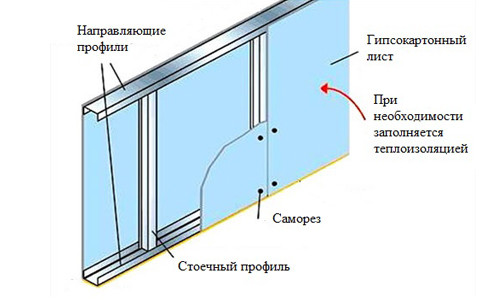

Plasterboard sheets are cheap and veryconvenient material for self-assembly. With their help, you can build partitions, arches, niches and other architectural elements. And all these details require further finishing. There is nothing complicated in such work. But puttying plasterboard walls requires a competent and verified approach. Otherwise, cracks and other defects may appear on the surface in the future, which can be difficult to eliminate. Scheme of the device of a wall from plasterboard.

Scheme of the device of a wall from plasterboard.

Selection of material for wall treatment

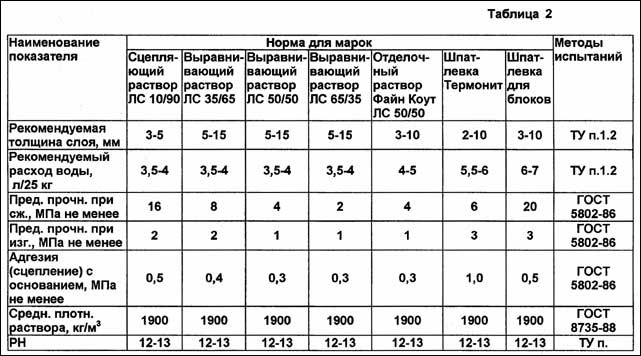

It is impossible to assemble the structure so that betweenthere are no joints or seams left between the sheets of plasterboard. In addition, drilled holes, mounting units and places where fasteners are installed require mandatory processing. But in order for the result of your work to be reliable and durable, it is necessary to choose the right finishing material. In modern stores, you can find 3 main types of putty intended for plasterboard. These are compositions made on the basis of cement, gypsum and polymers. All 3 types are suitable for eliminating defects in structures assembled from gypsum board. The choice must be made based on the purpose of the room being repaired. Polymer compositions are universal. They can be used in bathrooms, kitchens and living spaces. The consumption of such putty is minimal. But this material has a significant drawback. As a rule, such compositions are much more expensive than their analogues. Table of characteristics of putty solutions.Cement putty is the cheapest, but it is not suitable for finishing walls in rooms with high humidity. And when drying, the material may crack at the joints of the plasterboard sheets. You should not choose materials based on advertising and additional characteristics of the composition. Such parameters as fire resistance and frost resistance do not play a big role when finishing the interior. But they significantly affect the cost of the product. Return to the table of contents</a>Selection of material by composition Putty for plasterboard walls can be divided into the following types:

Table of characteristics of putty solutions.Cement putty is the cheapest, but it is not suitable for finishing walls in rooms with high humidity. And when drying, the material may crack at the joints of the plasterboard sheets. You should not choose materials based on advertising and additional characteristics of the composition. Such parameters as fire resistance and frost resistance do not play a big role when finishing the interior. But they significantly affect the cost of the product. Return to the table of contents</a>Selection of material by composition Putty for plasterboard walls can be divided into the following types:

- Designed for finishing different surfaces (horizontal or vertical);

- mixture to eliminate small defects (chips, cracks);

- decorative materials.

