Wooden parquet is a reliable and durable floor covering. Do-it-yourself parquet sanding will come to the rescue if the surface has lost its attractiveness. Installation of a wooden floor on floor beams.And this can happen even with careful maintenance, not to mention those areas of the flooring where people walk in street shoes and move furniture.

Installation of a wooden floor on floor beams.And this can happen even with careful maintenance, not to mention those areas of the flooring where people walk in street shoes and move furniture.

When it is not necessary to polish the parquet?

Sanding a wooden floor.Please note: in some cases, floor covering elements are so damaged that sanding them is pointless. This will not return the floor to normal condition. Such serious damage includes the following cases:

Sanding a wooden floor.Please note: in some cases, floor covering elements are so damaged that sanding them is pointless. This will not return the floor to normal condition. Such serious damage includes the following cases:

Return to Contents</a>

What will it take to work?

There are 2 methods of grinding:machine and manual. The first case will require more material resources, and the second - time and effort. Manual grinding is done using a hand scraper. In addition, you can attach sandpaper to the sole of your shoes and sand the surface with your feet. These methods are quite labor-intensive. Installation of parquet flooring.To simplify the surface leveling, you will need a grinding machine. There are several types of such equipment, each of which is designed for a specific stage of work:

Installation of parquet flooring.To simplify the surface leveling, you will need a grinding machine. There are several types of such equipment, each of which is designed for a specific stage of work:

In addition to the grinder, you will need an industrial vacuum cleaner to remove dust and scissors for the sandpaper. The following materials are needed:

- putty;

- sandpaper;

- oil or varnish;

- brushes and rollers;

- trowel rubber.

Return to Contents</a>

Step-by-step execution of work

Do-it-yourself parquet sanding.The room should be cleared of furniture, the baseboards removed and checked for torn off elements. If torn off planks are found, they should be glued back in place. At this stage, the necessary repair work on the parquet is carried out. If the heads of screws or nails rise above the surface, they should be sunk by 2-3 mm. Next, the floor is washed and vacuumed. This completes the preparation, and they move on to the main work. Coarse sandpaper is loaded onto the drum of the sander. Depending on the nature of the parquet finish, its size is selected:

Do-it-yourself parquet sanding.The room should be cleared of furniture, the baseboards removed and checked for torn off elements. If torn off planks are found, they should be glued back in place. At this stage, the necessary repair work on the parquet is carried out. If the heads of screws or nails rise above the surface, they should be sunk by 2-3 mm. Next, the floor is washed and vacuumed. This completes the preparation, and they move on to the main work. Coarse sandpaper is loaded onto the drum of the sander. Depending on the nature of the parquet finish, its size is selected:

- for removing varnish or drying oil - No. 16;

- for removing the top layer of wood and paint - No. 24-40;

- universal option for any work - No. 60.

First, the machine goes diagonally across the room.from one corner to the other. After that, move to one of the walls and move the machine along the wall, and then parallel to it. With each subsequent pass, you need to shift by 10 cm. It is very important to observe the correct direction of movement. Sanding should be performed along the wood fibers. Only when turning is a short-term crosswise pass allowed. For artistic parquet with a spiral pattern, you also need to move spirally from the edge to the center. To avoid the formation of depressions on the surface, it is necessary to lift and lower the machine while moving. At the first stage of work, hard-to-reach places are skipped. It is necessary to adjust the drum pressure on the floor. For this purpose, the machine is equipped with a special screw. To remove varnish stains in hard-to-reach places and in the center, use a "boot". If a poorly processed piece is located in the center, then the machine is moved from the edge of the stain to its middle in a circular motion. Near the edges and in the corners, movements are made from the edge to the wall and back to remove the top layer of the surface. Technical characteristics of parquet.Next, fine grinding is performed with a flat grinding machine. As a result of this treatment, the surface should not have even the slightest defects: scratches, burrs, etc. The treatment is performed once with sandpaper No. 40, 60, 80 and 100. 1 time means forward and reverse passes. Then the parquet is puttied. The floor is thoroughly vacuumed to clean the cracks from dust. It is best to use a special composition for puttying that imitates wood in color. Puttying is performed over the entire surface using a special rubber spatula. The composition should be distributed evenly to fill all the cracks between individual elements of the parquet and on their surface. When the putty begins to dry and is not sticky, but has not yet begun to harden, it is necessary to imitate the joints. This work must be done very quickly. A metal ruler and an awl are used for this. If you hold the ruler with pressure, you can make curved joints. Excess putty is removed during final sanding. This is done only after the composition has completely dried. Sanding of the parquet is performed with a flat sanding machine with sandpaper No. 100. The pressure of the drum should be reduced, the direction of movement should be along the wood grain. Sanding is performed until the surface becomes perfectly smooth. Return to the table of contents</a>

Technical characteristics of parquet.Next, fine grinding is performed with a flat grinding machine. As a result of this treatment, the surface should not have even the slightest defects: scratches, burrs, etc. The treatment is performed once with sandpaper No. 40, 60, 80 and 100. 1 time means forward and reverse passes. Then the parquet is puttied. The floor is thoroughly vacuumed to clean the cracks from dust. It is best to use a special composition for puttying that imitates wood in color. Puttying is performed over the entire surface using a special rubber spatula. The composition should be distributed evenly to fill all the cracks between individual elements of the parquet and on their surface. When the putty begins to dry and is not sticky, but has not yet begun to harden, it is necessary to imitate the joints. This work must be done very quickly. A metal ruler and an awl are used for this. If you hold the ruler with pressure, you can make curved joints. Excess putty is removed during final sanding. This is done only after the composition has completely dried. Sanding of the parquet is performed with a flat sanding machine with sandpaper No. 100. The pressure of the drum should be reduced, the direction of movement should be along the wood grain. Sanding is performed until the surface becomes perfectly smooth. Return to the table of contents</a>

