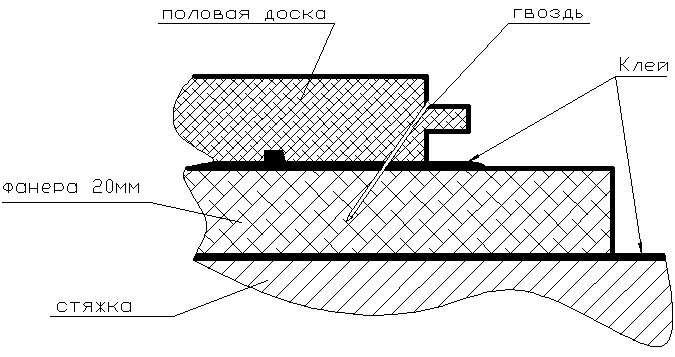

For the floor it is recommended to use naturalmaterials that are not only attractive, but also environmentally friendly, durable, resistant to heavy loads, abrasion. These properties have a massive board, which differs elegant and solid appearance, the highest strength. The laying of such a board is not difficult. With work to cope easier than with the laying of traditional parquet. Although a massive board and does not have the luxury of artistic parquet, but its appearance is more solid. Most often, laying a massive board on the screed, but not immediately on the concrete base, and on the lag or plywood coating.  Instructions for.Why is it so? The board is subject to temperature deformations and the negative effects of humidity, therefore it is not recommended to immediately lay it on concrete. But a layer of moisture-resistant plywood or floors on logs provide the necessary qualities. Thus, it turns out to level the base, to give it exactly the properties that are required by the installation technology. Such work involves additional costs, and more time is spent. If you lay the coating directly on the screed, you may encounter deformation of the boards, the formation of cracks, creaking and other negative factors.

Instructions for.Why is it so? The board is subject to temperature deformations and the negative effects of humidity, therefore it is not recommended to immediately lay it on concrete. But a layer of moisture-resistant plywood or floors on logs provide the necessary qualities. Thus, it turns out to level the base, to give it exactly the properties that are required by the installation technology. Such work involves additional costs, and more time is spent. If you lay the coating directly on the screed, you may encounter deformation of the boards, the formation of cracks, creaking and other negative factors.

Hardboard options

Types of fastening of parquet boards. completely differently, you can choose the best option. There are many options for such styling:

Types of fastening of parquet boards. completely differently, you can choose the best option. There are many options for such styling:

Back to contents</a>

Preparing the board for work

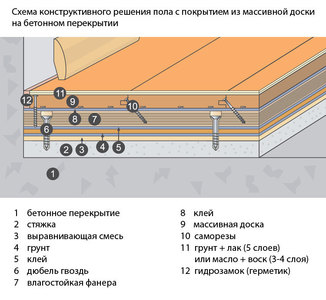

How to properly perform the work? Preparation of the coating involves working with the substrate. A massive board can not be laid directly on the concrete base, the screed must be covered with a layer, lags must be installed. Plywood directly on the screed is laid only in the case where there is no possibility to reduce the height of the ceiling. Usually this is typical of urban apartments. In this case, a layer of waterproofing is laid on the concrete, after which a moisture-resistant plywood is laid. Lags are more preferable, as they are more reliable, they perfectly protect the board from various negative phenomena, including deformations, cracking, drying out or swelling.  Arrangement of the floor on the logs. The floors on the logs are made in this way:

Arrangement of the floor on the logs. The floors on the logs are made in this way:

Back to contents</a>

Laying a massive board

Laying a massive board on the screed. After the logs are assembled and the finish of the finishing floor is completed, you can proceed to laying a massive board. You can use one of two methods - glue and lock method. It is necessary to clean the floor, dry it, check its horizontality before performing the work. After that, the surface is additionally treated with a special mastic, which gives the base water repellent properties. After that, the plywood must dry. The board is aged for about 4 days while the plywood dries. Do this in the room where it will be mounted. Keep the material in a horizontal position, under it you can lay the film. When the floor has dried, and the board has spent a lot of time, you can proceed with installation. On the back side of each board, a layer of glue is applied, after which it is firmly attached to the base. The second board is covered with an adhesive compound. It is necessary to snap the lock snugly, do this at an angle, after which the board is pressed against the surface of the base. Laying a massive board continues in the same way until the whole floor is covered. First lay whole boards, after cutting is performed, small pieces are laid. The glueless method involves laying directly on the surface, but without glue. This is done for the floors under the logs, the space between which can be filled with heaters. Such a floor turns out to be floating, i.e. A massive board is completely unrelated to the base. This method is most preferable, but everything depends on external conditions. Fastening is carried out due to the locking connection of the spike-groove. The board fits on the surface, after which the second at an angle is put into the groove, falls to the surface. The process itself is almost the same, but the glue is not used. Back to contents</a>

