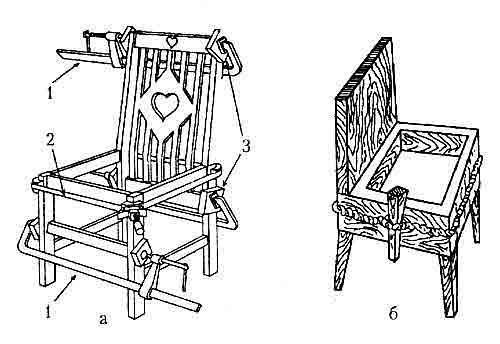

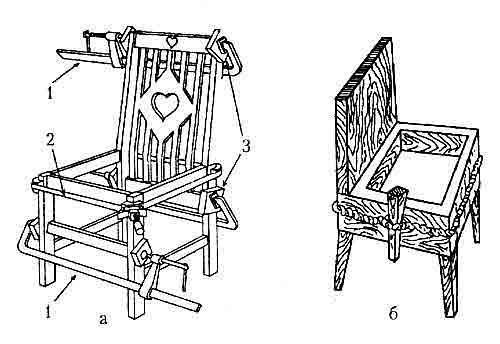

Carved furniture has always been popular,but its cost in stores is sometimes too high, especially if we are talking about a complex design. Having some experience working with natural wood, you can make unusually beautiful and stylish furniture for your own home with your own hands. Compression of chair joints during gluing:a - clamps and a belt tie, 1 - clamp, 2 - belt tie, 3 - a piece of timber or board, b - rope. Tables, chairs, armchairs, cabinets - all this is available for self-made. You only need skill, imagination and patience, since wood carving is a long and painstaking process. If you have no experience in doing such work, then you can start by making a small stool with carved legs. Gradually, you can move on to making tables, armchairs, carved panels for the room. The work must be done based on certain rules and requirements, choosing the type of carving that is most suitable.

Compression of chair joints during gluing:a - clamps and a belt tie, 1 - clamp, 2 - belt tie, 3 - a piece of timber or board, b - rope. Tables, chairs, armchairs, cabinets - all this is available for self-made. You only need skill, imagination and patience, since wood carving is a long and painstaking process. If you have no experience in doing such work, then you can start by making a small stool with carved legs. Gradually, you can move on to making tables, armchairs, carved panels for the room. The work must be done based on certain rules and requirements, choosing the type of carving that is most suitable.

Examples of carving for a chair

Wood carving can be traditional andextraordinary. The choice of a specific method depends on whether there is experience, what tools are available. The methods of decorating furniture items include: Figure 1. Drawing of a stool.

Figure 1. Drawing of a stool.

Through-thread, which is considered one of thesimple. Two methods are used: cutting thread when the sections are sawed, and slotted, when through holes are cut out by incisors or chisels. If you use a relief ornament, then this version of the through thread is called openwork.

Flat-notched carving.It has a flat background, and the decorative elements seem to go deep into it. There are many subtypes of this type of carving. Contour carving is popular, based on cutting grooves with a corner chisel or knives. Bracket carving is leaving a mark on wood in the form of a bracket. The ornament is unusual. Geometric carving is done in 2 stages. This is a drawing and trimming of the pattern, as a result, beautiful triangular patterns are obtained, they are diamonds, honeycombs, twists, auroras, chains, etc. Black varnish carving involves using a varnished surface as a background. Patterns of varying depth are cut on the finished background. The result is an unusual and contrasting carving, which gives the product an original appearance.

Embossed carving for furniture, which is usedoften, but to have experience of such work is necessary. In it there is a flat relief carving, that is a kind of an ornament with the selected background. The difference is that the background is made below the ornament, it is specially chosen for this purpose by the chisel. The Kudrin carving with the image of birds, animals, flowers, incredibly beautiful garlands with leaves is unusual. Art was born thanks to the master Vasily Voronov from the village of Kudrino, where the name came from.

Sculptural carving is a separate version, for furniture it is used extremely rarely, since it requires skill.

If you have no experience, it is best to start withsimple options, gradually improving skills. In addition, for complex types of carving, special machines are used that allow processing of three-dimensional parts. Return to contents</a>

Stages of manufacturing carved furniture

A DIY stool is an option for beginners. To work, you need to prepare certain materials and tools: Dependence of the quality of the structure on the design: a – a fragile part due to a large number of connections, b – a strong part made of a solid carved board.

Dependence of the quality of the structure on the design: a – a fragile part due to a large number of connections, b – a strong part made of a solid carved board.

Pine boards. They are the easiest to process, have a beautiful appearance and aroma of needles. You can take not only pine, but also birch planks, alder, lime, for work is suitable oak or karagach.

A set of carpentry tools, including a hammer, chisel, electric jigsaw, saw, drill.

Screwdriver and set of fasteners.

A stain for painting the furniture of the chosen color, instead of it you can use oil, paint. For protection of wood, a clear glossy or matt varnish is used.

