It is possible to tile and level any type of wallsusing plasterboard sheets. They are able to cope with this task perfectly. The material has good strength, light weight. The method of installing plasterboard is quite flexible, due to which the material can be used as efficiently as possible. Wall cladding with plasterboard allows you to hide the unevenness of the walls or install a partition if necessary. This process can be done with your own hands. You will only need to choose a suitable method for fixing the sheets and decide on the shape of the final result. Construction of a wooden frame for plasterboard. There are only two technologies for mounting sheets on a wall:

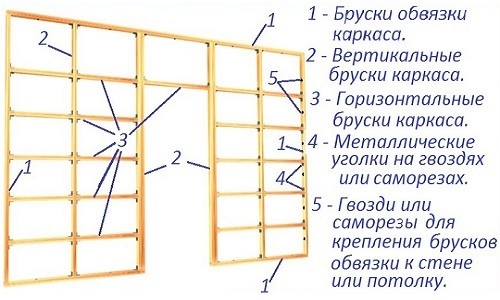

Construction of a wooden frame for plasterboard. There are only two technologies for mounting sheets on a wall:

Types of metal profiles for plasterboard.In some cases, both methods are combined to properly join walls, plastered and drywall. The most reliable and simple method is the frame method. To form a frame, you will need to use a metal profile, to which screws and sheets will be screwed in the future. The disadvantage of this method of fastening is the large thickness of the sheathing (more than 4 cm). As a result, the useful area of the room will decrease by several m². Elements that will be needed to complete the cladding of the walls with drywall:

Types of metal profiles for plasterboard.In some cases, both methods are combined to properly join walls, plastered and drywall. The most reliable and simple method is the frame method. To form a frame, you will need to use a metal profile, to which screws and sheets will be screwed in the future. The disadvantage of this method of fastening is the large thickness of the sheathing (more than 4 cm). As a result, the useful area of the room will decrease by several m². Elements that will be needed to complete the cladding of the walls with drywall: Tool for working with plasterboard.

Tool for working with plasterboard.

- sheets of plasterboard;

- self-tapping screws;

- metal profiles;

- priming composition;

- antiseptic means;

- a marker or a simple pencil;

- building level;

- knife for construction;

- self-adhesive tape;

- putty;

- bars;

- an adhesive solution;

- water;

- sandpaper;

- dowels;

- screws.

Necessary preliminary work before facing the walls

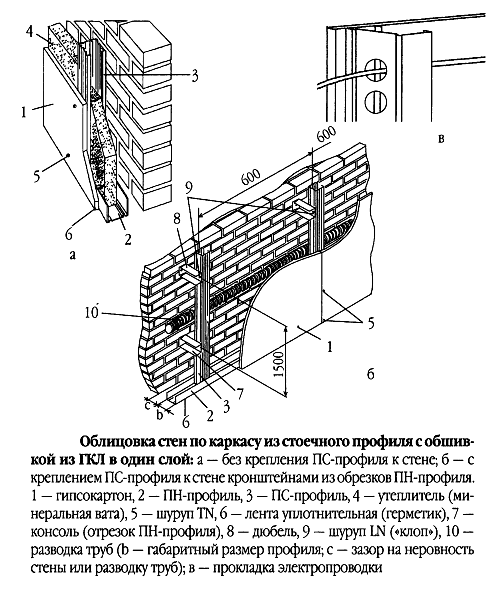

Scheme of fastening gypsum board to metalframe. In this case, you cannot do without preparatory work. Before performing the cladding of the walls in an apartment or a private house, you will need to remove all the old coating from the surface. This is especially true for the plaster mixture and shingles, which easily peel off from the wall. Removing the old coating will allow you to get rid of the extra cm that are occupied by the cladding layer. It is advisable to prime the wall. The surface must be treated with antiseptic compounds, especially if you plan to sheathe the outer wall. On the floor near the wall and ceiling, you will need to draw the lines of the boundaries of the wall, which will be faced with plasterboard sheets. Return to the table of contents</a>

