There are situations when owners of smallapartments are faced with the problem of lack of space. And if the family is large, then the need for additional storage space increases. Buying ready-made furniture may not always be a way out of this situation, since it is not always able to fit into an already finished interior. And the cost of making custom furniture can be quite high. There is a very worthy alternative to traditional furniture - plasterboard cabinets and shelves. It is quite possible to make a cabinet from plasterboard yourself. Below is an instruction on how to make a cabinet from plasterboard sheets. You can make an inexpensive and practical wardrobe from plasterboard and metal profiles.

You can make an inexpensive and practical wardrobe from plasterboard and metal profiles.

Features and benefits of plasterboard cabinets

The main advantages of cabinets made from plasterboard sheets:

- relatively low cost;

- convenience and practicality;

- the creation of an exclusive cabinet design that perfectly fits into the style of your interior.

- the plasterboard material itself is environmentally friendly, non-toxic, non-radioactive, with good thermal insulation; except for conventional GCR, there are still moisture-resistant and fire-resistant sheets;

- GCR can be painted, plastered, wallpapered and tiled;

- in furniture from GKL it is possible to build in lighting.

Metal profiles for plasterboard installation.One of the rational and practical solutions for creating a wardrobe from plasterboard is a sliding wardrobe. Such a wardrobe has many useful features and in many cases even surpasses custom-made wardrobes, since their cost is much higher. When the wardrobe from plasterboard is ready, it is enough to order sliding doors from the craftsmen. However, if you decide to make a wardrobe from plasterboard, it is important to know a number of features of such furniture:

Metal profiles for plasterboard installation.One of the rational and practical solutions for creating a wardrobe from plasterboard is a sliding wardrobe. Such a wardrobe has many useful features and in many cases even surpasses custom-made wardrobes, since their cost is much higher. When the wardrobe from plasterboard is ready, it is enough to order sliding doors from the craftsmen. However, if you decide to make a wardrobe from plasterboard, it is important to know a number of features of such furniture:

Return to Contents</a>

Development of cabinet design

Tools for working with plasterboard.Work on creating a plasterboard cabinet begins with developing a sketch of its appearance, and then a drawing of the structure with all the dimensions. To do this, it is necessary to take measurements of the place where you plan to build the cabinet, and based on the obtained dimensions, develop an accurate design scheme. For beginners, these can be simple rectangular and square shapes. But if you decide on a more original design with curved asymmetrical shapes, then such a cabinet will look much more interesting. Return to contents</a>

Tools for working with plasterboard.Work on creating a plasterboard cabinet begins with developing a sketch of its appearance, and then a drawing of the structure with all the dimensions. To do this, it is necessary to take measurements of the place where you plan to build the cabinet, and based on the obtained dimensions, develop an accurate design scheme. For beginners, these can be simple rectangular and square shapes. But if you decide on a more original design with curved asymmetrical shapes, then such a cabinet will look much more interesting. Return to contents</a>

Assembling the frame of the cabinet

When will the drywall cabinet project be completed?fully developed, all errors and inaccuracies are checked and corrected, you can start assembling its frame. To install a plasterboard cabinet, you will need quite a large number of materials and tools. Materials: Fasteners for a plasterboard cabinet: 1 - dowel-nail, 2 - snail, 3 - butterfly, 4 - anchor screw, 5 - anchor bolt.

Fasteners for a plasterboard cabinet: 1 - dowel-nail, 2 - snail, 3 - butterfly, 4 - anchor screw, 5 - anchor bolt.

- GKL is normal or moisture resistant;

- metal profiles UD and CD;

- plastic or metal corners to protect the GCR;

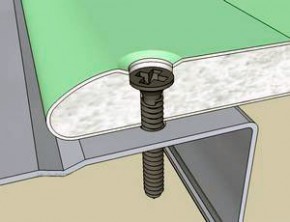

- Self-tapping screws for fastening metal profiles and gypsum boards;

- Painting mesh;

- finishing putty;

- primer;

- Finishing material (paint, decorative plaster, etc.);

- Furniture fittings (if necessary);

- fixtures, switches, sockets and cables for them (if necessary).

