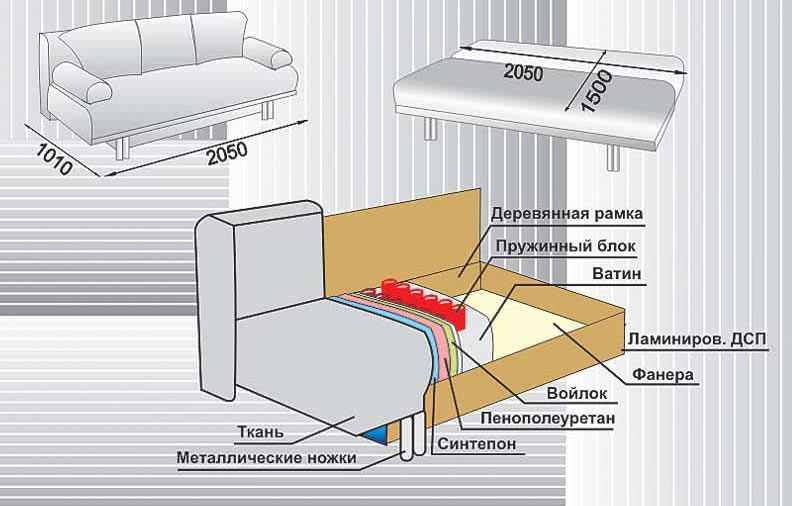

A sofa book is easy to make with your own hands. To do this, you will need to make a drawing. When assembled, the parameters of such furniture should be 1x2.2 m, and when unfolded - 1.4x2.2 m. Scheme of the sofa arrangement.

Scheme of the sofa arrangement.

Preparatory work

To make a sofa bed, you will needfoam rubber, fabric, transformation mechanism, slats, 1.7x2.75 mm fiberboard, furniture bolts (8x120, 6x40 and 6x70), nuts, 100 mm nails, self-tapping screws (89D and 51D), staples (10 and 16 mm), 40x60 mm timber and 1900x200 board. The following tools are required:

- saw;

- Screwdriver;

- pencil;

- a hammer;

- gon.

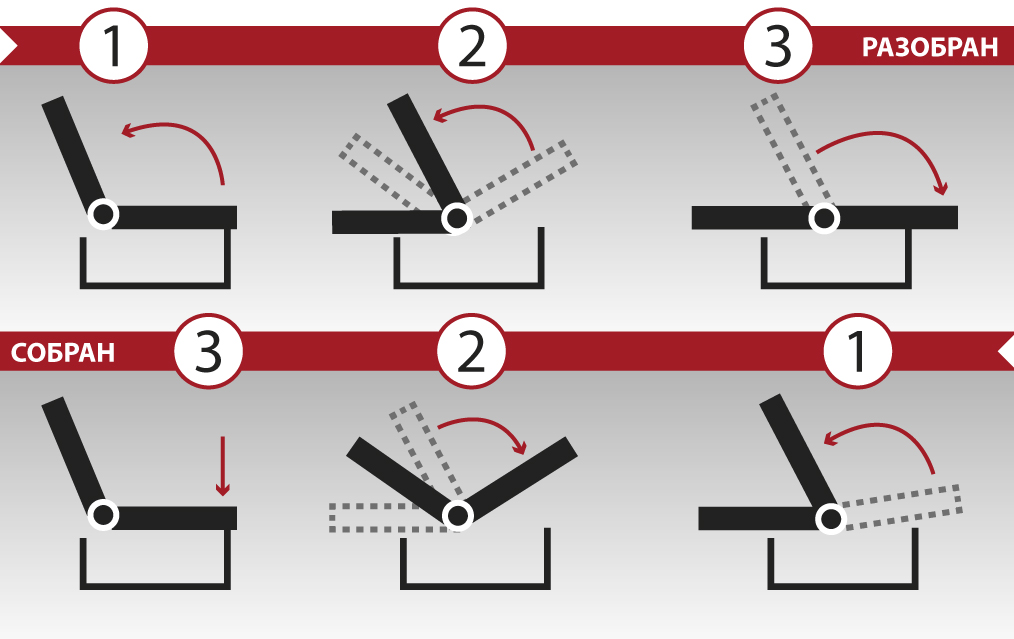

Scheme of disassembly and assembly of a sofa book. The sofa box is made of the following materials (mm):

Scheme of disassembly and assembly of a sofa book. The sofa box is made of the following materials (mm):

- 2 boards 1900х200;

- 2 boards 800x200;

- 2 boards 50x200;

- 4 beams 50х50.

