If in an old building the creaking of floorboards allowsfeel the spirit of previous centuries, exciting the imagination, then in a modern apartment it can be as annoying as a toothache. This is a problem with many wooden bases. You have to carefully choose the place where you can step. If replacing the bases for some reason is impossible or simply undesirable, there is only one way out - repair. Over time, any wooden floor begins tocreaking, but you can get rid of this problem without major repairs. In the old days, a proven way to combat this phenomenon was to rub the seams between the boards with a wax candle. It is still used today, replacing wax with paraffin or pouring graphite powder or talc into the cracks between the floorboards. Sometimes this helps, but usually not for long. Nevertheless, there are ways to reliably and permanently get rid of it without major repairs or re-laying. Below, these methods are systematized.

Over time, any wooden floor begins tocreaking, but you can get rid of this problem without major repairs. In the old days, a proven way to combat this phenomenon was to rub the seams between the boards with a wax candle. It is still used today, replacing wax with paraffin or pouring graphite powder or talc into the cracks between the floorboards. Sometimes this helps, but usually not for long. Nevertheless, there are ways to reliably and permanently get rid of it without major repairs or re-laying. Below, these methods are systematized.

How to get rid of scratches floorboards without major repairs?

It would seem that there could be any number of reasons why unpleasant sounds occur when moving across the floor. But in reality, there are not so many:

- the movement of the floorboards and the ends of the logs with respect to each other;

- no gap between floorboards and walls;

- The nail or self-tapping shook or went out of its nest;

- drying of logs or floorboards;

- breakage of the groove or protrusion of the floorboard.

Tools and materials that may be needed for work: Floor repair tools.

Floor repair tools.

- hammer and nail;

- self-tapping screws;

- wedges and cork from wood;

- large-plywood plywood or gypsum-fiber sheet (GVL);

- adhesive PVA, sealant, assembly foam, putty;

- synthetic rope, wooden sawdust and shavings.

The easiest way to get rid of a creaking floor iscaused by loose nails rubbing against the wood. Such nails are pulled out and screws are screwed in instead, which cannot loosen and creak. It is worth dwelling on other methods of fixing creaky floors in more detail. Return to contents</a>Floor repair using wedgesAs a result of shrinkage of the floorboards and joists, a gap may appear between them. Due to friction of the boards against the joists, a squeak appears. This problem can be eliminated by driving wooden wedges into the gap between the boards and joists. It should be noted that this method is not the most rational and is quite labor-intensive. To get to the defect, you will have to remove the adjacent board, which then needs to be put back in place. As a result, double the work will be done. Nevertheless, such a method exists. Instead of wedges, mounting foam is sometimes used. This method is less reliable. The fact is that, due to pressure, the mounting foam quickly collapses and sags. Return to contents</a>Using Screws to Repair Floors The process of eliminating creaking on a wooden floor.This method allows you to repair a creaking floor without disassembling it. It gives a good effect and does not require significant material costs. The first thing to do is to determine the distance from the upper floor level to the concrete floor. To do this, drill a small hole in the floorboard in one of the places where the sound is coming from. By inserting a strong wire into it, you can measure the distance to the concrete. The screws, the number of which should correspond to the number of creaking areas, should be longer than the measured distance. A screw is screwed into the drilled hole. This should be done carefully, especially near the concrete floor. The screw should create support, and not raise the floor. It is better if the screws reach the concrete, passing through the joists. The described operation is repeated in all those places where the creaking is heard. In order not to get hurt on the protruding sections of the screws, it is better to temporarily cover them with jars of suitable height. When all the screws are installed in their intended places, you should check if there are any more creaking areas of the floor. If necessary, loosen or tighten some screws. After checking and adjusting, cut off their protruding ends and carefully sand them. To make this process easier, you can slightly cut the screws at the desired height before screwing them in. Then, at the final stage, you can simply break them off. After filling the screw holes with putty and waiting for them to dry, you should clean them with fine-grained sandpaper. Finally, all that remains is to paint the floor or lay the desired covering on it. Return to Contents</a>Floor repair using plywood sheets