When processing walls on the first characteristicyou can ignore it. As a rule, special putties are purchased when installing floors. And plasterboard is rarely used for such purposes. The other 2 types are needed only for finishing structures. For primary processing, you need the simplest composition. It is easiest to putty plasterboard walls yourself using dry materials. Tools for wall puttying.Using such mixtures will allow you to prepare exactly the amount of the composition that is needed at the moment, since this material dries quickly in the open air and becomes unsuitable for further work. Give preference to mixtures that are labeled as universal. Before buying putty, pay attention to the packaging. It should be intact and without visible damage. It is wiser to buy powder packaged in plastic bags or jars, since paper packaging, even treated with water-repellent impregnation, can get wet during transportation. Return to contents</a>Preliminary priming of walls Beforeputty the walls, all surfaces must be carefully primed. This must be done regardless of what decorative coating you have chosen for further work. A high-quality primer forms a special film that will protect the drywall sheets from moisture, wallpaper glue or paint. Structures assembled from gypsum board are treated with water-soluble mixtures. They impregnate the top coating of the sheet, but are not able to penetrate inside it. Thus, the integrity of the drywall is preserved, and its surface becomes protected. In addition, the primer provides additional adhesion of the putty to the wall. Experts do not recommend using primers made on an alkyd basis. Their use leads to deformation of the drywall. The wet paper layer separates from the plaster, swells with bubbles and delaminates. And puttying the walls will not eliminate such defects. The mixture is applied to the structure, pre-cleaned from dust and dirt. Plasterboard walls must be puttied carefully, keeping the room clean, as fine dust can form lumps, which will make the surface uneven.

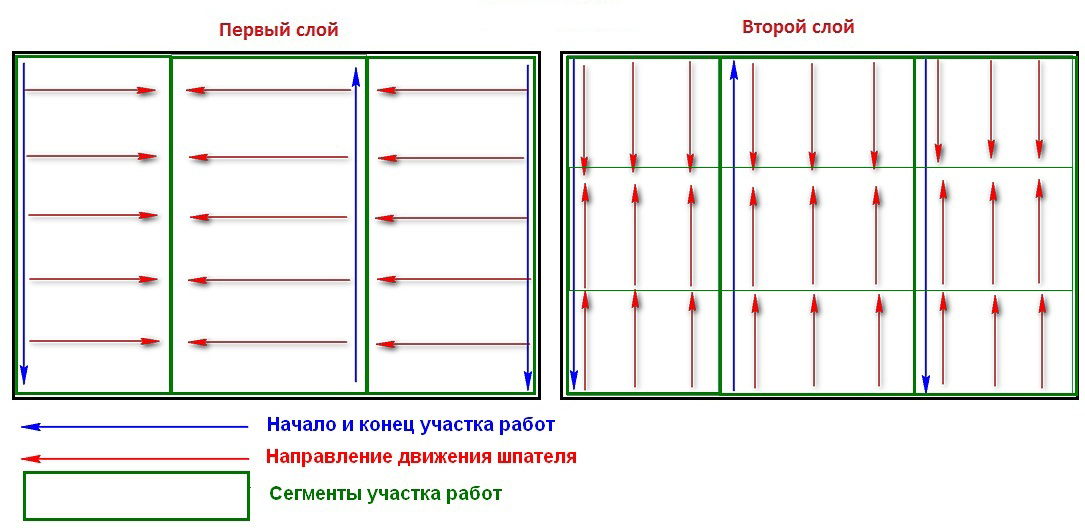

Tools for wall puttying.Using such mixtures will allow you to prepare exactly the amount of the composition that is needed at the moment, since this material dries quickly in the open air and becomes unsuitable for further work. Give preference to mixtures that are labeled as universal. Before buying putty, pay attention to the packaging. It should be intact and without visible damage. It is wiser to buy powder packaged in plastic bags or jars, since paper packaging, even treated with water-repellent impregnation, can get wet during transportation. Return to contents</a>Preliminary priming of walls Beforeputty the walls, all surfaces must be carefully primed. This must be done regardless of what decorative coating you have chosen for further work. A high-quality primer forms a special film that will protect the drywall sheets from moisture, wallpaper glue or paint. Structures assembled from gypsum board are treated with water-soluble mixtures. They impregnate the top coating of the sheet, but are not able to penetrate inside it. Thus, the integrity of the drywall is preserved, and its surface becomes protected. In addition, the primer provides additional adhesion of the putty to the wall. Experts do not recommend using primers made on an alkyd basis. Their use leads to deformation of the drywall. The wet paper layer separates from the plaster, swells with bubbles and delaminates. And puttying the walls will not eliminate such defects. The mixture is applied to the structure, pre-cleaned from dust and dirt. Plasterboard walls must be puttied carefully, keeping the room clean, as fine dust can form lumps, which will make the surface uneven. Sequence of wall puttying.Therefore, the wall should not only be wiped with a rag, but also cleaned with a soft brush. The primer is applied over the entire surface. Pay special attention to the treatment of corners and joints of the wall with the ceiling and floor. The product must be applied in 2 layers, allowing the previous one to dry completely. The thickness of one layer of primer should not be less than 0.03-0.05 mm. Return to contents</a>