To strengthen the niche structure, you will need 2crossbars (1800x800 mm). The next stage involves assembling the drawer. The furniture frame is made from a 40x60 mm bar, screws and nails. Pre-drill holes for the fasteners. Use a drill and a 3 mm drill bit for this. If the nails are hammered in, screw 89D screws (8 mm drill bit) into the joints. The depth of each hole should be 10 mm. Wooden slats are nailed to the resulting frames (to support the mattress). The armrests are made from 25 mm thick, 1 m long chipboard. Pre-drill 2 left and 2 right walls from the material taking into account the dimensions indicated in the drawing. The length of the wooden frame for the backrests should be 20 mm shorter than the material itself. Holes are made in the frame using an 8.5 mm drill. Bolts of 8x120 mm are inserted into them. The next stage involves assembling all parts of the sofa. The transformation mechanisms are installed so that a gap of 10 mm is formed between the back and the seat, while the furniture should be in the unfolded state. If necessary, the backs and seat are reinforced with wooden slats. Foam rubber is used for upholstery of the sofa-book. First, non-woven fabric is laid on the slats. Pieces with parameters of 50x95 mm are cut out of the insulation. Foam rubber 200 mm wide is placed on the edge of the seat. The back of the product is done in a similar way. A second layer of foam rubber 40 mm thick is placed on top. Covers are pulled over the furniture. A bolster is made on the armrests. Initially, the width of the foam rubber should be 150 mm, and then 50 mm. A second layer of this material (20 mm thick) is placed on top and folded onto the foam rubber bolster. The excess is removed. The part is unfolded with bolts towards itself. The material is glued at a level of 320 mm from the lower edge of the product. The armrests are covered with fabric. The fittings are nailed on the front side. The sofa is assembled. Return to the table of contents</a>

Eurobook yourself

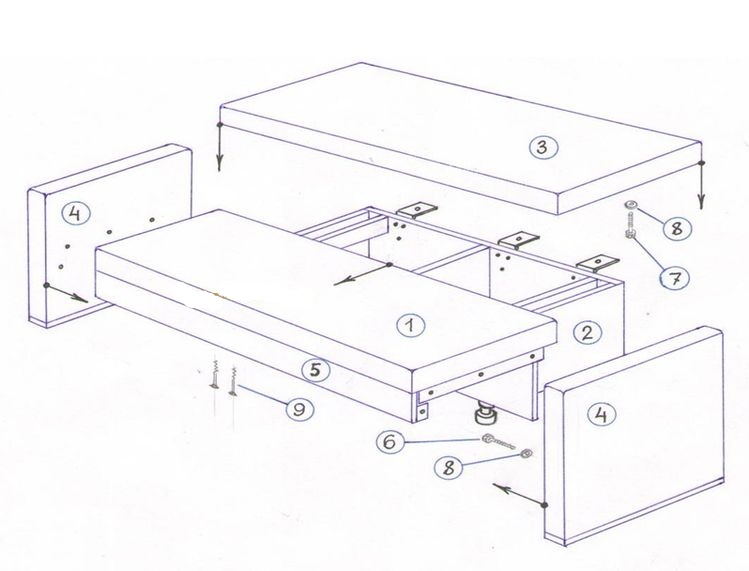

Sofa assembly diagram:1 – seat, 2 – drawer, 3 – back, 4 – sides, 5 – front bar, 6 – bolts 6*40, 7 – bolts 6 * 30, 8 – washers, 9 – self-tapping screws. Eurobook is a modern piece of furniture consisting of the following parts:

Sofa assembly diagram:1 – seat, 2 – drawer, 3 – back, 4 – sides, 5 – front bar, 6 – bolts 6*40, 7 – bolts 6 * 30, 8 – washers, 9 – self-tapping screws. Eurobook is a modern piece of furniture consisting of the following parts:

- backrests;

- seats;

- basis;

- sidewalls.

