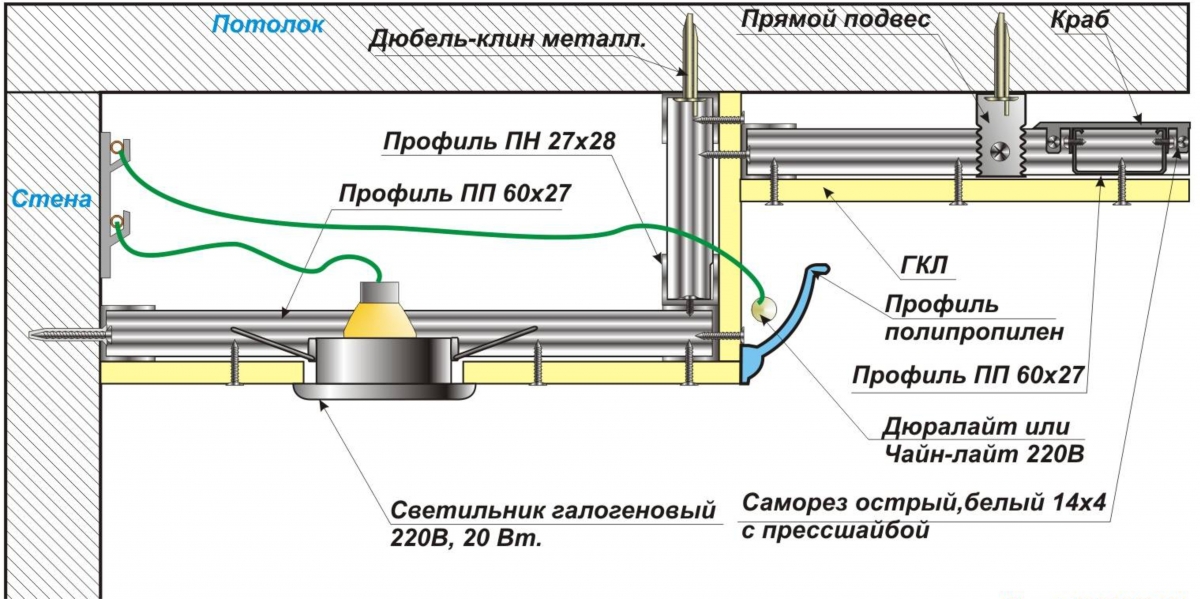

A successful ceiling design can highlightinterior style. If the owner of an apartment or private building has fairly simple construction skills, then the answer to this question is clear: we do it ourselves. Scheme of a two-level suspended ceiling.

Scheme of a two-level suspended ceiling.

Preparatory activities, design

According to the rules for conducting construction or repair workBefore finishing the ceiling, all other construction work related to increasing humidity in the room must be completed. For example, such work as concrete screed, leveling the walls with plaster must be completely hardened. But finishing work begins with the ceiling. At the same time, the humidity in the room should not reach a maximum of 75% at a temperature of 16°. Installation of ceiling mounts.The work on making a plasterboard ceiling begins with checking the degree of curvature of the ceiling using a long bubble level. This must be done without fail and carefully, since the correctness and reliability of the erected frames of the 1st and 2nd levels of the plasterboard ceiling ultimately depends on it. If significant protrusions or cracks are found during the measurements, they must be leveled or filled. The filler must dry, only then can the work be continued. If there are peeling plaster layers on the surface of the ceiling, they must be knocked down to a solid base and re-plastered if a significant defect has formed. All these measures to level and eliminate ceiling deformations are necessary, despite the fact that the installation of a plasterboard structure can hide defects, but it must be securely fastened. After completing these works, it is necessary to make a ceiling project or at least draw a room plan and the design of the future two-level ceiling. The plan that will be drawn must strictly repeat the contours of the ceiling, taking into account all the geometric irregularities of its execution. The purpose of all measurements is to obtain parallel or perpendicular elements that will make up the ceiling. Any distortions must be taken into account when constructing frames and cutting plasterboard sheets.