Tools:

- perforator or electric drill;

- Screwdriver;

- Bulgarian;

- scissors for metal;

- paint knife;

- ruler, square, pencil;

- building level;

- edge planer;

- a set of putty knives;

- Grater and sandpaper for grinding;

- paint rolls, brushes;

- containers for solutions.

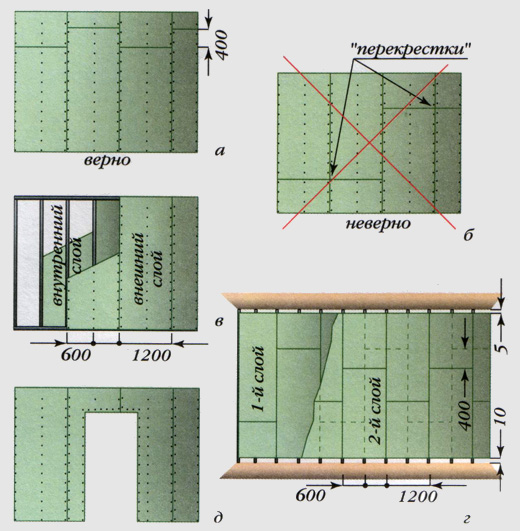

To make the frame, metal profiles are most often used, and less often, wooden beams. Scheme of correct joining of plasterboard sheets.A wooden frame requires careful selection of material, as its quality will affect the final result. If you decide to opt for a frame made of wooden beams, then when choosing it, pay attention to its condition and appearance. The wood must be completely dry, having completely shrunk. Otherwise, the wooden frame will shrink, which will lead to its deformation. Accordingly, the sheets of drywall will also be deformed and may even crack. Therefore, it is better to opt for metal profiles. Assembling a metal frame is much easier and simpler, especially if you are a beginner in this matter. Wooden beams can only be used in places that require increased strength, since in this matter, wooden beams are stronger than metal ones. Frame assembly stages:

Scheme of correct joining of plasterboard sheets.A wooden frame requires careful selection of material, as its quality will affect the final result. If you decide to opt for a frame made of wooden beams, then when choosing it, pay attention to its condition and appearance. The wood must be completely dry, having completely shrunk. Otherwise, the wooden frame will shrink, which will lead to its deformation. Accordingly, the sheets of drywall will also be deformed and may even crack. Therefore, it is better to opt for metal profiles. Assembling a metal frame is much easier and simpler, especially if you are a beginner in this matter. Wooden beams can only be used in places that require increased strength, since in this matter, wooden beams are stronger than metal ones. Frame assembly stages:

Return to Contents</a>

Gypsum board casing

After the cabinet frame is fully assembled, you canproceed to covering it with plasterboard. The frame should be covered from the outside and inside. However, if the cabinet is small, then it is quite possible to do with covering from the outside. It should be remembered that the larger the cabinet, the greater the load will be on its internal shelves and walls. Therefore, it can be covered with 2 layers of plasterboard. Fastening plasterboard sheets to the profiles is carried out similarly to installing plasterboard when cladding walls and ceilings: Scheme of fastening gypsum board with screws.

Scheme of fastening gypsum board with screws.

Return to Contents</a>

Putty and finish of the cabinet

Next comes the preparation of the cabinet for finishing.— plasterboard putty. All screw holes and joints between sheets need to be puttyed. To do this, a special painting mesh is glued to the joints, after which they are puttyed. After the putty has dried, the surface must be sanded and primed. If necessary, apply a second layer of putty and sand and prime again. After the primer has completely dried, the surface is ready for finishing. Drywall cabinets are good because they can be made in the bathroom, using moisture-resistant drywall. In this case, the surface of the shelves and walls of the cabinet can be covered with ceramic tiles or mosaics. To do this, it is enough to just putty the joints between the drywall sheets, prime all surfaces of the cabinet and start laying the tiles.</ ul>