To restore the wooden floor covering, without perestilaya it, the cycle of parquet is made by own hands.  The scheme of the device of a parquet.

The scheme of the device of a parquet.

Main indications and contraindications

If the floor surface is evenly worn, it is baked. Cycle parquet is inappropriate in the following situations:

- the parquet has dried up;

- on the surface there are defects (determined visually);

- in the most trampled place from the surface of the boards to the dowel not more than 5 mm;

- there are bugs;

- the boards rot.

Scheme of parquet cake. Check the degree of mechanical wear helps the awl, vertically inserted into the crevices between the parquet until the tongue of the tongue. To fix the depth of penetration of the awl it is possible with the help of insulation for the electric wire or nail. Parquet coding is performed by means of special tools:

Scheme of parquet cake. Check the degree of mechanical wear helps the awl, vertically inserted into the crevices between the parquet until the tongue of the tongue. To fix the depth of penetration of the awl it is possible with the help of insulation for the electric wire or nail. Parquet coding is performed by means of special tools:

- surface grinding machine - grinds the surface before coating with varnish;

- Grinding drum machine - removes layers of old varnish and smooths the surface;

- Industrial vacuum cleaner - removes dust before coating with varnish;

- Angle grinder - cleans corners, edges and hard-to-reach areas under radiators.

From consumables you will need:

- disks for surface grinding machine;

- abrasive sandpaper;

- plaster parquet without filler;

- varnish of parquet.

Back to contents</a>

Manual Technique

The scheme of work of manual cycle. Experts advise to check the condition of the electrical wiring in the house, as the use of grinding machines will require 1.3-2.8 kW. The sound intensity of the instruments used is 110 dB. It is not recommended to replace the angle grinder with a grinder. The drum-type grinding machine "SO 206" is suitable only for stripping. Completed by this tool, fine grinding, despite 4 layers of varnish, leaves the parquet rough and dull. Machine cycle can be replaced with the restoration of the parquet with their own hands. The process does not require the skills of working with professional equipment, and dust can be removed from the surface before coating with varnish using a conventional vacuum cleaner, since fine chips are formed, rather than wood dust. Disadvantage: the beginner will need at least 12 hours to process 10 square meters. m. To uncrack the coating you will need an iron plane with a hook-like blade. The blade is heated for 10-15 minutes on a flame to a cherry glow and left to cool in the air. Then, together with a piece of pipe clamped in a vice and bend with frequent, light hammer blows. Straighten the blade is made on a circle or nazhdachkoy, and then hardened and cooled in water. Sharpening is made by removing the wedge from the outside of the bend. Productivity will increase, and labor costs will decrease if the work is done with a scraper, designed to clean up the seams of boards on small boats. The edges of the scrapers must be leveled with emery. Back to contents</a>

The scheme of work of manual cycle. Experts advise to check the condition of the electrical wiring in the house, as the use of grinding machines will require 1.3-2.8 kW. The sound intensity of the instruments used is 110 dB. It is not recommended to replace the angle grinder with a grinder. The drum-type grinding machine "SO 206" is suitable only for stripping. Completed by this tool, fine grinding, despite 4 layers of varnish, leaves the parquet rough and dull. Machine cycle can be replaced with the restoration of the parquet with their own hands. The process does not require the skills of working with professional equipment, and dust can be removed from the surface before coating with varnish using a conventional vacuum cleaner, since fine chips are formed, rather than wood dust. Disadvantage: the beginner will need at least 12 hours to process 10 square meters. m. To uncrack the coating you will need an iron plane with a hook-like blade. The blade is heated for 10-15 minutes on a flame to a cherry glow and left to cool in the air. Then, together with a piece of pipe clamped in a vice and bend with frequent, light hammer blows. Straighten the blade is made on a circle or nazhdachkoy, and then hardened and cooled in water. Sharpening is made by removing the wedge from the outside of the bend. Productivity will increase, and labor costs will decrease if the work is done with a scraper, designed to clean up the seams of boards on small boats. The edges of the scrapers must be leveled with emery. Back to contents</a>

Machine Work

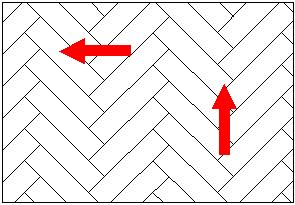

Scheme of the barking of the wooden floor. A special skin is used in the drum, it is necessary to fill it in the drum in accordance with the designation on it of the arrows. In the leased equipment, due to intensive exploitation, eccentrics are rotated to fix the skin. You can fix this if you put a spacer under them. The surface must be treated evenly and continuously so that no holes are formed in the floor. In the apparatus (before turning on), raise the discs or drum. The device starts up. Then you can start the movement of the machine, smoothly lowering the drum. Stop the unit in reverse order. Experts advise not to allow long processing of boards across the wood fibers to avoid chipping and scraping. To peel parquet from a straight-layer tree, laid with a "herringbone", it is necessary, tilting the equipment at an angle of 45º to the boards, and the finished polishing is made across and along. Perform all actions in 2 calls. Figured straight-layer parquet is polished in 2 mutually perpendicular directions 2 times. Decorative boards are processed smoothly in a spiral or in a circle, from the edge to the central part, using a surface grinding unit. Stripping is carried out, if necessary, in 2 sets. It is undesirable to linger on a hard-to-work area. Small-bed boards of decorative parquet from valuable species of wood are processed exclusively by professionals manually or in a circular motion by an angle grinder, smoothly moving it over the surface taking into account the pattern. Back to contents</a>