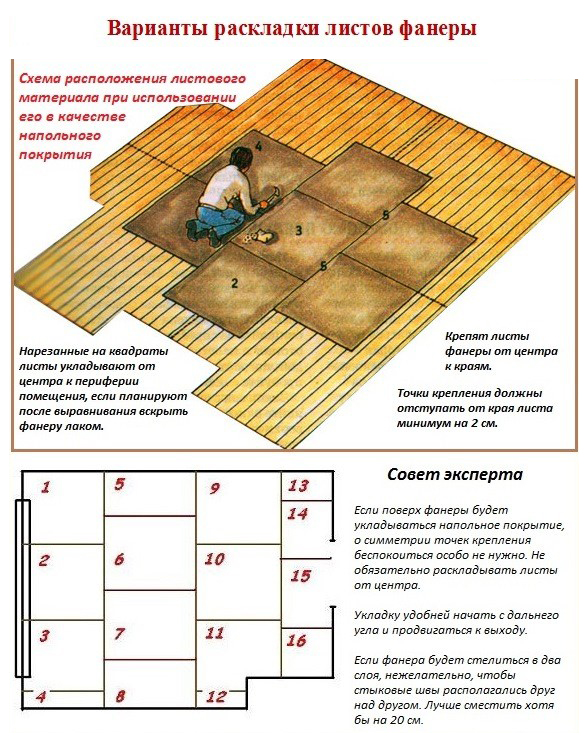

The process of eliminating creaking on a wooden floor.This method allows you to repair a creaking floor without disassembling it. It gives a good effect and does not require significant material costs. The first thing to do is to determine the distance from the upper floor level to the concrete floor. To do this, drill a small hole in the floorboard in one of the places where the sound is coming from. By inserting a strong wire into it, you can measure the distance to the concrete. The screws, the number of which should correspond to the number of creaking areas, should be longer than the measured distance. A screw is screwed into the drilled hole. This should be done carefully, especially near the concrete floor. The screw should create support, and not raise the floor. It is better if the screws reach the concrete, passing through the joists. The described operation is repeated in all those places where the creaking is heard. In order not to get hurt on the protruding sections of the screws, it is better to temporarily cover them with jars of suitable height. When all the screws are installed in their intended places, you should check if there are any more creaking areas of the floor. If necessary, loosen or tighten some screws. After checking and adjusting, cut off their protruding ends and carefully sand them. To make this process easier, you can slightly cut the screws at the desired height before screwing them in. Then, at the final stage, you can simply break them off. After filling the screw holes with putty and waiting for them to dry, you should clean them with fine-grained sandpaper. Finally, all that remains is to paint the floor or lay the desired covering on it. Return to Contents</a>Floor repair using plywood sheets Plywood floor repair diagram.In cases where the floors are not concrete but wooden, or tightening the floor with screws simply does not help, this method can help. It is also important that it will cost less than a complete replacement of the floor. It is especially effective when dried out floorboards bend and the floor surface takes on a wavy shape. Large-sheet plywood with a thickness of at least 15 mm is used. In addition, you will need several hundred screws. The sheets should be screwed to the floor as often as possible. The rule for laying plywood is simple:

Plywood floor repair diagram.In cases where the floors are not concrete but wooden, or tightening the floor with screws simply does not help, this method can help. It is also important that it will cost less than a complete replacement of the floor. It is especially effective when dried out floorboards bend and the floor surface takes on a wavy shape. Large-sheet plywood with a thickness of at least 15 mm is used. In addition, you will need several hundred screws. The sheets should be screwed to the floor as often as possible. The rule for laying plywood is simple:

A soft lining is placed under the plywood,similar to that placed under laminate. To sink the screw heads into the plywood, the holes for them in the upper part are countersunk. The seams and holes for the screws are filled and then cleaned. To level the floor under the tiles, the plywood can be replaced with a gypsum fiber sheet. An adhesive mixture is applied to the wood using a notched trowel, the sheet is laid on it and screwed in place with screws. After the mixture has dried, the first layer of gypsum fiber is coated with an adhesive mixture, on which the next sheet is laid and also screwed in place with screws through the first. The result is a leveled floor without any creaking. Return to contents</a>Other Ways to Stop Squeaking Floors Alternative and easier ways to stop squeaks are:

The described methods for eliminating creaking are the main ones, and everyone must decide for themselves which one to use.