Scheme of fastening gypsum board to metalframe. In this case, you cannot do without preparatory work. Before performing the cladding of the walls in an apartment or a private house, you will need to remove all the old coating from the surface. This is especially true for the plaster mixture and shingles, which easily peel off from the wall. Removing the old coating will allow you to get rid of the extra cm that are occupied by the cladding layer. It is advisable to prime the wall. The surface must be treated with antiseptic compounds, especially if you plan to sheathe the outer wall. On the floor near the wall and ceiling, you will need to draw the lines of the boundaries of the wall, which will be faced with plasterboard sheets. Return to the table of contents</a>

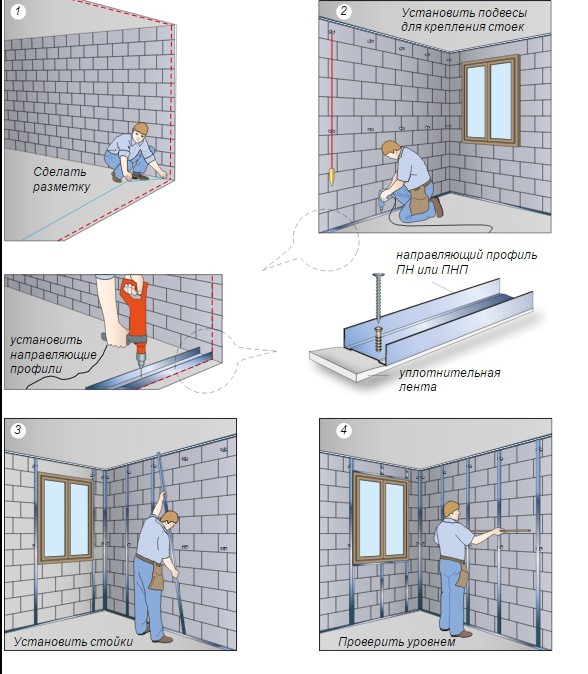

How to build a skeleton correctly: instruction

At this stage, the technology of wall cladding with plasterboard involves the construction of a frame structure. The following steps will need to be performed: Scheme of fastening plasterboard with glue.

Scheme of fastening plasterboard with glue.

Return to Contents</a>

How to fix gipsokartonnye sheets correctly?

