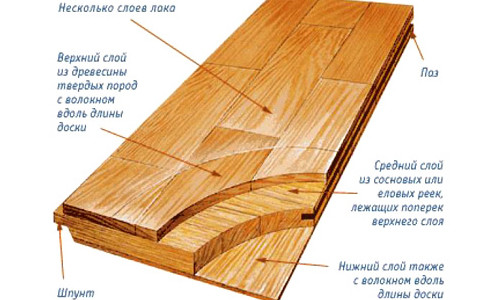

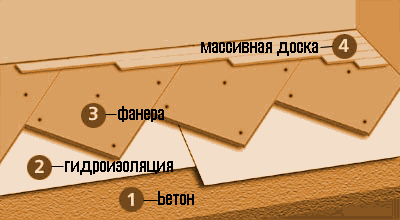

Solid wood board is the strongest material,from which the floor covering is made. Visually, it is similar to parquet board, but differs from it in structure, because it is completely made of wood. This raw material attracts with its practicality, durability, resistance to environmental influences. It is not afraid of loads, withstands more than one grinding. Scheme of the structure of solid wood boards.Laying solid wood flooring is a simple and practical way to creatively decorate a floor. It is advisable to do it at the final stage of repair work, after installing windows, leveling the floor (installing screed), and preparing the walls.

Scheme of the structure of solid wood boards.Laying solid wood flooring is a simple and practical way to creatively decorate a floor. It is advisable to do it at the final stage of repair work, after installing windows, leveling the floor (installing screed), and preparing the walls.

What is a massive board?

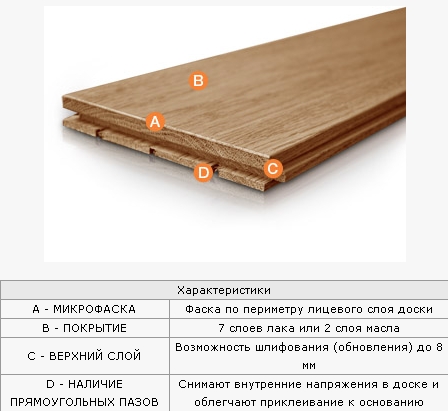

Tools for laying solid wood boards.Solid wood parquet boards have small ridges and grooves on the edges. Due to this, the floor sections are joined quickly and securely. The solid board is chamfered on the outer edge. After installation, the joints are separated by tiny gaps. Such a gap is necessary, because when various deformations occur, this distance is safely filled, and the floor remains unbent. On the back side, there is a series of longitudinal cuts and shallow transverse notches. They help reduce the load on the board and reduce the stress on the fibers, preventing them from being destroyed. The procedure for laying the solid board is carried out on a hard, strong, even, dry base. To prevent accidental damage to the finished parquet, you must first:

Tools for laying solid wood boards.Solid wood parquet boards have small ridges and grooves on the edges. Due to this, the floor sections are joined quickly and securely. The solid board is chamfered on the outer edge. After installation, the joints are separated by tiny gaps. Such a gap is necessary, because when various deformations occur, this distance is safely filled, and the floor remains unbent. On the back side, there is a series of longitudinal cuts and shallow transverse notches. They help reduce the load on the board and reduce the stress on the fibers, preventing them from being destroyed. The procedure for laying the solid board is carried out on a hard, strong, even, dry base. To prevent accidental damage to the finished parquet, you must first:

- to install ventilation, heating system;

- to wall the walls;

- install window packs.

Return to Contents</a>Criteria for choosing solid wood boards Characteristics of solid wood boards. In the process of manufacturing solid wood boards, various types of wood are used:

Characteristics of solid wood boards. In the process of manufacturing solid wood boards, various types of wood are used:

- European wood: alder, ash, walnut, larch, hornbeam, beech;

- exotic wood species: hevea, mesva, meranti, siam, karagacha, sucupira.