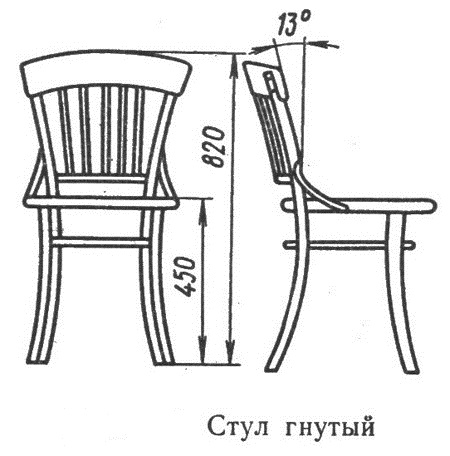

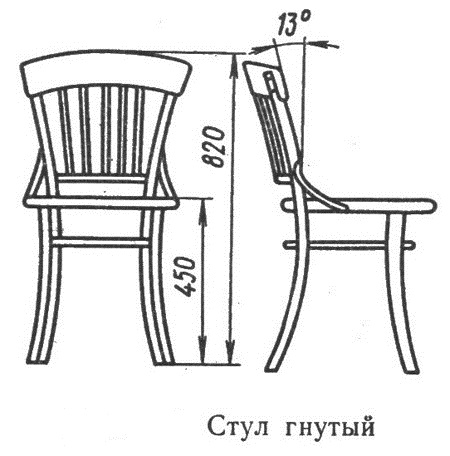

Before making a carved chair, it is necessarymake a drawing, choose a pattern for carving, make a diagram of its execution. If you have no experience, it is better to start with simple patterns. For the back, you can even use plywood sheets, which are easier to cut than a wooden board, and their cost is lower. An example of a diagram for a stool is shown in Fig. 1. Where to start work? The process of carving and making a chair includes the following stages: Bent chair.

Bent chair.

Begin to make carved chairs and stools withprocessing of wood, since this will determine the appearance of the piece of furniture, durability, the absence of cracks on the surface. The wood is taken in autumn or winter blanks, so that the juice movement in it is minimal. These blanks will not crack. If ready boards are used, they should be perfectly dried, do not have large defects, for example, falling knots, pitching of resin, cracks and other. The best materials for home furniture are pine, oak, birch, alder, linden, birch.

For work, you must choose only qualitytools that are designed for carving. Today in stores you can buy ready-made sets, but their cost is quite high, and separately these tools can go much cheaper. Some of them are in many houses. These are chisels, jambs, thicknesser, cricker-grass, corners, malka, scratch, files, kiyanka, coins, saw, electric jigsaw, drill and others. It all depends on what thread is required, what will be the level of complexity.

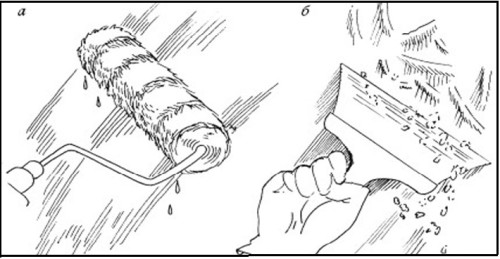

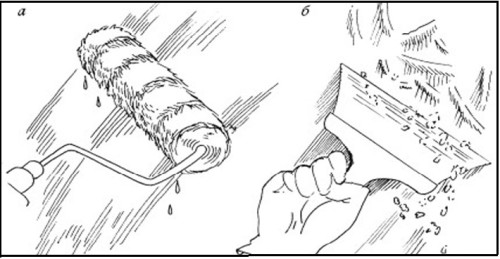

The boards are laid out on a horizontal surface,begin cutting. To do this, it is necessary to mark the surface of the boards in accordance with the drawing. It is desirable to put a designation on each element to make it easier to assemble the finished parts. If there is a circular saw, then the carving is much easier. If it does not, you can use an electric jigsaw. If you use thicker elements for furniture, then they will need to glue PVA.

After all the details are cut and glued,you need to perform a sweep. Beginners make the mistake of applying grinding paper to sandpaper. At the manufacture of wooden furniture at this stage, use only cycling. Then the finished workpiece for threading is fixed on a workbench, with a simple pencil and a stencil (if it is used), a pattern is applied to the surface. Attach the part carefully, as during operation it is necessary to observe the maximum accuracy and accuracy, otherwise hands can easily be damaged.

When markup is applied, you can start cutting. It all depends on which method will be used for the job. For simple options, it is enough to cut holes of different shapes using a jig saw. If a complex three-dimensional thread is used, special machines will be needed. Therefore, experts recommend starting with simple forms.