Sequence of wall puttying.Therefore, the wall should not only be wiped with a rag, but also cleaned with a soft brush. The primer is applied over the entire surface. Pay special attention to the treatment of corners and joints of the wall with the ceiling and floor. The product must be applied in 2 layers, allowing the previous one to dry completely. The thickness of one layer of primer should not be less than 0.03-0.05 mm. Return to contents</a>

Treatment of plasterboard walls

Plastering of plasterboard walls begins withprocessing of joints and nests of fasteners (heads of screws). It is necessary to take care of the smoothness of the surface at the stage of installation of the entire structure. The heads of the fasteners should not rise above the surface. But they should not be sunk either. Otherwise, a recess will form in this place, which will need to be sealed. To carry out the work, you will need the following tools:

- capacity for breeding the composition (most convenient special cuvettes);

- wide metal spatulas;

- small rubber spatulas for processing joints;

- Master OK;

- grater;

- scissors or sharp clerical knife.

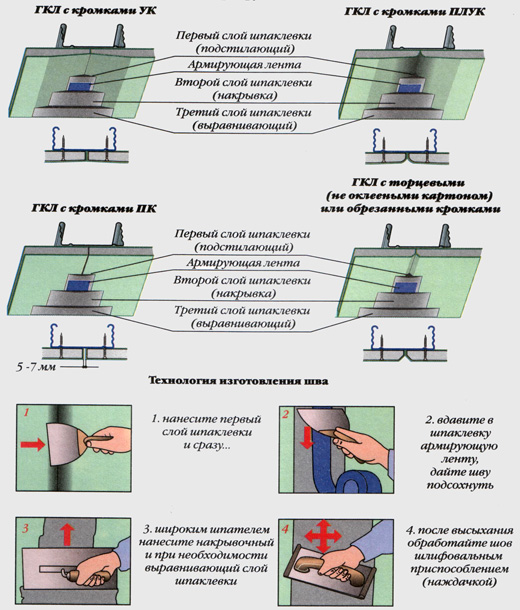

If you are using a dry mix, this will come in handy.also a bucket for mixing putty and a mixer attachment for a drill. Don't forget to buy a special fiberglass tape (called serpyanka). It is necessary for strengthening joints and seams. Scheme of processing plasterboard seams.If the plasterboard sheets do not have an edge, it must be formed. To do this, cut the edges of the joints on both sides at an angle of 45 °. Then, use a small spatula to collect the putty and apply it to the seam. Stretch the composition with a wider tool along the entire length of the wall, reliably sealing the gap. Next, apply serpyanka to all seams and corners. It has adhesive properties, so it does not need additional fixation. Position the tape so that its middle falls on the center of the joint of the sheets. After this, apply another layer of the product, level the joint flush with the wall. To seal the heads of the fasteners, apply the putty crosswise. First, run a small rubber spatula along the head of the screw, and then across. This method allows you to evenly fill all the grooves and recesses with the mass. Finishing walls made of plasterboard requires paying special attention to the corners of the structure. They are finished in 2 steps. First, one wall is processed, and only after the composition has dried can the other one be puttied. But what to do if drips and runs have formed during the work? In this case, you need to wait until the composition has completely dried and remove the resulting defect using fine-grained sandpaper. The surface must be processed extremely carefully. Otherwise, there is a high risk of damaging not only the putty layer, but also the sheet itself. Return to contents</a>Finishing of walls In order to puttydoes not crumble at the outer corners of the structure, it is reinforced with special corners. They are made of aluminum and equipped with a reinforcing mesh. They frame window and door openings, protruding parts of piers and partitions. Such corners are attached with ordinary self-tapping screws. After the structure is secured, they begin to fill the mesh cells with putty. For this, you will need a small spatula. They collect a small amount of the product and putty all the voids. And only after the recesses are leveled, the mass is stretched and leveled over the entire surface with a large wide tool. Make sure that the edge of the corner does not protrude above the main plane of the sheet. Sometimes you have to apply a fairly thick layer of putty for this. The edges of the arches are decorated with a flexible plastic corner. It is slightly