There are sets of floor coverings,made of suri, cherries, cherries and pears. These are capricious species. Therefore, it is necessary to ensure constant humidity monitoring, because light wood is afraid of "overdrying" and cannot be installed in rooms with high humidity. If the temperature and humidity change significantly, it is advisable to choose wood with a large amount of oils. These include oak, lapacho, merbau, cumaru. Red-brown color shades are present in such species as iroko, kamsha, afrosia. Traditionally, warm shades are inherent in rosewood, wenge, bog oak. When laying solid wood boards in corridors and hallways, it should be taken into account that in these rooms wood fibers experience a lot of stress. Therefore, it is necessary to install a floor made of hard domestic species here: oak, teak, ash. "Exotic" tree species will also do. Any tree species can be laid in guest rooms and bedrooms. Return to contents</a>

Ways to lay massive boards

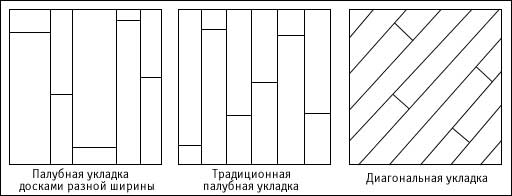

Types of laying solid wood boards.Laying solid wood flooring is the same as installing laminate flooring. Before laying solid wood flooring, unpack all packages and leave them indoors for a week to acclimatize. There are several options for laying solid wood flooring: The floor is placed on concrete floors. If the flooring is laid on concrete, the solid wood flooring must not be allowed to come into contact with the latter. Therefore, it is advisable to lay the wooden floor on a pad. Such pads can be made in several ways:

Types of laying solid wood boards.Laying solid wood flooring is the same as installing laminate flooring. Before laying solid wood flooring, unpack all packages and leave them indoors for a week to acclimatize. There are several options for laying solid wood flooring: The floor is placed on concrete floors. If the flooring is laid on concrete, the solid wood flooring must not be allowed to come into contact with the latter. Therefore, it is advisable to lay the wooden floor on a pad. Such pads can be made in several ways:

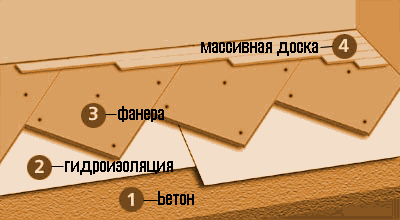

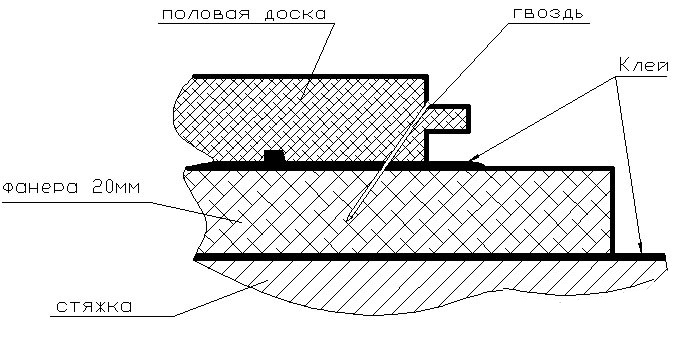

The surface is preliminarily treatedfinishing screed. After drying, it is checked for strength and carefully examined for damage. To check the degree of humidity of the base, holes are made in different sectors using a perforator. If the percentage of humidity exceeds the norm by more than 6%, a waterproofing film is laid on top of the screed. Scheme of laying solid wood boards on a plywood floor.The wooden floor is laid using a special glue designed for significant temperature differences. It can be used to fix heated floor coverings. Solid wood boards are mounted on plywood. In the local climate, the most popular method is to lay solid wood on a plywood base. Additional waterproofing is installed. First, the plywood sheets are cut into square or rectangular segments. The sections are diagonally placed on a layer of mastic or glue. Each piece is fastened with dowels (5-6 pieces per fragment). After this procedure, the floor is laid. The planks are fixed with two-component glue. Pneumatic studs are attached every three dozen centimeters along the side edge. The laid floor must be cleaned and lightly "sanded". If there are no comments on the assembly, then additional processing is not needed. If the technology is violated, the installation of solid wood boards will be of poor quality (contaminated screeds, not completely dried base, displacement of plywood sheets). This can deform the finished floor, and the fibers will change their color. The coating is laid on existing wooden coverings. The use of this method is justified only in cases where the technical condition of the old wooden floor is not in doubt.

