent actions. The plaster will not separate from such a surface. Then you need to take the tools and stock up on beacons. They will allow you to correctly determine the base of the future walls. The length of the rule used is 2 m. The height of the applied layer at all points can vary significantly. Thus, it can be from 1 mm to 4 cm or more. Then you will have to spend a large amount of solution. Return to the table of contents</a>

Use in the work of beacons

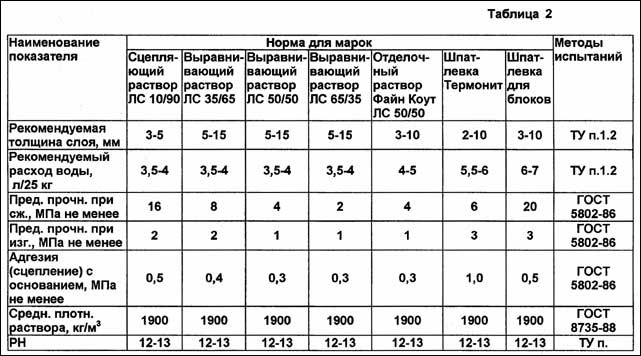

Table of characteristics of putty solutions.Beacons are vertical slats that define the base of future coatings. They serve as a guide for the rule and allow you to lay the composition on the surface. Such a device should be installed very carefully, since this event is considered the most important. The placement of beacons determines the geometry of future coatings. Mistakes in this matter are unacceptable. First, the lines are stretched horizontally at a distance of 0.5-3 cm from the surface of the coating. They are fixed with nails in the corners of the room. The stretched threads are placed in a vertical plane parallel to each other. A plumb line will help determine the evenness of such a structure. Beacons are determined in a position under the stretched threads. Such elements are placed vertically, slightly touching the threads. The beacon is attached to the partition with putty and dowels. After it is fixed, the rule is applied, it allows you to identify possible irregularities. After this, other beacons can be installed. The optimal distance between them will be 1 m. This distance will allow you to achieve perfectly smooth surfaces. Return to the table of contents</a>

Table of characteristics of putty solutions.Beacons are vertical slats that define the base of future coatings. They serve as a guide for the rule and allow you to lay the composition on the surface. Such a device should be installed very carefully, since this event is considered the most important. The placement of beacons determines the geometry of future coatings. Mistakes in this matter are unacceptable. First, the lines are stretched horizontally at a distance of 0.5-3 cm from the surface of the coating. They are fixed with nails in the corners of the room. The stretched threads are placed in a vertical plane parallel to each other. A plumb line will help determine the evenness of such a structure. Beacons are determined in a position under the stretched threads. Such elements are placed vertically, slightly touching the threads. The beacon is attached to the partition with putty and dowels. After it is fixed, the rule is applied, it allows you to identify possible irregularities. After this, other beacons can be installed. The optimal distance between them will be 1 m. This distance will allow you to achieve perfectly smooth surfaces. Return to the table of contents</a>

How to apply the mixture correctly: recommendations

It is convenient if two people will be plastering the walls at onceperson. One of them prepares the composition, and the other levels it with a rule. A steel ladle is used to process the base. With its help, the composition is easily removed from the container and simply thrown onto the surface. You can level the wall with a spatula. Using a rule, a line is drawn between the beacons, it helps to make the coating perfectly smooth. All partitions in the room are covered in this way. A room with an area of 12 square meters can be processed within 6 hours if the master has experience in plastering surfaces. After applying the layers, they need to dry well for 3 days. During this time, there should be no drafts in the room. The air temperature should be constant. Partitions can be puttied 7 days after applying the plaster layer.</ ul>