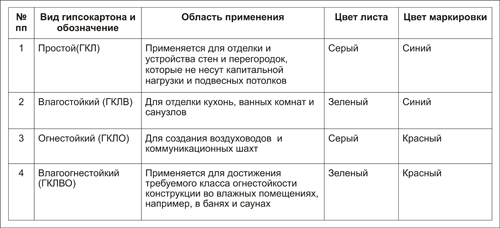

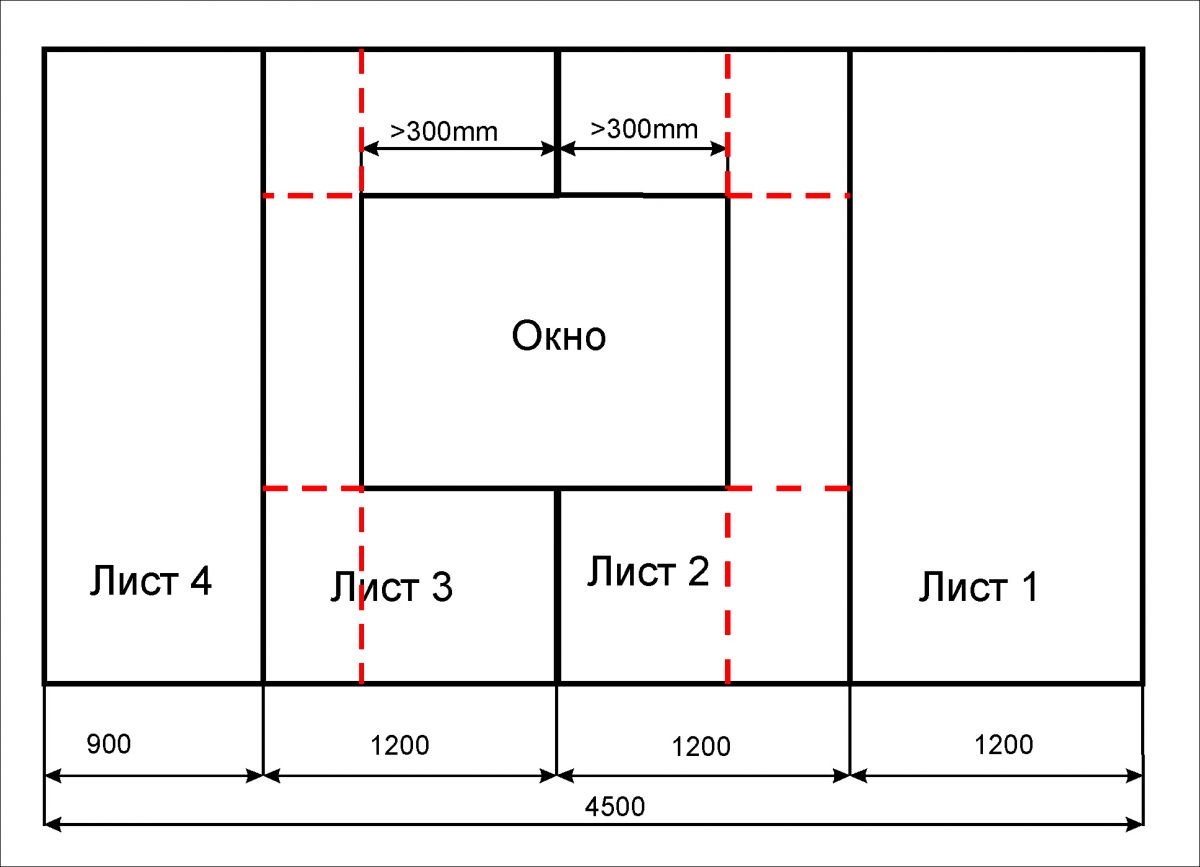

Types of plasterboard, area of application and theircolor marking. It will be possible to mount plasterboard sheets on the prepared frame structure. For this, 35 mm black iron screws are used. It is most convenient to screw them in using a screwdriver. In this way, it will be possible to completely deepen the heads of the fasteners into the sheet. Screws should be mounted every 10-15 cm along the perimeter and in the central part of the sheet. In most cases, sheets are supplied with a central line on the front side, due to which the process will be facilitated. In order to fill the gaps that do not fit whole sheets, you will need to cut out pieces of the required sizes. For cutting, you can use an ordinary construction knife. The paper of the sheet must be cut along the line, then break the sheet. At the end, the paper must be cut on the back side. At this stage, the cladding is complete, all that remains is to complete the finishing. Return to the table of contents</a>

Types of plasterboard, area of application and theircolor marking. It will be possible to mount plasterboard sheets on the prepared frame structure. For this, 35 mm black iron screws are used. It is most convenient to screw them in using a screwdriver. In this way, it will be possible to completely deepen the heads of the fasteners into the sheet. Screws should be mounted every 10-15 cm along the perimeter and in the central part of the sheet. In most cases, sheets are supplied with a central line on the front side, due to which the process will be facilitated. In order to fill the gaps that do not fit whole sheets, you will need to cut out pieces of the required sizes. For cutting, you can use an ordinary construction knife. The paper of the sheet must be cut along the line, then break the sheet. At the end, the paper must be cut on the back side. At this stage, the cladding is complete, all that remains is to complete the finishing. Return to the table of contents</a>