Scheme of laying solid wood boards on a plywood floor.The wooden floor is laid using a special glue designed for significant temperature differences. It can be used to fix heated floor coverings. Solid wood boards are mounted on plywood. In the local climate, the most popular method is to lay solid wood on a plywood base. Additional waterproofing is installed. First, the plywood sheets are cut into square or rectangular segments. The sections are diagonally placed on a layer of mastic or glue. Each piece is fastened with dowels (5-6 pieces per fragment). After this procedure, the floor is laid. The planks are fixed with two-component glue. Pneumatic studs are attached every three dozen centimeters along the side edge. The laid floor must be cleaned and lightly "sanded". If there are no comments on the assembly, then additional processing is not needed. If the technology is violated, the installation of solid wood boards will be of poor quality (contaminated screeds, not completely dried base, displacement of plywood sheets). This can deform the finished floor, and the fibers will change their color. The coating is laid on existing wooden coverings. The use of this method is justified only in cases where the technical condition of the old wooden floor is not in doubt. Scheme of laying solid wood boards on concretescreed. When starting work, you should thoroughly examine the old base and carry out a number of preparatory works. An abrasive belt is placed in a belt sander. Then the surface is processed with this tool until the existing plane is maximally leveled and freed from previous paint layers. After sanding, the resulting surface must be thoroughly cleaned. When laying the solid board, you should adhere to the direction of the previous base. The existing floor, as in the previous version, is lined with plywood sheets, then the plywood rough layer is also sanded. "Floating method". In this case, there is no connection with the base. The board is attached separately. The solid wood planks are attached only to each other. The assembled parquet is able to cope with large mechanical loads and humidity changes precisely because the subfloor underneath is not connected to it in any way. This method should be used when it is supposed to install a "warm floor". Since climatic conditions can fluctuate, the dimensions of the boards change. To keep deformation to a minimum, the installation process is carried out using self-tapping screws with a protective anti-corrosion layer. The boards are attached to the staples. This method is classified as "floating", but here the installation of solid boards is half as cheap as the previous ones.

Scheme of laying solid wood boards on concretescreed. When starting work, you should thoroughly examine the old base and carry out a number of preparatory works. An abrasive belt is placed in a belt sander. Then the surface is processed with this tool until the existing plane is maximally leveled and freed from previous paint layers. After sanding, the resulting surface must be thoroughly cleaned. When laying the solid board, you should adhere to the direction of the previous base. The existing floor, as in the previous version, is lined with plywood sheets, then the plywood rough layer is also sanded. "Floating method". In this case, there is no connection with the base. The board is attached separately. The solid wood planks are attached only to each other. The assembled parquet is able to cope with large mechanical loads and humidity changes precisely because the subfloor underneath is not connected to it in any way. This method should be used when it is supposed to install a "warm floor". Since climatic conditions can fluctuate, the dimensions of the boards change. To keep deformation to a minimum, the installation process is carried out using self-tapping screws with a protective anti-corrosion layer. The boards are attached to the staples. This method is classified as "floating", but here the installation of solid boards is half as cheap as the previous ones. Solid wood board fastening diagram.Professional fastening of the board is carried out using aluminum brackets, to which silicone compensators are added. This ensures good strength of the joints of the planks at the ends. With some skills, the owner of the premises can assemble this structure on his own. Any smooth surface will do for this. A floor laid in this way has many advantages:

Solid wood board fastening diagram.Professional fastening of the board is carried out using aluminum brackets, to which silicone compensators are added. This ensures good strength of the joints of the planks at the ends. With some skills, the owner of the premises can assemble this structure on his own. Any smooth surface will do for this. A floor laid in this way has many advantages:

- very simple to mount;

- is environmentally friendly, since there are no impregnations, primers and adhesives;

- being stapled, is more resistant to mechanical influences;

- it is easily repaired: it is possible to change only the damaged segments, while the basic part of the laying remains untouched;

- almost does not deform, due to the fact that the array is not associated with the base floor covering.

