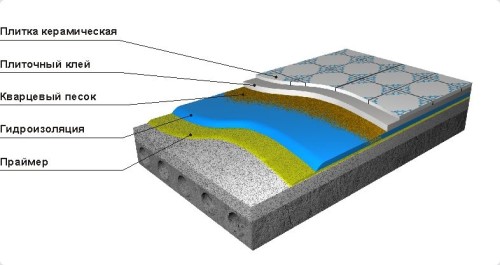

Floor waterproofing is the most important stagework when arranging a house. If a person cannot do without moisture, then the structure of the house, and especially the floor, can and should be without liquid, since for some elements its presence will be destructive. Therefore, the question of how to make waterproofing of the floor is important. Floor waterproofing scheme under tiles.

Floor waterproofing scheme under tiles.

Features of floor waterproofing

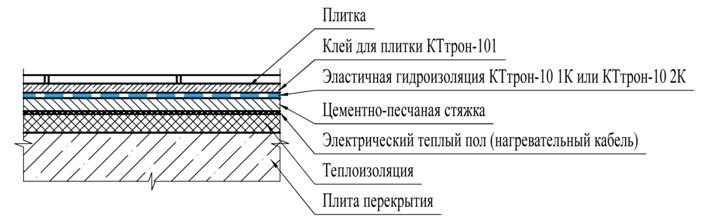

If the apartment has a considerable service life,then there is no need to talk about the quality of the floors. The situation is simpler if the base of the floor is reinforced concrete. In this case, it is necessary to dismantle the old floors down to the concrete base. If the base is wooden, then the owner of the house faces many problems. Wood is a fragile material, it can easily become damp and begin to crumble, which raises the question of replacing the entire floor. As for reinforced concrete flooring, there are several pieces of advice applicable to it. The first of them says that special attention should be paid to those places where there is a zone of high humidity. In this case, it is necessary to replace the flooring down to the base. Floor waterproofing scheme in the kitchen and bathroomroom. Next, it is recommended to level the floor with a self-leveling mixture or a special repair compound. It is worth noting that trying to get rid of unevenness with waterproofing is stupid, just like using roll coatings and self-leveling floors. If you want to redesign the rooms, you should remove all interfering partitions. This is due to the fact that when waterproofing, it is necessary to maintain tightness, for which it is recommended to apply the coating entirely. It will be difficult to carry out this work under partitions. In addition, it is not recommended to carry out partial insulation, as this will reduce all the money and effort spent to a negative result. Water can get into unprotected areas, which will require additional repairs. For rooms such as a bathroom or kitchen, where water can easily get on the floor, there are a number of tricks. To prevent liquid from getting, for example, from a kitchen protected by waterproofing to another room where there is no protection, during construction, the kitchen floor is made slightly lower than the level of other rooms. If this is not possible, then you can get by with a small border between the rooms, which will stop moisture. Return to Contents</a>

Floor waterproofing scheme in the kitchen and bathroomroom. Next, it is recommended to level the floor with a self-leveling mixture or a special repair compound. It is worth noting that trying to get rid of unevenness with waterproofing is stupid, just like using roll coatings and self-leveling floors. If you want to redesign the rooms, you should remove all interfering partitions. This is due to the fact that when waterproofing, it is necessary to maintain tightness, for which it is recommended to apply the coating entirely. It will be difficult to carry out this work under partitions. In addition, it is not recommended to carry out partial insulation, as this will reduce all the money and effort spent to a negative result. Water can get into unprotected areas, which will require additional repairs. For rooms such as a bathroom or kitchen, where water can easily get on the floor, there are a number of tricks. To prevent liquid from getting, for example, from a kitchen protected by waterproofing to another room where there is no protection, during construction, the kitchen floor is made slightly lower than the level of other rooms. If this is not possible, then you can get by with a small border between the rooms, which will stop moisture. Return to Contents</a>

Types of materials for insulation

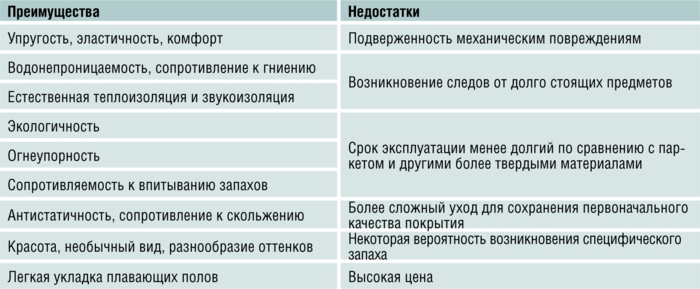

Table of requirements for waterproofing installationfloors made of roll materials. It is important not only to know how to properly waterproof a floor, but also to choose the right material for the job. There are a lot of them at the moment, so it is worth telling about them. Materials for waterproofing floors are divided into several categories:

Table of requirements for waterproofing installationfloors made of roll materials. It is important not only to know how to properly waterproof a floor, but also to choose the right material for the job. There are a lot of them at the moment, so it is worth telling about them. Materials for waterproofing floors are divided into several categories:

If you plan to do waterproofingindependently, it is recommended to use special plasters or coating agents. Rolled agents are also suitable for independent work, but they are difficult to attach and lay if you work on your own. Waterproofing of the floor using penetrating agents can also be done by yourself, but for this you should follow all the instructions for laying and care in the future. In addition, it is necessary to do some procedures. It is worth noting that the use of such agents during insulation should be combined with moisturizing, which can lead to leakage during work. Scheme of bulk type insulation.The bulk type of insulation is used under the screed. The material is represented by special granules that have one feature - when moisture gets on them, the material begins to foam, resulting in the formation of a gel. This gel does not allow moisture to pass further. As for sprayed polymers, it is difficult to make a coating with such insulation on your own. This is explained by the fact that a large number of rules and requirements must be followed to lay the material, which without knowledge and skills can lead to a negative result. Therefore, it is not recommended to try to carry out such insulation without special knowledge and skills. It is also worth mentioning some misconceptions. Surfaces such as floor tiles are not considered insulation. Even if polyurethane or silicone grout required for seams was used during its installation, you should not rely on the protection of such a surface. As for the bathroom, even with waterproofing of the floor, moisture can penetrate below, as it tends to collect on the walls and penetrate other surfaces. Return to contents</a>

Scheme of bulk type insulation.The bulk type of insulation is used under the screed. The material is represented by special granules that have one feature - when moisture gets on them, the material begins to foam, resulting in the formation of a gel. This gel does not allow moisture to pass further. As for sprayed polymers, it is difficult to make a coating with such insulation on your own. This is explained by the fact that a large number of rules and requirements must be followed to lay the material, which without knowledge and skills can lead to a negative result. Therefore, it is not recommended to try to carry out such insulation without special knowledge and skills. It is also worth mentioning some misconceptions. Surfaces such as floor tiles are not considered insulation. Even if polyurethane or silicone grout required for seams was used during its installation, you should not rely on the protection of such a surface. As for the bathroom, even with waterproofing of the floor, moisture can penetrate below, as it tends to collect on the walls and penetrate other surfaces. Return to contents</a>

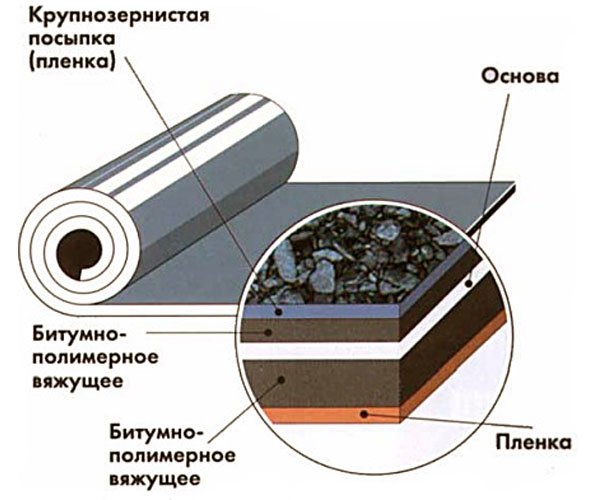

Waterproofing with roll materials

Layers of waterproofing material. The following tools are required for the work:

Layers of waterproofing material. The following tools are required for the work:

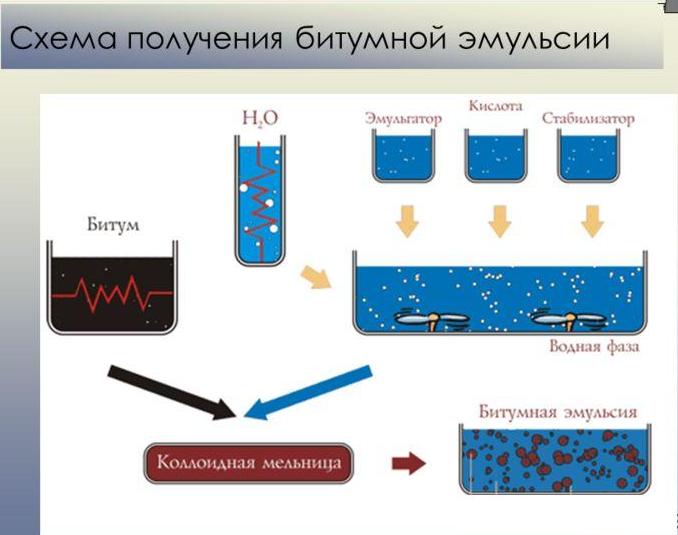

Before using this method,it is necessary to completely level the floor. This is due to the fact that there should be no free space between the insulation layer and the floor surface. For leveling, you should use a self-leveling compound, as it is best suited for this type of work. After that, you need to clean the floor surface from debris and dust. This work can be done with a vacuum cleaner or simply sweeping. To ensure better adhesion of the material to the floor, the latter must be primed. The mixture must be diluted with water or a special compound, which depends on the material used. The resulting mixture must be poured onto the floor. For better and more uniform distribution of the mixture over the entire surface, it is recommended to use a roller with a needle attachment. In addition, the use of this roller will get rid of air bubbles that may form during pouring. According to the basic rules of the process, insulation using adhesive materials is carried out on special-purpose glue or bitumen mastic. In addition, it is recommended to use polyisobutylene, PVC film or fiberglass on polymer mastic, while on bitumen - hydrostekloizol, hydroisol and brizol. Summarizing all of the above, it is necessary to repeat that the floor is cleaned before waterproofing, after which it is treated with bitumen emulsion. Scheme for obtaining bitumen emulsion.The emulsion does not emit harmful solvents during operation, as it is made on the basis of water. The primer is applied in two layers, both should be perpendicular to each other. While the first layer has not yet dried, it is necessary to glue the joints and corners with tape. The next layer should be well coated with these places. After some time, which is necessary for the drying of the primer layer, you can start working. How to properly make waterproofing in this case? It is necessary to simply glue layers of material to the surface. If self-adhesive carpets are used, they must be pressed to the floor. As for ordinary carpets, when using them, it is recommended to use a building hair dryer or a burner. The lower surface of the outer layer is melted, after which it is pressed to the floor surface. The places where the strips overlap must also be melted, and then welded together. An overlap of material should be made on the walls, approximately 20 cm. After the screed is completed, these pieces should be removed. Additional patches should be used to seal the corners, after which the sealing should be done well. Return to contents</a>

Scheme for obtaining bitumen emulsion.The emulsion does not emit harmful solvents during operation, as it is made on the basis of water. The primer is applied in two layers, both should be perpendicular to each other. While the first layer has not yet dried, it is necessary to glue the joints and corners with tape. The next layer should be well coated with these places. After some time, which is necessary for the drying of the primer layer, you can start working. How to properly make waterproofing in this case? It is necessary to simply glue layers of material to the surface. If self-adhesive carpets are used, they must be pressed to the floor. As for ordinary carpets, when using them, it is recommended to use a building hair dryer or a burner. The lower surface of the outer layer is melted, after which it is pressed to the floor surface. The places where the strips overlap must also be melted, and then welded together. An overlap of material should be made on the walls, approximately 20 cm. After the screed is completed, these pieces should be removed. Additional patches should be used to seal the corners, after which the sealing should be done well. Return to contents</a>

Lubricating protection method

Coating polymer cement waterproofing of the floor. To perform the work, you need to have the following tools:

Coating polymer cement waterproofing of the floor. To perform the work, you need to have the following tools:

This method is simple because it requiresit is not necessary to have perfectly flat floors, use sprayers and burners, have special skills and abilities, equipment. As in the previous method, you should clean the floor from dirt, prime the surface, and glue the corners and joints using sealing tape. Then you need to knead the mastic, mixing is carried out until it acquires the state of thick sour cream. The powder is added to the water, the solution must be thoroughly mixed again. After this, you can start working, for which you will need a brush, which should be used to apply the material. The insulation is applied to the floor, you need to grab a little and the walls, about 30 cm. The composition is thoroughly rubbed into the surfaces, you do not need to smear it, but there should be no puddles either. As soon as the first layer begins to set, it must be moistened and proceed to applying the second layer. It is applied perpendicular to the initial layer. The total number of layers can reach five, but three layers are enough. This indicator depends on the degree of curvature of the surface. Thus, when starting work, you need to know how to properly make waterproofing. Even such a simple method as coating should be carried out in accordance with the rules, so as not to have to pay for poorly done work.