Liquid wallpaper contains particlescellulose, cotton, less often silk, adhesive and coloring matter. In accordance with the declared texture, mica pieces, glitter, flock, silk threads and other types of fillers can also act as additives. The mixture is represented by dry small flakes, soluble in water and forming a smooth or embossed coating on the surface with a layer thickness of 2-3 or 4-5 mm. Below we will tell you about the features of this type of wallpaper, the technology of application to various surfaces (plywood, fiberboard, chipboard, etc.). Liquid wallpaper contains particles of cellulose, cotton, sometimes silk, adhesive and dye.

Liquid wallpaper contains particles of cellulose, cotton, sometimes silk, adhesive and dye.

Advantages and disadvantages of liquid wallpaper

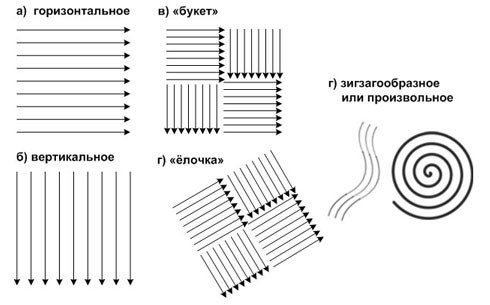

The coating called liquid wallpaper not only looks impressive, but also has positive characteristics that distinguish it from other materials for wall finishing. Let's consider these advantages: Liquid wallpaper application schemes.

Liquid wallpaper application schemes.

Return to Contents</a>

Technology of creating a coating with liquid wallpaper

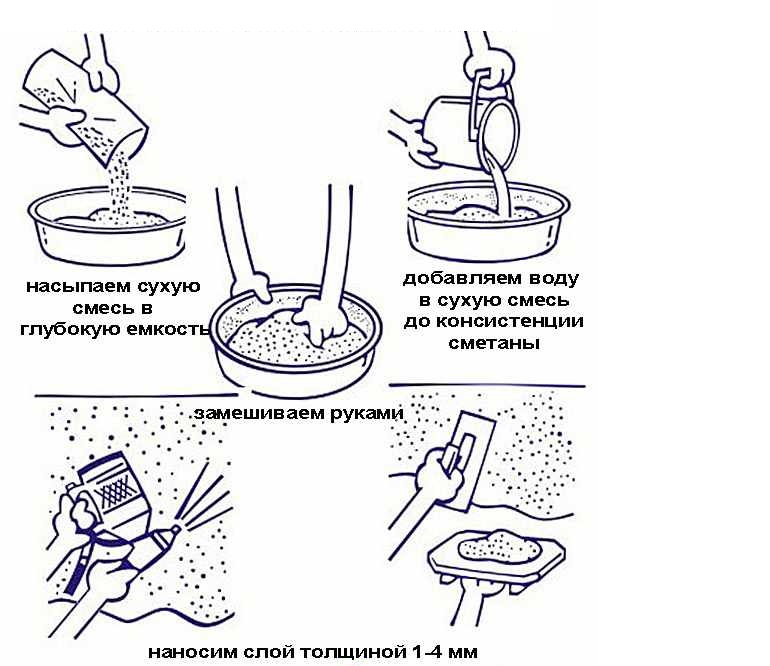

Stages of applying liquid wallpaper to fibreboard walls.The attractiveness of the finished coating will depend entirely on the application method and the tool used for these purposes. The mass is distributed over the surface using a trowel or a relief roller, although you can also use a special sprayer - a hopper gun. Having brought the composition to the desired density, it is quite possible to create molded decorative patterns and panels on the surfaces. If you want to change the color of the old liquid wallpaper, then simply apply a fresh solution. Liquid wallpaper can mask any unevenness of the surface. After all, the coating layer can be up to 1.0 cm thick. Before applying the composition, the surface requires mandatory preparation. Visible cracks must be putty. The old layer of whitewash must be removed. Then the surface is primed. Before applying the wallpaper, the wall must meet the requirements of cleanliness and dryness. When diluting the mixture with water, take into account the circumstance of what thickness the solution should be obtained in the end. Basically, the solution is prepared as follows: 1 part of the mixture is poured with 4 parts of water. To ensure that there are no unpleasant surprises in the future, follow the manufacturer's instructions when working. The base background is formed using a sprayer (or a spatula). After 6 hours, the wall is treated with a special textured roller. Its relief is selected based on the pattern you prefer to see in the end. Depending on the thickness of the layer, the consistency of the solution, and the humidity in the room, the drying period will be 12 hours - 3 days. The consumption of the mixture per 1 m2 of area will be approximately 0.6 liters (with a layer of 1-3 mm). The service life of the coating is up to 7 years. To make the coating moisture resistant, it is sometimes varnished. Yes, the wallpaper will stop absorbing odors and moisture, but they will lose one property - they will no longer be able to be ventilated (or "breathing"). Return to contents</a>