Finishing

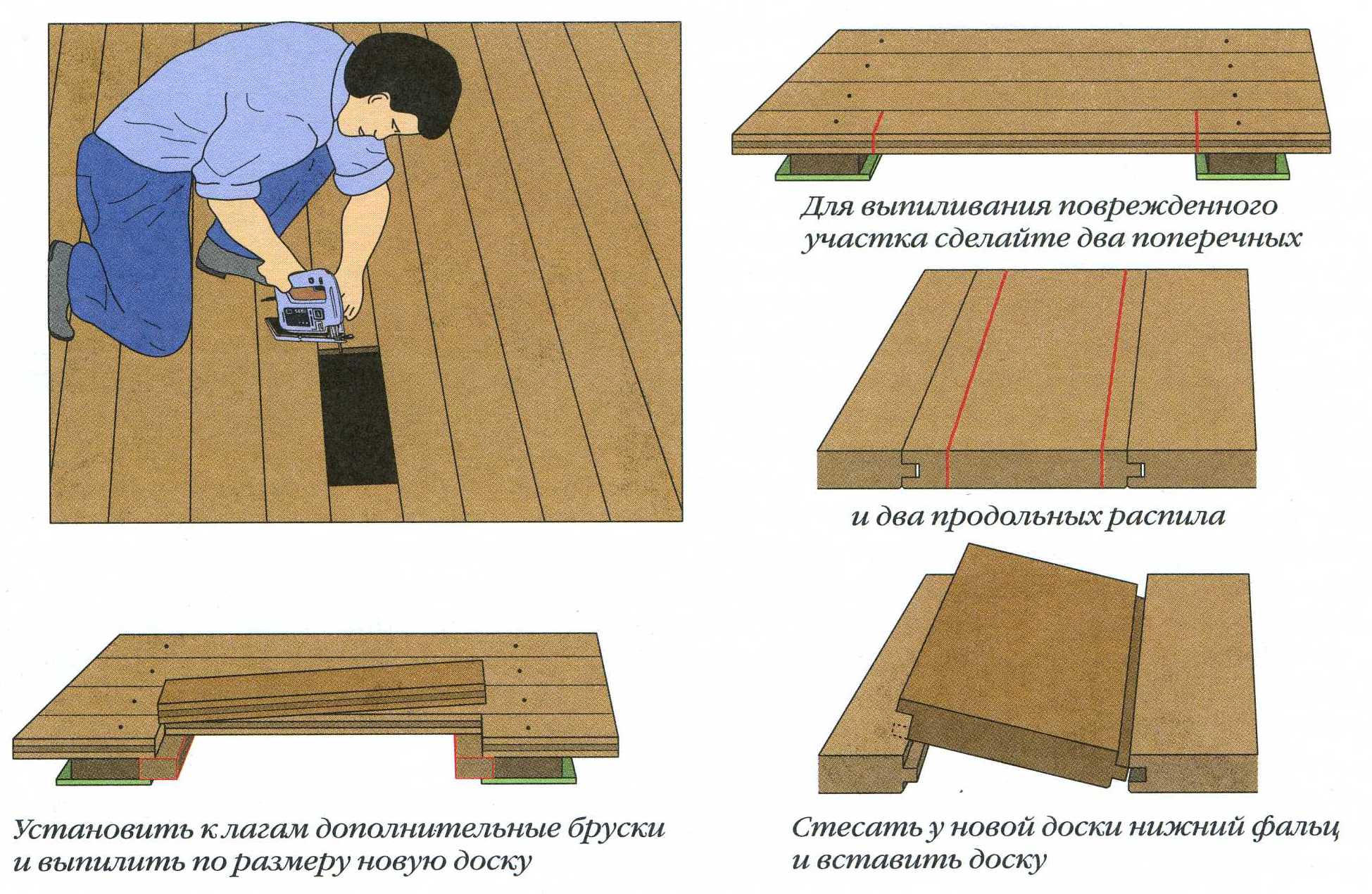

The treated surface is covered with varnish or oil. Scheme for replacing rotten parquet boards.The surface is thoroughly vacuumed to ensure absolutely uniform application of the varnish. It is necessary to apply 3-4 layers of varnish. Each new layer is applied only after the previous one has completely dried. This will take about 4 hours. Before varnishing, you can apply a primer or tinting composition to the wood surface. A roller is used to apply the varnish. The entire surface is covered with the composition at once. This must be done quickly enough, since the varnish sets almost immediately. After the first layer, the wood nap may rise. It can be removed by sanding, sandpaper No. 100 or 120. After this, all surfaces must be vacuumed again. Thus, do-it-yourself parquet sanding can be done efficiently only if all recommendations are followed. This work can take quite a lot of time, but it is better to do it longer than to redo everything later. Equipment for this can be rented.

Scheme for replacing rotten parquet boards.The surface is thoroughly vacuumed to ensure absolutely uniform application of the varnish. It is necessary to apply 3-4 layers of varnish. Each new layer is applied only after the previous one has completely dried. This will take about 4 hours. Before varnishing, you can apply a primer or tinting composition to the wood surface. A roller is used to apply the varnish. The entire surface is covered with the composition at once. This must be done quickly enough, since the varnish sets almost immediately. After the first layer, the wood nap may rise. It can be removed by sanding, sandpaper No. 100 or 120. After this, all surfaces must be vacuumed again. Thus, do-it-yourself parquet sanding can be done efficiently only if all recommendations are followed. This work can take quite a lot of time, but it is better to do it longer than to redo everything later. Equipment for this can be rented.