If desired, a niche can be arranged in the base forlinen. The transformation mechanism of such a sofa involves moving the seat forward (using guides) and folding the back into a horizontal position. To make a Eurobook with your own hands, you will need:

- foam rubber;

- lightning length of 20 cm;

- 3 zippers for 7 cm for pillows;

- material;

- metal grid;

- corner;

- beams 21x7 cm;

- self-tapping screws 89D.

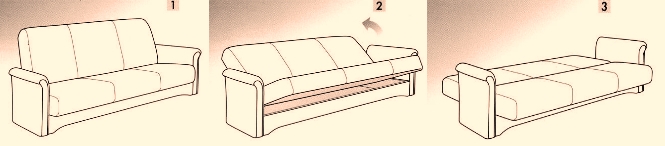

Sofa layout diagram with mechanismtransformation Book. Initially, a drawing of the future sofa is prepared. The sofa frame is made of beams taking into account the parameters of the sofa components (see the drawing for the dimensions of the parts). This will require a saw and a tape measure. Furniture legs are made of a similar material. 8x120 mm bolts are used to attach the beams. The next step is to make the back. This will require 25 mm thick chipboard. The resulting structure is attached to the base of the sofa using thick metal corners. The angle of the back is selected taking into account individual preferences. The support grid is made of armor mesh. The design is designed to hold the seat cushions. The mesh is attached to the wooden base with metal staples. To increase reliability, transverse elements are glued to the longitudinal frame supports. The soft upholstery of the Eurobook is created in a certain sequence. Several pieces of foam rubber are cut out (the dimensions must match the parameters of the backrest) more than 15 cm thick. The parts are covered with material. Zippers are used to connect them. The mattress can be attached to the base of the furniture using decorative tape. The last element is made of material and Velcro. One end of the tape is attached to the frame using small nails, and the other - to the sofa cover. For a Eurobook, you will need to make 3 covers. They are stuffed with foam rubber. This method can be used to make pillows. Return to contents</a>

Sofa layout diagram with mechanismtransformation Book. Initially, a drawing of the future sofa is prepared. The sofa frame is made of beams taking into account the parameters of the sofa components (see the drawing for the dimensions of the parts). This will require a saw and a tape measure. Furniture legs are made of a similar material. 8x120 mm bolts are used to attach the beams. The next step is to make the back. This will require 25 mm thick chipboard. The resulting structure is attached to the base of the sofa using thick metal corners. The angle of the back is selected taking into account individual preferences. The support grid is made of armor mesh. The design is designed to hold the seat cushions. The mesh is attached to the wooden base with metal staples. To increase reliability, transverse elements are glued to the longitudinal frame supports. The soft upholstery of the Eurobook is created in a certain sequence. Several pieces of foam rubber are cut out (the dimensions must match the parameters of the backrest) more than 15 cm thick. The parts are covered with material. Zippers are used to connect them. The mattress can be attached to the base of the furniture using decorative tape. The last element is made of material and Velcro. One end of the tape is attached to the frame using small nails, and the other - to the sofa cover. For a Eurobook, you will need to make 3 covers. They are stuffed with foam rubber. This method can be used to make pillows. Return to contents</a>

Panel construction

If you have no experience working with wood, craftsmen recommend using improvised materials when making a sofa bed:

- metal staples;

- 2 door leaves;

- foam rubber;

- material for upholstery.

For making the base and backsofa-books use 2 old door leaves. They are pre-cleaned from dirt and the old coating. The surface is sanded and painted in the desired color. If desired, the coating is finished with veneer. The door is attached with nails to the hemp. The 2nd part is fixed to it with glue and metal staples. The mattress for such a sofa is made by hand. To do this, you will need to cut out foam rubber of the appropriate size. It is covered with fabric on top. High-quality fabric is pulled over the material. A mattress with pillows is placed on the base of the structure. The transformation mechanism is installed in the same way as in the first case. When making a sofa-book yourself, special attention is paid to the reliability and durability of the frame base. This is due to the fact that this part of the furniture bears the main load. The material for making furniture is selected taking into account the number of people in the family. The finished sofa is decorated at your discretion.