Stages of applying liquid wallpaper to fibreboard walls.The attractiveness of the finished coating will depend entirely on the application method and the tool used for these purposes. The mass is distributed over the surface using a trowel or a relief roller, although you can also use a special sprayer - a hopper gun. Having brought the composition to the desired density, it is quite possible to create molded decorative patterns and panels on the surfaces. If you want to change the color of the old liquid wallpaper, then simply apply a fresh solution. Liquid wallpaper can mask any unevenness of the surface. After all, the coating layer can be up to 1.0 cm thick. Before applying the composition, the surface requires mandatory preparation. Visible cracks must be putty. The old layer of whitewash must be removed. Then the surface is primed. Before applying the wallpaper, the wall must meet the requirements of cleanliness and dryness. When diluting the mixture with water, take into account the circumstance of what thickness the solution should be obtained in the end. Basically, the solution is prepared as follows: 1 part of the mixture is poured with 4 parts of water. To ensure that there are no unpleasant surprises in the future, follow the manufacturer's instructions when working. The base background is formed using a sprayer (or a spatula). After 6 hours, the wall is treated with a special textured roller. Its relief is selected based on the pattern you prefer to see in the end. Depending on the thickness of the layer, the consistency of the solution, and the humidity in the room, the drying period will be 12 hours - 3 days. The consumption of the mixture per 1 m2 of area will be approximately 0.6 liters (with a layer of 1-3 mm). The service life of the coating is up to 7 years. To make the coating moisture resistant, it is sometimes varnished. Yes, the wallpaper will stop absorbing odors and moisture, but they will lose one property - they will no longer be able to be ventilated (or "breathing"). Return to contents</a>

Frequently encountered questions about liquid wallpaper

Are they repairable?The ease of correcting defects on wallpaper is one of the undeniable advantages of the material. For example, cracks appeared on the surface after drying. All actions to correct this incident will be reduced to wetting the wallpaper with water and leveling. Is it possible on fiberboard, chipboard, OSB boards and plywood? Wall design options using liquidswallpaper on a fiberboard wall. The answer will be negative if the specified surfaces are not protected in any way. Without proper waterproofing, various complications are possible - a change in the structure of the base material, the appearance of stains on its surface, etc. That is, the participation of a professional is required in this case. If the boards have a laminated coating, then it is enough to cover it with a primer paint with the addition of abrasive crumbs (for example, "Ceresit CT 16"). This can achieve high-quality adhesion to the surface. If the boards are not laminated, then they are first covered with alkyd enamel, after which they are primed. There is insufficient information on how to apply liquid wallpaper to plywood. Some experts claim that if you do apply the wallpaper, you can get a warped plywood surface. In other words, the layer in direct contact with the liquid coating will slightly reduce its area. That is, the effect of "shagreen skin" will occur. And the plywood layer on the opposite side of the sheet will remain the same size. The thinner the layer of the plywood sheet, the more it will deform. Bending will be observed inward, from the side where the wallpaper is applied. It is also important to note the fact that plywood is still a multi-layer glued veneer, which does not accept contact with moisture. If you apply a liquid coating to plywood, you can expect the top layer to peel off. You can try applying liquid wallpaper to plywood impregnated with bakelite glue. However, this type of plywood is rare and expensive, and is used for shipbuilding and aircraft construction. If you have a burning desire, you can experiment by taking a thin sheet of plywood and applying liquid wallpaper to it. Wait a little and see what happens. Use innovative technologies in finishing, but be careful.

Wall design options using liquidswallpaper on a fiberboard wall. The answer will be negative if the specified surfaces are not protected in any way. Without proper waterproofing, various complications are possible - a change in the structure of the base material, the appearance of stains on its surface, etc. That is, the participation of a professional is required in this case. If the boards have a laminated coating, then it is enough to cover it with a primer paint with the addition of abrasive crumbs (for example, "Ceresit CT 16"). This can achieve high-quality adhesion to the surface. If the boards are not laminated, then they are first covered with alkyd enamel, after which they are primed. There is insufficient information on how to apply liquid wallpaper to plywood. Some experts claim that if you do apply the wallpaper, you can get a warped plywood surface. In other words, the layer in direct contact with the liquid coating will slightly reduce its area. That is, the effect of "shagreen skin" will occur. And the plywood layer on the opposite side of the sheet will remain the same size. The thinner the layer of the plywood sheet, the more it will deform. Bending will be observed inward, from the side where the wallpaper is applied. It is also important to note the fact that plywood is still a multi-layer glued veneer, which does not accept contact with moisture. If you apply a liquid coating to plywood, you can expect the top layer to peel off. You can try applying liquid wallpaper to plywood impregnated with bakelite glue. However, this type of plywood is rare and expensive, and is used for shipbuilding and aircraft construction. If you have a burning desire, you can experiment by taking a thin sheet of plywood and applying liquid wallpaper to it. Wait a little and see what happens. Use innovative technologies in finishing, but be careful.