Laminate board is a product thatimitates natural wood flooring. It is made from natural wood, the front part is made of durable plastic. does not have any difficulties, almost anyone can handle the job, but proper preparation is necessary. Due to its wear resistance, durability,easy installation, harmlessness and decent appearance, laminate is quite a popular floor covering today. The floor under the laminate should be level - this is a must. Otherwise, the laminate will easily break: there will be a creak, the floor surface will become wavy. The surface can deform, individual panels will protrude above each other. It is for this reason that it is initially necessary to carry out work on preparing the base. The floor is inspected, if there are any irregularities, they should be eliminated. Usually a concrete screed is made, but for a wooden base, repairs may well be required, including the replacement of individual elements or the installation of plywood flooring.

Due to its wear resistance, durability,easy installation, harmlessness and decent appearance, laminate is quite a popular floor covering today. The floor under the laminate should be level - this is a must. Otherwise, the laminate will easily break: there will be a creak, the floor surface will become wavy. The surface can deform, individual panels will protrude above each other. It is for this reason that it is initially necessary to carry out work on preparing the base. The floor is inspected, if there are any irregularities, they should be eliminated. Usually a concrete screed is made, but for a wooden base, repairs may well be required, including the replacement of individual elements or the installation of plywood flooring.

Advantages of laminate

The advantages of laminate include a wide range of colors, which allows you to implement any design solutions. Laminate boards have numerous advantages:

The advantages of laminate include a wide range of colors, which allows you to implement any design solutions. Laminate boards have numerous advantages:

But there are also disadvantages, the main one beingis susceptible to the negative effects of moisture. When water gets on the surface, the boards swell and become deformed. There are special varieties that are more resistant to moisture, but it is still not recommended to spill water on the floor. Return to contents</a>

Aligning the wooden base

What you need before laying laminate flooringIt is not difficult to level the floor using self-leveling mixtures, but you must follow the instructions. Wooden and concrete bases require preliminary leveling. Plywood is usually used for wooden floors. The sheets are nailed to the base, usually 2 layers are laid. If necessary, additional joists made of wooden boards are mounted on the floor under the laminate, and only after that the sheathing is carried out with plywood panels. You can also do insulation at the same time. The heat-insulating material is laid between the joists. Ordinary expanded clay is suitable for this, which is distinguished by its low cost and excellent quality. If there are irregularities, the optimal method is leveling using special mixtures, which are also called self-leveling. The cost of the dry mixture is small, but the quality is high, the surface is smooth, perfectly suitable for finishing with laminate. It is not so difficult to use such a mixture, for this the following work is carried out:

What you need before laying laminate flooringIt is not difficult to level the floor using self-leveling mixtures, but you must follow the instructions. Wooden and concrete bases require preliminary leveling. Plywood is usually used for wooden floors. The sheets are nailed to the base, usually 2 layers are laid. If necessary, additional joists made of wooden boards are mounted on the floor under the laminate, and only after that the sheathing is carried out with plywood panels. You can also do insulation at the same time. The heat-insulating material is laid between the joists. Ordinary expanded clay is suitable for this, which is distinguished by its low cost and excellent quality. If there are irregularities, the optimal method is leveling using special mixtures, which are also called self-leveling. The cost of the dry mixture is small, but the quality is high, the surface is smooth, perfectly suitable for finishing with laminate. It is not so difficult to use such a mixture, for this the following work is carried out:

Return to Contents</a>

Methods of laying the laminate

Laminate flooring must be installed on a substrate,which performs insulating, soundproofing, leveling functions. To make a laminate floor, you must first select the installation method, and then prepare the following tools for the job:

Laminate flooring must be installed on a substrate,which performs insulating, soundproofing, leveling functions. To make a laminate floor, you must first select the installation method, and then prepare the following tools for the job:

- a hammer;

- electric jigsaw;

- cord;

- metal ruler and a simple pencil;

- building level;

- bar, which is necessary for laying panels;

- a special substrate for a laminate of the chosen type;

- laminate of the chosen class and type;

- clamp to fit the last row.

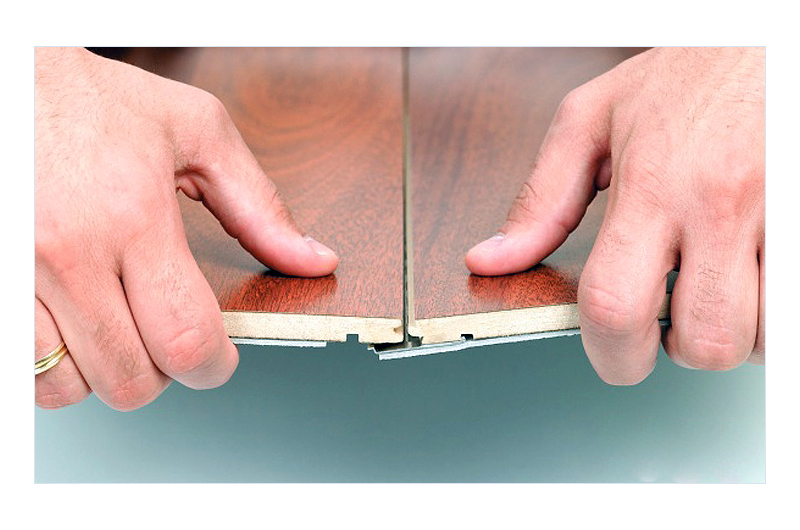

The installation process itself begins with the fact thatThe underlay is spread on the surface. This is a special material of small thickness. You can choose natural cork covering, foamed polyethylene, etc. Most often, polyethylene is used, which is distinguished by its low cost and good quality. You cannot lay 2 layers of underlay, it is better to immediately choose the required thickness. The optimal value is 4 mm, too thick underlay will cause the laminate to creak, its locks will fail. Some models have a spring profile onthe end faces of the laminated sheets, allowing the parts to be snapped together by light pressure without using glue. The underlay is laid simply, it is enough to roll the sheet out over the surface, slightly overlapping the walls. During installation, an overlap of 10 cm is observed, the joints are sealed with construction tape. The underlay must not be allowed to have breaks or other defects, as this will negatively affect the quality of the coating. After the base is ready, you can do the installation itself. The installation procedure may differ slightly depending on the type of surface chosen, but the technology remains the same. Today, the following installation methods are used:

Some models have a spring profile onthe end faces of the laminated sheets, allowing the parts to be snapped together by light pressure without using glue. The underlay is laid simply, it is enough to roll the sheet out over the surface, slightly overlapping the walls. During installation, an overlap of 10 cm is observed, the joints are sealed with construction tape. The underlay must not be allowed to have breaks or other defects, as this will negatively affect the quality of the coating. After the base is ready, you can do the installation itself. The installation procedure may differ slightly depending on the type of surface chosen, but the technology remains the same. Today, the following installation methods are used:

The 2nd method is most often used, when the lamellas are not only connected to each other, but also glued with a special compound for strength. Return to contents</a>

Laminate laying process

When installing laminate panels, make sure that the parts are in the direction of the light from the windows. The installation process is as follows:

When installing laminate panels, make sure that the parts are in the direction of the light from the windows. The installation process is as follows:

Laminate flooring is beautiful and stylishdesign option. Installation is easy to do yourself. To ensure that the coating is of high quality and durable, attention should be paid to leveling the base. For this, a screed or floor covering on the joists with plywood is used, after which the underlay is laid and the laminate is laid.