Laying a massive board on the screed. After the logs are assembled and the finish of the finishing floor is completed, you can proceed to laying a massive board. You can use one of two methods - glue and lock method. It is necessary to clean the floor, dry it, check its horizontality before performing the work. After that, the surface is additionally treated with a special mastic, which gives the base water repellent properties. After that, the plywood must dry. The board is aged for about 4 days while the plywood dries. Do this in the room where it will be mounted. Keep the material in a horizontal position, under it you can lay the film. When the floor has dried, and the board has spent a lot of time, you can proceed with installation. On the back side of each board, a layer of glue is applied, after which it is firmly attached to the base. The second board is covered with an adhesive compound. It is necessary to snap the lock snugly, do this at an angle, after which the board is pressed against the surface of the base. Laying a massive board continues in the same way until the whole floor is covered. First lay whole boards, after cutting is performed, small pieces are laid. The glueless method involves laying directly on the surface, but without glue. This is done for the floors under the logs, the space between which can be filled with heaters. Such a floor turns out to be floating, i.e. A massive board is completely unrelated to the base. This method is most preferable, but everything depends on external conditions. Fastening is carried out due to the locking connection of the spike-groove. The board fits on the surface, after which the second at an angle is put into the groove, falls to the surface. The process itself is almost the same, but the glue is not used. Back to contents</a>

Finishing Coating

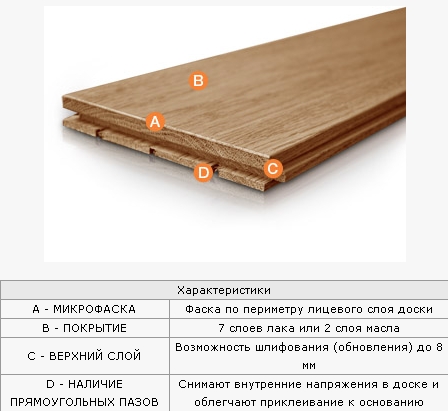

Characteristics of a massive board. After the stacking of the massive board is finished, you need to proceed to the finish work. For this, the surface is treated with a grinding machine, all dust is removed from the surface. Further work may consist of coating the boards with a layer of varnish, painting them or impregnating them with special oils. Everything depends on what is required from the coating. After the varnish has dried, a beautiful, glossy or matte finish is obtained. Apply the varnish in 2-3 layers, each of them must completely dry out. The varnish itself can be taken transparent or shaded. Everything depends on wood, the presence on it of a beautiful natural pattern. Before you can varnish the surface, you can use stain. This composition can give the wood any necessary shade. It perfectly protect wood from various negative influences. For example, from moisture, insects, rot. The stain is applied by brush or roller, enough 1-2 layers, but it all depends on what kind of effect is needed. After complete drying, you can start lacquering, enough of its two layers. A massive board can be impregnated with a special oil. This option is most preferable, as the wood gets a noble appearance. The cost of oils is usually quite considerable, lacquering is cheaper. To begin finishing finishing it is necessary approximately in day after the cover is completely ready. The consumption of lacquer is about 150 g for every 1 m², but it all depends on the composition, it must be paid attention. You can walk on the floor after 2 days, and more serious loads are possible not earlier than in a week. The massive board is distinguished by a stylish and solid appearance, which will give the room a certain charm. Laying of such flooring is not so difficult, most often it is mounted on logs. This provides the necessary conditions for wood, protects it from moisture, sharp temperature changes and expansions.

Characteristics of a massive board. After the stacking of the massive board is finished, you need to proceed to the finish work. For this, the surface is treated with a grinding machine, all dust is removed from the surface. Further work may consist of coating the boards with a layer of varnish, painting them or impregnating them with special oils. Everything depends on what is required from the coating. After the varnish has dried, a beautiful, glossy or matte finish is obtained. Apply the varnish in 2-3 layers, each of them must completely dry out. The varnish itself can be taken transparent or shaded. Everything depends on wood, the presence on it of a beautiful natural pattern. Before you can varnish the surface, you can use stain. This composition can give the wood any necessary shade. It perfectly protect wood from various negative influences. For example, from moisture, insects, rot. The stain is applied by brush or roller, enough 1-2 layers, but it all depends on what kind of effect is needed. After complete drying, you can start lacquering, enough of its two layers. A massive board can be impregnated with a special oil. This option is most preferable, as the wood gets a noble appearance. The cost of oils is usually quite considerable, lacquering is cheaper. To begin finishing finishing it is necessary approximately in day after the cover is completely ready. The consumption of lacquer is about 150 g for every 1 m², but it all depends on the composition, it must be paid attention. You can walk on the floor after 2 days, and more serious loads are possible not earlier than in a week. The massive board is distinguished by a stylish and solid appearance, which will give the room a certain charm. Laying of such flooring is not so difficult, most often it is mounted on logs. This provides the necessary conditions for wood, protects it from moisture, sharp temperature changes and expansions.