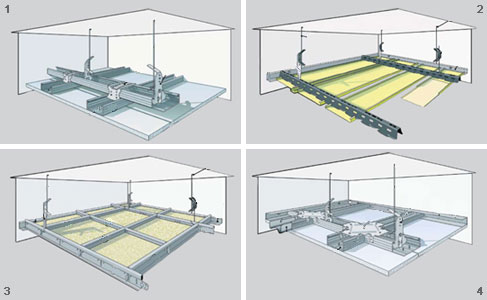

Installation of ceiling mounts.The work on making a plasterboard ceiling begins with checking the degree of curvature of the ceiling using a long bubble level. This must be done without fail and carefully, since the correctness and reliability of the erected frames of the 1st and 2nd levels of the plasterboard ceiling ultimately depends on it. If significant protrusions or cracks are found during the measurements, they must be leveled or filled. The filler must dry, only then can the work be continued. If there are peeling plaster layers on the surface of the ceiling, they must be knocked down to a solid base and re-plastered if a significant defect has formed. All these measures to level and eliminate ceiling deformations are necessary, despite the fact that the installation of a plasterboard structure can hide defects, but it must be securely fastened. After completing these works, it is necessary to make a ceiling project or at least draw a room plan and the design of the future two-level ceiling. The plan that will be drawn must strictly repeat the contours of the ceiling, taking into account all the geometric irregularities of its execution. The purpose of all measurements is to obtain parallel or perpendicular elements that will make up the ceiling. Any distortions must be taken into account when constructing frames and cutting plasterboard sheets. Options for fastening the first level frametwo-level ceiling For ease of further installation work, it is recommended to apply a grid with a 60 cm cell to the ceiling. This is easiest to achieve with a laser level, but if you don’t have one, you can do with a marker construction cord, tape measure, it will just take much more time. Now you can proceed to the final design. At an early stage, there were probably some developments and ideas for the execution of the ceiling. However, it was after building a plan in the actual dimensions of the existing ceiling that adjustments could arise. Most often, a two-level plasterboard ceiling is made in the form of a combination of geometric shapes, for example, one of the levels can be a circle, square, oval. But it is also common to use non-standard shapes, for example, segments of a circle that smoothly flow into an oval or rectangle. The purpose of the ceiling project is to try to hide the geometric asymmetry of the room as much as possible, as well as visually imagine the future ceiling. In addition, there are several rules that must be followed when designing: the 2nd level should not be very narrow (windows and doorways located in the room will only weigh down the interior), and the circle, which should be on the ceiling, must be located strictly in the center. Failure to comply with these rules can lead to a violation of the lighting of the room and distortion of some elements of the interior. The simplest idea of what the ceiling will be like can be obtained by lying on your back and trying on the image of the design drawing to the ceiling, stretching out your arms. Return to the table of contents</a>

Options for fastening the first level frametwo-level ceiling For ease of further installation work, it is recommended to apply a grid with a 60 cm cell to the ceiling. This is easiest to achieve with a laser level, but if you don’t have one, you can do with a marker construction cord, tape measure, it will just take much more time. Now you can proceed to the final design. At an early stage, there were probably some developments and ideas for the execution of the ceiling. However, it was after building a plan in the actual dimensions of the existing ceiling that adjustments could arise. Most often, a two-level plasterboard ceiling is made in the form of a combination of geometric shapes, for example, one of the levels can be a circle, square, oval. But it is also common to use non-standard shapes, for example, segments of a circle that smoothly flow into an oval or rectangle. The purpose of the ceiling project is to try to hide the geometric asymmetry of the room as much as possible, as well as visually imagine the future ceiling. In addition, there are several rules that must be followed when designing: the 2nd level should not be very narrow (windows and doorways located in the room will only weigh down the interior), and the circle, which should be on the ceiling, must be located strictly in the center. Failure to comply with these rules can lead to a violation of the lighting of the room and distortion of some elements of the interior. The simplest idea of what the ceiling will be like can be obtained by lying on your back and trying on the image of the design drawing to the ceiling, stretching out your arms. Return to the table of contents</a>

Materials and Tools

Tools required for work:drill, hammer drill, screwdriver, tape measure, pencil, construction knife, construction level. To make a two-level plasterboard ceiling with lighting, the following materials are required:

Tools required for work:drill, hammer drill, screwdriver, tape measure, pencil, construction knife, construction level. To make a two-level plasterboard ceiling with lighting, the following materials are required:

- profiles of various designs (guides, longitudinal);

- Clamps that connect the elements of the frame;

- Suspensions conventional or spring-loaded for fixing gipsokartonnyh sheets to the ceiling;

- self-tapping screws;

- Dowels for fixing profiles to walls;

- scissors for work on metal;

- drill or perforator (usually two in one);

- electric or battery screwdriver;

- a construction knife with spare blades;

- tape measure and pencil;

- building level.