Scheme of the barking of the wooden floor. A special skin is used in the drum, it is necessary to fill it in the drum in accordance with the designation on it of the arrows. In the leased equipment, due to intensive exploitation, eccentrics are rotated to fix the skin. You can fix this if you put a spacer under them. The surface must be treated evenly and continuously so that no holes are formed in the floor. In the apparatus (before turning on), raise the discs or drum. The device starts up. Then you can start the movement of the machine, smoothly lowering the drum. Stop the unit in reverse order. Experts advise not to allow long processing of boards across the wood fibers to avoid chipping and scraping. To peel parquet from a straight-layer tree, laid with a "herringbone", it is necessary, tilting the equipment at an angle of 45º to the boards, and the finished polishing is made across and along. Perform all actions in 2 calls. Figured straight-layer parquet is polished in 2 mutually perpendicular directions 2 times. Decorative boards are processed smoothly in a spiral or in a circle, from the edge to the central part, using a surface grinding unit. Stripping is carried out, if necessary, in 2 sets. It is undesirable to linger on a hard-to-work area. Small-bed boards of decorative parquet from valuable species of wood are processed exclusively by professionals manually or in a circular motion by an angle grinder, smoothly moving it over the surface taking into account the pattern. Back to contents</a>

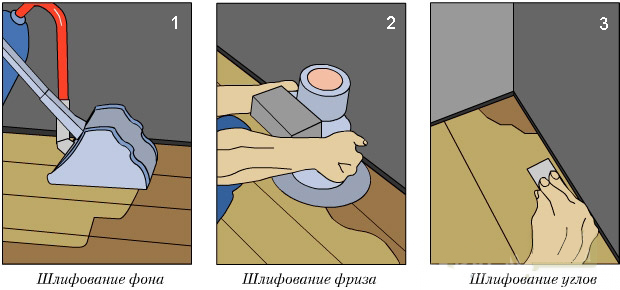

The main stages of restoration

Example of the floor before and after the cycle. Preliminarily the furniture is taken out of the room. Then the skirting board is dismantled and removed from the floor by a dry broom and a household vacuum cleaner. The next step is to fill the drum with R36-P40 and treat the entire surface 2 times. In this case, angles and hard-to-reach places are not affected. Processing starts from the far wall. Dust from the dust collector is collected in a plastic bag. Dark patches of old varnish in the corners and in hard-to-reach areas are removed by the angle grinder in a circular motion from the edges to the center. Stripping varnish in niches and corners with pendulum movements from the treated area to the wall. Then the basis of the putty is prepared and its uniform application to the entire floor surface with a spatula. Smoothing of boards with the equipment with a skin Р60-Р80 is carried out after drying шпаклевки. Lacquering and surface treatment is carried out after the drying of varnish or removal of wood pile with a surface grinder. You can not perform the restoration of parquet with the help of equipment without the occurrence of dust. Belt aggregates hold more dust, and using a respirator reduces the risk of lung disease. Carry out the restoration of the flooring yourself only if safety precautions are taken. It is necessary to protect eyes and respiratory organs from dust with the help of goggles and a respirator-petal, and hide your hair under a helmet or shawl. Headphones-stubs will help protect your ears from the high noise level of the equipment. Experts advise putting on clothes that are fastened to the throat from dense fabric, the cuffs of which should fit tightly around the hands to avoid getting the tiniest particles of varnish and wood on the body. Apply layers of varnish after completely drying the previous layer. The lacquer application tool is a microfibre roller, it can be used 1 time. Covering of plywood or a "parquet floor" laid with herringbone can not be polished to a mirror finish.

Example of the floor before and after the cycle. Preliminarily the furniture is taken out of the room. Then the skirting board is dismantled and removed from the floor by a dry broom and a household vacuum cleaner. The next step is to fill the drum with R36-P40 and treat the entire surface 2 times. In this case, angles and hard-to-reach places are not affected. Processing starts from the far wall. Dust from the dust collector is collected in a plastic bag. Dark patches of old varnish in the corners and in hard-to-reach areas are removed by the angle grinder in a circular motion from the edges to the center. Stripping varnish in niches and corners with pendulum movements from the treated area to the wall. Then the basis of the putty is prepared and its uniform application to the entire floor surface with a spatula. Smoothing of boards with the equipment with a skin Р60-Р80 is carried out after drying шпаклевки. Lacquering and surface treatment is carried out after the drying of varnish or removal of wood pile with a surface grinder. You can not perform the restoration of parquet with the help of equipment without the occurrence of dust. Belt aggregates hold more dust, and using a respirator reduces the risk of lung disease. Carry out the restoration of the flooring yourself only if safety precautions are taken. It is necessary to protect eyes and respiratory organs from dust with the help of goggles and a respirator-petal, and hide your hair under a helmet or shawl. Headphones-stubs will help protect your ears from the high noise level of the equipment. Experts advise putting on clothes that are fastened to the throat from dense fabric, the cuffs of which should fit tightly around the hands to avoid getting the tiniest particles of varnish and wood on the body. Apply layers of varnish after completely drying the previous layer. The lacquer application tool is a microfibre roller, it can be used 1 time. Covering of plywood or a "parquet floor" laid with herringbone can not be polished to a mirror finish.