Return to Contents</a>

How to collect chairs?

are assembled when each part is processed,polished, the surface is smooth and attractive. After that, assembly is performed according to the scheme. Self-tapping screws are required for this, you can use wooden spikes, which are coated with glue. To dry the glue, you need to use a special press or clamps. Methods of expressing tectonics:a - non-tectonic gluing (in growth), b - tectonic gluing of the side edge, c - non-tectonic connection of the side bar with the leg, d, d - tectonic connections of the side bar with the leg. When the furniture is assembled and the glue has dried, it is necessary to carefully clean the chair from dust, for which a regular damp cloth is used. The process is repeated approximately 2-3 times, the chair must dry before starting further finishing. About 3 hours after the wood has dried, you can cover the chair with nitro varnish and polish, leave it for a day to dry. After 24 hours, the surface must be sanded, then re-coated with a layer of polish. After 4 days, a polish mixed with alcohol is used for the coating so that the chair acquires a beautiful mirror shine. Armchairs, tables and other pieces of furniture can be made in a similar way. It is important to immediately select the type of carving and make a drawing for assembly. Carved furniture has always been popular due to its stylish appearance. It is durable and stable, as it is made of natural wood, and its appearance is stylish and elegant, it can perfectly fit into any interior.

Methods of expressing tectonics:a - non-tectonic gluing (in growth), b - tectonic gluing of the side edge, c - non-tectonic connection of the side bar with the leg, d, d - tectonic connections of the side bar with the leg. When the furniture is assembled and the glue has dried, it is necessary to carefully clean the chair from dust, for which a regular damp cloth is used. The process is repeated approximately 2-3 times, the chair must dry before starting further finishing. About 3 hours after the wood has dried, you can cover the chair with nitro varnish and polish, leave it for a day to dry. After 24 hours, the surface must be sanded, then re-coated with a layer of polish. After 4 days, a polish mixed with alcohol is used for the coating so that the chair acquires a beautiful mirror shine. Armchairs, tables and other pieces of furniture can be made in a similar way. It is important to immediately select the type of carving and make a drawing for assembly. Carved furniture has always been popular due to its stylish appearance. It is durable and stable, as it is made of natural wood, and its appearance is stylish and elegant, it can perfectly fit into any interior.

Comments

comments

Compression of chair joints during gluing:a - clamps and a belt tie, 1 - clamp, 2 - belt tie, 3 - a piece of timber or board, b - rope. Tables, chairs, armchairs, cabinets - all this is available for self-made. You only need skill, imagination and patience, since wood carving is a long and painstaking process. If you have no experience in doing such work, then you can start by making a small stool with carved legs. Gradually, you can move on to making tables, armchairs, carved panels for the room. The work must be done based on certain rules and requirements, choosing the type of carving that is most suitable.

Compression of chair joints during gluing:a - clamps and a belt tie, 1 - clamp, 2 - belt tie, 3 - a piece of timber or board, b - rope. Tables, chairs, armchairs, cabinets - all this is available for self-made. You only need skill, imagination and patience, since wood carving is a long and painstaking process. If you have no experience in doing such work, then you can start by making a small stool with carved legs. Gradually, you can move on to making tables, armchairs, carved panels for the room. The work must be done based on certain rules and requirements, choosing the type of carving that is most suitable. Figure 1. Drawing of a stool.

Figure 1. Drawing of a stool. Dependence of the quality of the structure on the design: a – a fragile part due to a large number of connections, b – a strong part made of a solid carved board.

Dependence of the quality of the structure on the design: a – a fragile part due to a large number of connections, b – a strong part made of a solid carved board. Bent chair.

Bent chair. Methods of expressing tectonics:a - non-tectonic gluing (in growth), b - tectonic gluing of the side edge, c - non-tectonic connection of the side bar with the leg, d, d - tectonic connections of the side bar with the leg. When the furniture is assembled and the glue has dried, it is necessary to carefully clean the chair from dust, for which a regular damp cloth is used. The process is repeated approximately 2-3 times, the chair must dry before starting further finishing. About 3 hours after the wood has dried, you can cover the chair with nitro varnish and polish, leave it for a day to dry. After 24 hours, the surface must be sanded, then re-coated with a layer of polish. After 4 days, a polish mixed with alcohol is used for the coating so that the chair acquires a beautiful mirror shine. Armchairs, tables and other pieces of furniture can be made in a similar way. It is important to immediately select the type of carving and make a drawing for assembly. Carved furniture has always been popular due to its stylish appearance. It is durable and stable, as it is made of natural wood, and its appearance is stylish and elegant, it can perfectly fit into any interior.

Methods of expressing tectonics:a - non-tectonic gluing (in growth), b - tectonic gluing of the side edge, c - non-tectonic connection of the side bar with the leg, d, d - tectonic connections of the side bar with the leg. When the furniture is assembled and the glue has dried, it is necessary to carefully clean the chair from dust, for which a regular damp cloth is used. The process is repeated approximately 2-3 times, the chair must dry before starting further finishing. About 3 hours after the wood has dried, you can cover the chair with nitro varnish and polish, leave it for a day to dry. After 24 hours, the surface must be sanded, then re-coated with a layer of polish. After 4 days, a polish mixed with alcohol is used for the coating so that the chair acquires a beautiful mirror shine. Armchairs, tables and other pieces of furniture can be made in a similar way. It is important to immediately select the type of carving and make a drawing for assembly. Carved furniture has always been popular due to its stylish appearance. It is durable and stable, as it is made of natural wood, and its appearance is stylish and elegant, it can perfectly fit into any interior.