thicker than its metal counterpart. It is fixed with a furniture stapler, and the surface is leveled in two steps. Each previous layer of putty should dry completely. Do not try to apply a thick layer of the mass at once. This will lead to a defect in the surface. When drying, the composition will sink into the voids that inevitably arise when applying a large amount of putty. In this case, the wall will be uneven. After all the finished surfaces are completely dry, small irregularities are removed with sandpaper and the final layer of the composition is applied. For this, the product is diluted to the consistency of sour cream. This will allow it to be applied to the wall in an even and smooth layer.

Scheme of processing plasterboard seams.If the plasterboard sheets do not have an edge, it must be formed. To do this, cut the edges of the joints on both sides at an angle of 45 °. Then, use a small spatula to collect the putty and apply it to the seam. Stretch the composition with a wider tool along the entire length of the wall, reliably sealing the gap. Next, apply serpyanka to all seams and corners. It has adhesive properties, so it does not need additional fixation. Position the tape so that its middle falls on the center of the joint of the sheets. After this, apply another layer of the product, level the joint flush with the wall. To seal the heads of the fasteners, apply the putty crosswise. First, run a small rubber spatula along the head of the screw, and then across. This method allows you to evenly fill all the grooves and recesses with the mass. Finishing walls made of plasterboard requires paying special attention to the corners of the structure. They are finished in 2 steps. First, one wall is processed, and only after the composition has dried can the other one be puttied. But what to do if drips and runs have formed during the work? In this case, you need to wait until the composition has completely dried and remove the resulting defect using fine-grained sandpaper. The surface must be processed extremely carefully. Otherwise, there is a high risk of damaging not only the putty layer, but also the sheet itself. Return to contents</a>Finishing of walls In order to puttydoes not crumble at the outer corners of the structure, it is reinforced with special corners. They are made of aluminum and equipped with a reinforcing mesh. They frame window and door openings, protruding parts of piers and partitions. Such corners are attached with ordinary self-tapping screws. After the structure is secured, they begin to fill the mesh cells with putty. For this, you will need a small spatula. They collect a small amount of the product and putty all the voids. And only after the recesses are leveled, the mass is stretched and leveled over the entire surface with a large wide tool. Make sure that the edge of the corner does not protrude above the main plane of the sheet. Sometimes you have to apply a fairly thick layer of putty for this. The edges of the arches are decorated with a flexible plastic corner. It is slightly thicker than its metal counterpart. It is fixed with a furniture stapler, and the surface is leveled in two steps. Each previous layer of putty should dry completely. Do not try to apply a thick layer of the mass at once. This will lead to a defect in the surface. When drying, the composition will sink into the voids that inevitably arise when applying a large amount of putty. In this case, the wall will be uneven. After all the finished surfaces are completely dry, small irregularities are removed with sandpaper and the final layer of the composition is applied. For this, the product is diluted to the consistency of sour cream. This will allow it to be applied to the wall in an even and smooth layer.