In recent years they have become especially populartwo-level plasterboard ceilings. They give the room a special, festive look and serve to mask light sources. They hide all the flaws of the base, for example, cracks that may appear over time on the original ceiling. Is it possible to do it yourself? What do you need to know for this? What materials and tools will you need? Below are recommendations and a description of the technology according to which, if it is accurately followed, it will be possible to make plasterboard yourself. A two-level ceiling will hide even major flaws in the ceiling tiles and give the living room interior a festive look.

A two-level ceiling will hide even major flaws in the ceiling tiles and give the living room interior a festive look.

How to choose the right structure and materials

If a person has not done similar work, thenIt is better to start with a simple option. You can consider various schemes of a two-level ceiling using the relevant literature. But most often it is difficult to make a choice. Therefore, it is better to start with a fairly simple design: it is made with a decrease in the form of a semicircle, which is made along one of the walls. The difference in levels is chosen within 8-12 cm. The device of such a ceiling is within the power of any person who has ever used a tool in his life. The lower level is a semicircle - the mosta common and easy-to-implement version of a two-level ceiling. The next step is to determine the required number of plasterboard sheets. This is relatively easy to do, since they are 2.5 m long and 1200 mm wide. Knowing the area of the room, it is easy to calculate the required amount of material. In order not to make a mistake, it is better to buy 10% more than the figure obtained by calculation. When performing work to lift the sheets, you may need the help of 1-2 people, since the sheets of material are quite heavy. Cutting is done with a construction knife with replaceable blades. Everything you need for the job is purchased at a construction market. To do it yourself, you will need gypsum board sheets with the appropriate reinforcement and fasteners. You will need a simple tool. From this set, an electric drill and a screwdriver are the most expensive and complex items. If a person has the necessary arsenal at home, then the task is simplified. An approximate list of everything you need is attached below. Return to the table of contents</a>

The lower level is a semicircle - the mosta common and easy-to-implement version of a two-level ceiling. The next step is to determine the required number of plasterboard sheets. This is relatively easy to do, since they are 2.5 m long and 1200 mm wide. Knowing the area of the room, it is easy to calculate the required amount of material. In order not to make a mistake, it is better to buy 10% more than the figure obtained by calculation. When performing work to lift the sheets, you may need the help of 1-2 people, since the sheets of material are quite heavy. Cutting is done with a construction knife with replaceable blades. Everything you need for the job is purchased at a construction market. To do it yourself, you will need gypsum board sheets with the appropriate reinforcement and fasteners. You will need a simple tool. From this set, an electric drill and a screwdriver are the most expensive and complex items. If a person has the necessary arsenal at home, then the task is simplified. An approximate list of everything you need is attached below. Return to the table of contents</a>

The ceiling of plasterboard with their own hands: the initial stage

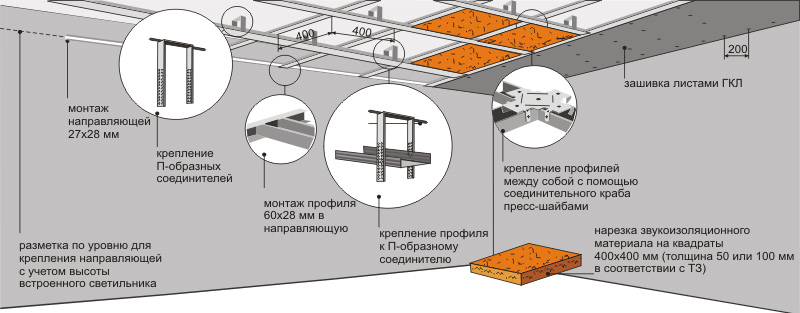

The work begins with marking and assembling the first level frame. This is done using the following technology:

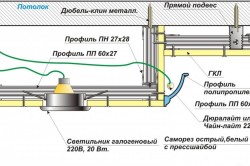

Technology of installation of a plasterboard ceiling. Along the perimeter of the walls, mark a line 8-12 cm from the ceiling with a pencil or a colored marker.

Technology of installation of a plasterboard ceiling. Along the perimeter of the walls, mark a line 8-12 cm from the ceiling with a pencil or a colored marker.This completes the first stage.When carrying out these works, it is necessary to install and secure the electrical wiring on the profiles. For individual light sources, additional fastening elements must be made (this applies to halogen lamps). Holes must be made in the right places. If this is not done, then when covering the ceilings with the main material, it will be impossible to install lighting, therefore, after installing the first tier, it is necessary to secure all electrical fittings and test them in action. Return to the table of contents</a>

Installation of the second level of the ceiling, its putty

The technological process for performing this work is as follows:

Installation scheme for the second level of the ceiling andlighting devices. Begin reinforcing the frame for the second tier, 8-12 cm below the sheets of the first layer along the wall along the perimeter of the entire room, mark the horizontal line with a colored felt-tip pen.

Installation scheme for the second level of the ceiling andlighting devices. Begin reinforcing the frame for the second tier, 8-12 cm below the sheets of the first layer along the wall along the perimeter of the entire room, mark the horizontal line with a colored felt-tip pen.After this, you need to putty the resulting surface.construction, cover the screw heads with special tabs. After applying the putty, wait a few hours for it to dry completely. Put special pads on the screw heads and cover them with putty as well. Then start painting in the colors chosen in advance. First, the entire surface is primed. After that, apply the first coat of paint. After it dries completely, apply the finishing coat. At this point, the work of installing a two-level structure on your own is almost complete. Return to contents</a>

What materials and tools need to be purchased in the construction market?

- sheets of plasterboard (standard);

- profiles of UD and CD;

- Metal and plastic dowels;

- suspension (wire or perforated);

- screws and special plugs for them;

- putty;

- paint;

- electric drill with drills;

- Screwdriver;

- fixtures, electric wires, sockets and switches;

- building level and roulette;

- putty knife;

- brush or paint roller;

- scissors for metal;

- a construction knife with a stock of blades;

- screwdrivers;

- pencil and colored pen.

The production of multi-level structures consists offrom the stages of creating and joining single-tier ceiling systems. With the precise implementation of the above recommendations and operations of the technological process, it is quite possible to create ceilings of the desired configuration. This requires finances and the desire to do something with your own hands.