When renovation work is being carried out in the house orWhen a new building is being built, the developers always use new, practical and very reliable materials. They are a guarantee of the durability of a new or renovated building. The foam ceiling is easy to clean, itwaterproof, resistant to temperature changes. When it comes to finishing the ceiling surface, builders have the opportunity to choose one of many well-known methods:

The foam ceiling is easy to clean, itwaterproof, resistant to temperature changes. When it comes to finishing the ceiling surface, builders have the opportunity to choose one of many well-known methods:

- stretch ceiling;

- suspended systems;

- plates;

- foam plastic ceilings.

Most often, the ceiling is finished with polystyrene foamtiles that have many positive qualities. It is quite easy to create ceilings from polystyrene foam with your own hands. Such tiles have many positive qualities.

Basic characteristics of tiles

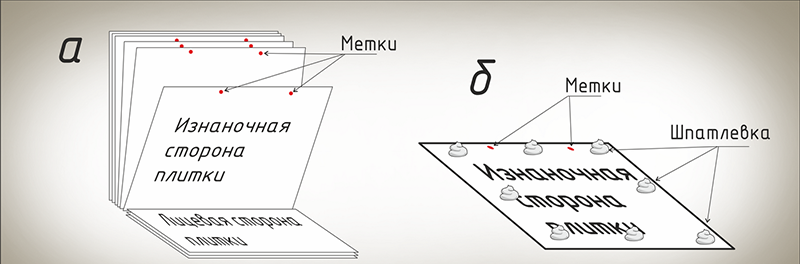

Installation diagram for foam tiles.

Installation diagram for foam tiles.

It is very easy to work with foam tiles,even a very inexperienced builder can install it. Perhaps the most inexpensive ceiling covering, the installation of which does not require the help of professionals, are foam plastic slabs. This material can have a variety of colors, have a laminated or film coating. Such slabs are usually produced in standard sizes:

- 50х50;

- 100x16.5.

For pasting kitchen ceilings it is usedpolystyrene foam, the surface of which is laminated with film. This technology allows you to hide existing irregularities and ceiling defects. Of course, when renovating an apartment, the least expensive option will be to cover the ceiling with polystyrene foam boards. This method is the most popular among builders today. Return to contents</a>

Types of foam plates

Extruded ceiling installation diagrampolystyrene foam. Before you start installation work, you need to study more carefully the existing types of foam plastic boards intended for the ceiling surface. Foam plastic has several varieties:

Extruded ceiling installation diagrampolystyrene foam. Before you start installation work, you need to study more carefully the existing types of foam plastic boards intended for the ceiling surface. Foam plastic has several varieties:

- extruded;

- stamping;

- injection.

Extruded foam is obtained bythe process of polystyrene extrusion. In the original, it is dirty white, so its surface is covered with a film using pressing. Due to the film coating, extruded tiles have a large color palette, they can be easily matched to any interior. This coating is considered the most durable, but it has a normalized thickness. Of course, this becomes a significant drawback, since gaps may appear during installation. Another negative feature is the high cost. Ceiling foam is also manufactured using the stamping method. In this case, a variety of stamps are used, so the tiles are of various shapes. The source material is foam blanks due to their high granularity. Scheme of options for gluing ceiling tiles.The tile is white. These ceiling tiles are painted with water-dispersion paints. If possible, they are laminated. The tile looks very aesthetically pleasing, while having increased operational capacity. Since foam plastic tiles have a very low cost, they have become very popular. However, such tiles also have several negative qualities:

Scheme of options for gluing ceiling tiles.The tile is white. These ceiling tiles are painted with water-dispersion paints. If possible, they are laminated. The tile looks very aesthetically pleasing, while having increased operational capacity. Since foam plastic tiles have a very low cost, they have become very popular. However, such tiles also have several negative qualities:

Before installing ceiling tiles,it is necessary to calculate the required amount of material that will be mounted on the ceiling. First, the area of the room is determined by multiplying the length of the room by its width. The result obtained will help to calculate the required number of tiles, based on the area of the tile itself. The area of the room is divided by the area of the tile itself. The result will show the required number of tiles. However, it should be remembered that some inaccuracies are possible during the work, due to which several tiles may be lost. Therefore, it is necessary to purchase such tiles with a small reserve. If this is not done, then, if necessary, the store may not have the required material. Return to the table of contents</a>

How to glue the ceiling tiles?

To complete the work you will need a variety of tools: Scheme for gluing ceiling tiles.

Scheme for gluing ceiling tiles.

- stationery knife;

- level;

- scissors;

- brushes;

- putty knife;

- stool;

- ladder;

- roulette;

- gon;

- meter;

- twine;

- soft pencil.

Often inexperienced finishers ignore the processmarking and preparatory work. They completely trust their eye, as a result, there are distortions after installation. To get an excellent result, before gluing the tiles, it is imperative to make markings. When installing the first row on a crooked wall, you will get a surface with crooked seams. To avoid such a mistake, it is necessary to draw a perpendicular line from the main wall, from which parallel lines are drawn, at the desired distance. A building level will help to get the perfect marking. To draw an absolutely straight line, you need to use a painter's cord. You need to start gluing foam tiles from the most visible corner of the room. The pasting should end above the door. This way, the last row will not be visible. Basically, it always turns out incomplete. Usually the pattern on such tiles is the same, but during joining it is necessary to maintain symmetry. To get rid of gaps, the tiles must be pressed tightly together. Before gluing, you need to remove burrs from the ends of the ceiling tiles that remain after pressing. Several are known:

Return to Contents</a>

Bonding panels: features

The quality of the foam gluing largely depends onthe reliability of the resulting structure depends. First, a tile blank is made, for which it is cut with a knife to the required dimensions. After this, the foam plastic slabs are installed using glue. During such an operation, certain rules must be followed:

- The supply of electricity must be switched off before starting work;

- work should be carried out in gloves, which will keep the tile clean;

- Adhesive should be applied in small portions around the perimeter;

- Adhesion of the glue before gluing should be equal to three minutes;

- When the tile is glued, it must be strongly pressed against the ceiling;

- The excess glue is removed by damp matter.

For fixing foam tiles to the ceiling,the time of glue hardening, double-sided tape is perfect. After completing the work, the gaps that have arisen at the junction of the walls and the ceiling surface should be hidden. Ceiling polystyrene foam plinth is perfect for this. The room will look much more beautiful with special corner details. A special insert is installed for the chandelier, hiding the wires. All decoration should be done in the same style. The glue should be applied to the inner surface of the tile, over the entire area and diagonally, a kind of cross is obtained. There is no need to cover the ends of the tile with glue, since this increases the thickness of the seams, and glue traces remain on the edges. This work must be done quite quickly, due to the fact that the glue begins to harden in two to three minutes. The tile must be pressed tightly to the ceiling. To achieve uniform adhesion, the resulting surface must be carefully smoothed. To make the seams absolutely invisible, they are first joined and then pressed to the ceiling surface. This technology does not require the use of any special fixation. To make the ceiling look beautiful and to cover the cracks, a foam plinth is glued over the entire area of the room. It is glued in the same way as the tile. To join the corners, the ends of the tile must be cut at 45 degrees. The outer corners are covered with a plastic corner.