Final finishing of walls and partitions

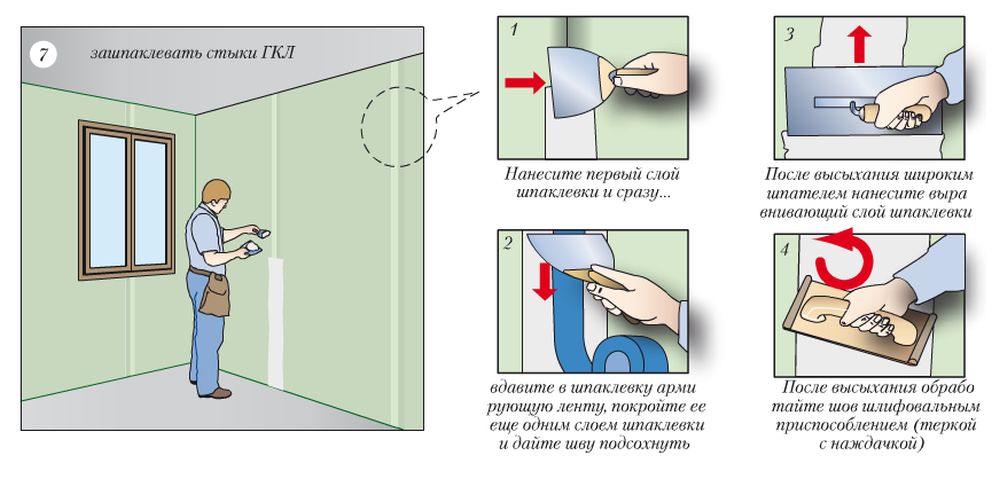

Stages of installing a frame for plasterboard onwall. On the edge of each sheet there is a small strip below the material level. This line simplifies the sealing of the seams. To perform this procedure, you need to use a special self-adhesive mesh. A layer of starting putty mixture is applied on top of it to align the depression with the main level. In the future, the process of processing the sheets will depend on the cladding used. If you plan to lay tiles or any dense material, then you will only need to cover the joints with putty. For painting and wallpapering, you will need to open the entire base of the plasterboard wall with a finishing putty mixture. The putty layer should be approximately 1-2 mm, no more. Next, the base will need to be sanded and primed. Before painting, the base should be brought to perfection, so the sanding process can alternate with the application of additional layers of putty mixture. Paper tape can give the greatest strength to the seams. It has good tensile strength and is not subject to stretching. The stronger the tape and the thinner the thickness, the better the material. When choosing a paper tape, it is recommended to give preference to less smooth devices: a rough base will provide excellent adhesion to the putty mixture and will not peel off. The quality of the tape installation is also affected by the presence of small holes on its surface, which will facilitate the release of air from under the reinforcing product, and also prevent the appearance of bubbles. Return to contents</a>

Stages of installing a frame for plasterboard onwall. On the edge of each sheet there is a small strip below the material level. This line simplifies the sealing of the seams. To perform this procedure, you need to use a special self-adhesive mesh. A layer of starting putty mixture is applied on top of it to align the depression with the main level. In the future, the process of processing the sheets will depend on the cladding used. If you plan to lay tiles or any dense material, then you will only need to cover the joints with putty. For painting and wallpapering, you will need to open the entire base of the plasterboard wall with a finishing putty mixture. The putty layer should be approximately 1-2 mm, no more. Next, the base will need to be sanded and primed. Before painting, the base should be brought to perfection, so the sanding process can alternate with the application of additional layers of putty mixture. Paper tape can give the greatest strength to the seams. It has good tensile strength and is not subject to stretching. The stronger the tape and the thinner the thickness, the better the material. When choosing a paper tape, it is recommended to give preference to less smooth devices: a rough base will provide excellent adhesion to the putty mixture and will not peel off. The quality of the tape installation is also affected by the presence of small holes on its surface, which will facilitate the release of air from under the reinforcing product, and also prevent the appearance of bubbles. Return to contents</a>

Wall cladding with plasterboard: GKL bonding method

Wall marking scheme for plasterboard.If you do not want to lose space and build a frame structure, you can use another method of facing the walls with plasterboard. To glue the sheets, you will need to level the main irregularities on the wall in the form of bumps and holes. After that, the wall cladding itself can be done. The wall must first be primed. The sheets must be cut for laying along the entire wall. It is necessary to take into account that you will need to leave gaps under the ceiling structure and above the floor base of approximately 5 cm so that the adhesive mixture on which the plasterboard sheets will be held dries better. You will need to drill holes for the dowels along the entire wall. The fasteners are screwed into them so that the caps are in the same plane. This is necessary in order to correctly position the sheets. Otherwise, it will not be possible to align the bases of the sheets and adjust them to the wall.