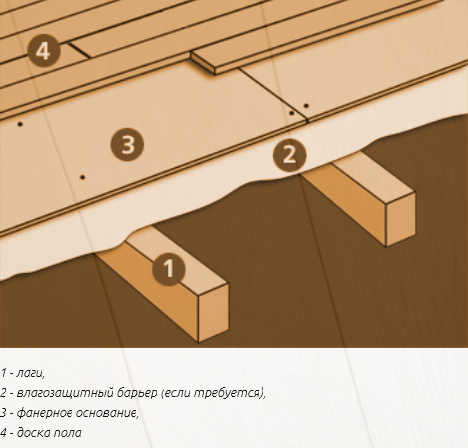

Fixing boards on joists - bars made ofwood. In most cases, solid wood flooring is installed during a major remodeling of a room. There are situations when it is necessary to quickly level the flooring without using cement mixtures. Logs made of timber are used if it is necessary to compensate for the difference in floor height or if small podiums are created, as well as various commercial premises. Scheme of laying solid wood boards on joists.Before starting the installation of log structures, it is necessary to cover the floor with waterproofing materials. Here, penofol or polyethylene sheets are used. The logs are laid out on opposite walls and fastened to the concrete screed with dowels, anchors or screws. If communications run inside the screed, then it cannot be drilled. Here, the use of special mastics or bitumen-containing solutions is justified. Then, every half meter, threads are pulled along which the logs are installed. The gaps between them are filled with insulating materials. Fiberboard panels are attached to the logs, and solid wood is laid on them. Assembly on an adhesive backing. The use of this method of laying solid wood boards became possible only after the appearance of a one-sided adhesive backing. This material has good thermal and noise insulation characteristics. The joints of the boards remain invisible, because the adhesive perfectly connects adjacent parts. With a backing, the wood board hardly swells. Neither glue nor staples are needed during installation. No additional foundation is required. The adhesive backing sheets are laid directly on the concrete, with the adhesive side facing up. After that, the solid board is laid on the finished flooring. Return to contents</a>In conclusion Taking into account all that has been saidIt can be noted: solid wood boards are durable and environmentally friendly. They retain sound and heat well. The service life of such coverings exceeds one hundred years, provided that the humidity in the room is not excessively high.

Scheme of laying solid wood boards on joists.Before starting the installation of log structures, it is necessary to cover the floor with waterproofing materials. Here, penofol or polyethylene sheets are used. The logs are laid out on opposite walls and fastened to the concrete screed with dowels, anchors or screws. If communications run inside the screed, then it cannot be drilled. Here, the use of special mastics or bitumen-containing solutions is justified. Then, every half meter, threads are pulled along which the logs are installed. The gaps between them are filled with insulating materials. Fiberboard panels are attached to the logs, and solid wood is laid on them. Assembly on an adhesive backing. The use of this method of laying solid wood boards became possible only after the appearance of a one-sided adhesive backing. This material has good thermal and noise insulation characteristics. The joints of the boards remain invisible, because the adhesive perfectly connects adjacent parts. With a backing, the wood board hardly swells. Neither glue nor staples are needed during installation. No additional foundation is required. The adhesive backing sheets are laid directly on the concrete, with the adhesive side facing up. After that, the solid board is laid on the finished flooring. Return to contents</a>In conclusion Taking into account all that has been saidIt can be noted: solid wood boards are durable and environmentally friendly. They retain sound and heat well. The service life of such coverings exceeds one hundred years, provided that the humidity in the room is not excessively high.