When assembling the frame, nails must not be used.fastening to the ceiling. The reliability of the structure can be ensured by dowels or anchor bolts, since the plasterboard structure has a significant weight. Return to the table of contents</a>

Installation of a two-level ceiling made of plasterboard

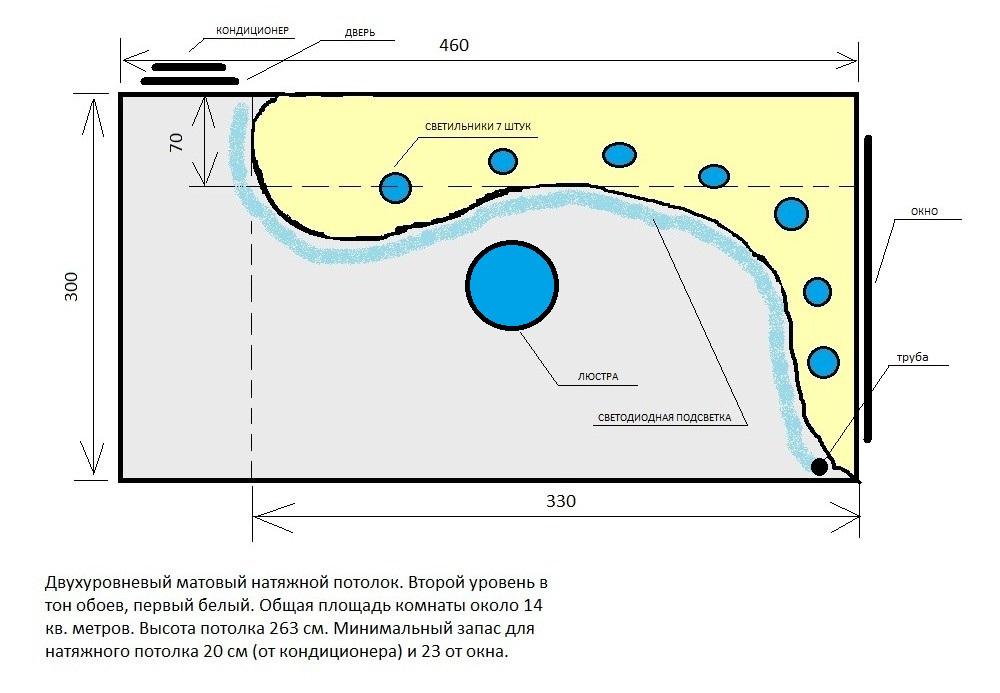

Scheme of a two-level matte stretch ceiling. Before starting work on installing the frame, it is necessary to choose the method of its fastening and the assembly sequence:

Scheme of a two-level matte stretch ceiling. Before starting work on installing the frame, it is necessary to choose the method of its fastening and the assembly sequence:

The assembly of the frame begins with marking and beatinglevel. The corner with the minimum distance between the ceiling and the floor will serve as the basic starting point for the marking. Next, using a colored construction cord, draw a horizontal level line for attaching the profile to the wall. Using a laser level for this type of work would be optimal. After that, a guide profile is attached to the wall along the perimeter and to the ceiling with dowels or anchor bolts. The distance between the dowels does not exceed 60 cm. If rounded elements or a circle are provided on the ceiling, these bends are formed using metal scissors, which make cuts on the profile and bend it. Next, hangers are attached to the ceiling at intervals of 60 cm and more often if the ceiling configuration is not straight. Next, longitudinal profiles are attached to the hangers with self-tapping screws for metal. To give rigidity to the frame, crossbars are attached between the long spans of the longitudinal profiles. The resulting frame of the first tier is sheathed with plasterboard. Fastening is carried out with self-tapping screws using a screwdriver. If it is necessary to cut a sheet of drywall, this is done with a knife, which is used to cut the sheet and then break it. It should be said that the electrical wires that are necessary for connecting built-in lamps, if provided for by the project, or general lighting devices, are laid in special sleeves at the stage of installing the frame. The holes in which the built-in lamps will be mounted are cut before attaching the sheets to the frame according to the preliminary marking. However, the backlight can be done using an LED strip, which is glued directly to the drywall sheets and allows for soft lighting, holes are not needed. The frame of the second tier is mounted similarly to the first level. But for it, the starting point is the 1st level. Pieces of longitudinal profile serve as hangers for the 2nd tier. The joints between the sheets, seams with the wall and screw heads must be putty and sanded with sandpaper or a grinder. The installation is complete.