Wall marking scheme for plasterboard.If you do not want to lose space and build a frame structure, you can use another method of facing the walls with plasterboard. To glue the sheets, you will need to level the main irregularities on the wall in the form of bumps and holes. After that, the wall cladding itself can be done. The wall must first be primed. The sheets must be cut for laying along the entire wall. It is necessary to take into account that you will need to leave gaps under the ceiling structure and above the floor base of approximately 5 cm so that the adhesive mixture on which the plasterboard sheets will be held dries better. You will need to drill holes for the dowels along the entire wall. The fasteners are screwed into them so that the caps are in the same plane. This is necessary in order to correctly position the sheets. Otherwise, it will not be possible to align the bases of the sheets and adjust them to the wall. Scheme of puttying seams of plasterboard panels.The adhesive mixture should be prepared using special dry compounds, adding water in the required amount during mixing. The result should be a mixture that is similar in consistency to a paste. It dries quickly, so it is recommended to dilute it immediately before fixing the gypsum board. The base of the sheet is thoroughly cleaned of dust to ensure better adhesion with the adhesive solution. Such a mixture is applied to the back of the sheet in piles and longitudinal stripes along the edges of the gypsum board and in its central part. The piles should be placed at a distance of 25-30 cm from each other. It is not allowed to level them into a single layer, since more solution will be consumed, as a result of which the sheet will not be able to properly join over the entire area to the wall. Next, the sheet must be attached to the wall and pressed evenly against the caps of the fasteners. If necessary, you can use a rubber hammer. To prevent holes from being punched, it is recommended to attach wooden boards or bars to the sheet and then tap them with a hammer. Once the finishing of the walls with plasterboard sheets is completed, you will need to wait until the adhesive solution dries completely. The drying time can be found out after reading the instructions on the package. All further work can be done only after the glue has dried. The seams between the sheets will need to be sealed with a mesh, and then covered with a starting putty to the general level of the sheets. The finishing putty for the entire base is used only if necessary. Regardless of which method of facing the walls with plasterboard is chosen, as a result you can get a perfectly flat and smooth base, and there is no need to plaster the surface. The method with gluing sheets is suitable if there is a need to perform partial repair work on the walls, form a partition or arch. If the perforated plasterboard is slightly wet, it can take any shape. Facing the walls with plasterboard sheets is a simple process. You only need to take into account all the existing nuances, as well as follow the correct sequence of actions for cladding.

Scheme of puttying seams of plasterboard panels.The adhesive mixture should be prepared using special dry compounds, adding water in the required amount during mixing. The result should be a mixture that is similar in consistency to a paste. It dries quickly, so it is recommended to dilute it immediately before fixing the gypsum board. The base of the sheet is thoroughly cleaned of dust to ensure better adhesion with the adhesive solution. Such a mixture is applied to the back of the sheet in piles and longitudinal stripes along the edges of the gypsum board and in its central part. The piles should be placed at a distance of 25-30 cm from each other. It is not allowed to level them into a single layer, since more solution will be consumed, as a result of which the sheet will not be able to properly join over the entire area to the wall. Next, the sheet must be attached to the wall and pressed evenly against the caps of the fasteners. If necessary, you can use a rubber hammer. To prevent holes from being punched, it is recommended to attach wooden boards or bars to the sheet and then tap them with a hammer. Once the finishing of the walls with plasterboard sheets is completed, you will need to wait until the adhesive solution dries completely. The drying time can be found out after reading the instructions on the package. All further work can be done only after the glue has dried. The seams between the sheets will need to be sealed with a mesh, and then covered with a starting putty to the general level of the sheets. The finishing putty for the entire base is used only if necessary. Regardless of which method of facing the walls with plasterboard is chosen, as a result you can get a perfectly flat and smooth base, and there is no need to plaster the surface. The method with gluing sheets is suitable if there is a need to perform partial repair work on the walls, form a partition or arch. If the perforated plasterboard is slightly wet, it can take any shape. Facing the walls with plasterboard sheets is a simple process. You only need to take into account all the existing nuances, as well as follow the correct sequence of actions for cladding.