A sofa is a piece of furniture that is alwaysis necessary in the interior. Furniture stores do not often offer those types of sofas or other products that would suit the interior design. It is possible that the owner himself has skills in making furniture, so he can afford to make his desire to make furniture for the house himself come true. The sofa is an integral part of the interior.And if the store offers high prices for this furniture, you can make it yourself. It should be foreseen that you will need various tools to create a sofa. Having prepared them, you can make a sofa according to your own dimensions and taste with your own efforts. The product will be made according to an individual drawing, which is associated with its uniqueness. Then resourcefulness, grip, skill and knowledge of carpentry can come to the rescue to create a unique masterpiece yourself. At the same time, you can know that the use of materials in the process of creating a sofa will not be associated with large cash expenses, as when buying it, taking into account the color of the upholstery to your own taste.

The sofa is an integral part of the interior.And if the store offers high prices for this furniture, you can make it yourself. It should be foreseen that you will need various tools to create a sofa. Having prepared them, you can make a sofa according to your own dimensions and taste with your own efforts. The product will be made according to an individual drawing, which is associated with its uniqueness. Then resourcefulness, grip, skill and knowledge of carpentry can come to the rescue to create a unique masterpiece yourself. At the same time, you can know that the use of materials in the process of creating a sofa will not be associated with large cash expenses, as when buying it, taking into account the color of the upholstery to your own taste.

Determining the design of the future product

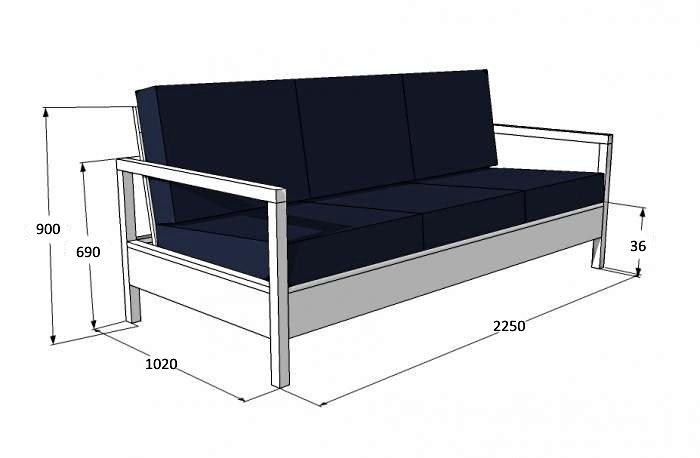

Overall dimensions of the sofa.Before starting work on creating a sofa, it is necessary to design its external appearance, and then develop a design for the furniture in the room as a whole. At the same time, you can come up with a design for a corner sofa that will match the main furniture. It should be borne in mind that it is difficult to make high-quality sofas at home. You can make a corner sofa yourself by making a frame mounted on stands or legs of the product. From time to time, a roller system mechanism is used. Due to the folding seats of the sofa, you can have special access to all its niches located on the sides. The niches will be mounted in the form of small boxes, and then installed on the sofa at your own discretion. It is necessary to plan the dimensions of the product carefully, because it may not fit in the prepared area of the room. All calculated dimensions are selected based on your own taste, preferences and the size of the room. At this stage, you should prepare a drawing in advance to create a regular or corner sofa.

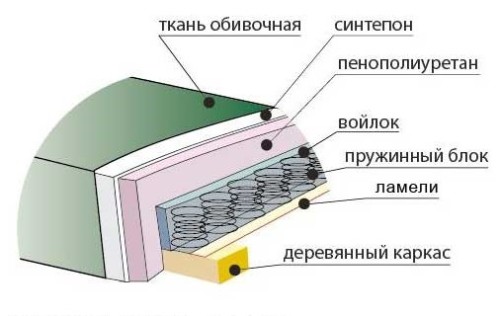

Overall dimensions of the sofa.Before starting work on creating a sofa, it is necessary to design its external appearance, and then develop a design for the furniture in the room as a whole. At the same time, you can come up with a design for a corner sofa that will match the main furniture. It should be borne in mind that it is difficult to make high-quality sofas at home. You can make a corner sofa yourself by making a frame mounted on stands or legs of the product. From time to time, a roller system mechanism is used. Due to the folding seats of the sofa, you can have special access to all its niches located on the sides. The niches will be mounted in the form of small boxes, and then installed on the sofa at your own discretion. It is necessary to plan the dimensions of the product carefully, because it may not fit in the prepared area of the room. All calculated dimensions are selected based on your own taste, preferences and the size of the room. At this stage, you should prepare a drawing in advance to create a regular or corner sofa. Sectional diagram of a soft sofa.Next, you should visit a building materials store. For beginners who are doing work related to the installation of a sofa for the first time, the most convenient solution would be to design a folding structure, not a corner one. The frame of the product should consist of a frame that has a rectangular shape, mounted on legs, taking into account all the appropriate dimensions. To create a frame, use beams, the best material for which is pine. Self-tapping screws are used to fasten the beam. Fastening should be done so that cracks do not occur. You can give the sofa frame maximum strength by screwing each beam in a cubic shape to the corners of the frame. Self-tapping screws are suitable for fastening. The bottom of the sofa will consist of plywood, the size of the sheet should correspond to the area of the frame. Plywood can be nailed with nails located at the same level. You can make a sofa based on the work in three stages, which includes:

Sectional diagram of a soft sofa.Next, you should visit a building materials store. For beginners who are doing work related to the installation of a sofa for the first time, the most convenient solution would be to design a folding structure, not a corner one. The frame of the product should consist of a frame that has a rectangular shape, mounted on legs, taking into account all the appropriate dimensions. To create a frame, use beams, the best material for which is pine. Self-tapping screws are used to fasten the beam. Fastening should be done so that cracks do not occur. You can give the sofa frame maximum strength by screwing each beam in a cubic shape to the corners of the frame. Self-tapping screws are suitable for fastening. The bottom of the sofa will consist of plywood, the size of the sheet should correspond to the area of the frame. Plywood can be nailed with nails located at the same level. You can make a sofa based on the work in three stages, which includes:

Let's look at each stage in more detail. Return to contents</a>

Step-by-step creation of a sofa

Return to Contents</a>Materials required for making the product Sofa frame diagram.You can make a sofa yourself without using special and additional types of material, pine beams and plywood are ideal here. First, the product must be designed in detail on paper. It is necessary to carefully consider any detail, for example, the level of the back of the product, a certain size of the height of its legs, the overall dimensions of the structure as a whole, etc. It is necessary to take into account that the entire load from the product will fall on the legs of the sofa and its back, the base must be strong. The back and seat should be provided with appropriate strength, the legs of the product must be firmly fixed to the frame. It is necessary to take into account when creating a sofa that the pine beam is prepared taking into account the appropriate size, which is 60x60 mm, and the thickness of the plywood sheets is taken equal to 12 mm. These types of materials are the most common, since they are associated with an affordable offer at an affordable price. Among all the fasteners, the following can be distinguished: self-tapping screws and steel corners. The necessary tools will be a screwdriver and a saw. better with foam rubber, tapestry or synthetic padding. The material is strengthened with covers that have a zipper. The frame can be made of beams, which differ from harder wood species, without having any additional disadvantages. All wooden elements must be covered with varnish, preserving the appearance of the wood. Return to the table of contents</a>Where to start assembling the sofa structure

Sofa frame diagram.You can make a sofa yourself without using special and additional types of material, pine beams and plywood are ideal here. First, the product must be designed in detail on paper. It is necessary to carefully consider any detail, for example, the level of the back of the product, a certain size of the height of its legs, the overall dimensions of the structure as a whole, etc. It is necessary to take into account that the entire load from the product will fall on the legs of the sofa and its back, the base must be strong. The back and seat should be provided with appropriate strength, the legs of the product must be firmly fixed to the frame. It is necessary to take into account when creating a sofa that the pine beam is prepared taking into account the appropriate size, which is 60x60 mm, and the thickness of the plywood sheets is taken equal to 12 mm. These types of materials are the most common, since they are associated with an affordable offer at an affordable price. Among all the fasteners, the following can be distinguished: self-tapping screws and steel corners. The necessary tools will be a screwdriver and a saw. better with foam rubber, tapestry or synthetic padding. The material is strengthened with covers that have a zipper. The frame can be made of beams, which differ from harder wood species, without having any additional disadvantages. All wooden elements must be covered with varnish, preserving the appearance of the wood. Return to the table of contents</a>Where to start assembling the sofa structure Scheme of sofa parts. Among the main elements of the sofa, we can highlight the presence of:

Scheme of sofa parts. Among the main elements of the sofa, we can highlight the presence of:

The production of a sofa can be divided into four stages.

Return to Contents</a>

Use of a beam and plywood for making a frame

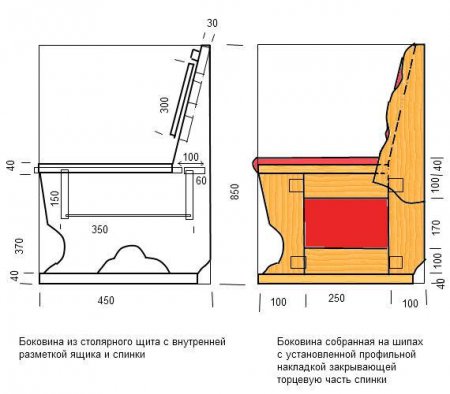

Scheme of the sofa side. You can prepare the whole set of tools yourself, you need to provide for the presence of:

Scheme of the sofa side. You can prepare the whole set of tools yourself, you need to provide for the presence of:

Without taking into account steel fasteners, glue is used,allowing each of the parts to be firmly and qualitatively connected to each other. This will make the structure stronger and safer. It is necessary to glue each joint using the appropriate glue. It should be ideally suited for the wooden product. Otherwise, it will be uncomfortable to rest and sit on the sofa you make. Sofa upholstery pattern.It will be necessary to assemble the sofa from timber by creating three frames measuring 72x1860 mm. The corner parts can be strengthened in the same way, and the installation principle is associated with a tenon on glue. The base of the sofa is made from two frames. The frames need to be connected to each other using four 60x60 mm bars about 200 mm long. You will need glued boards, which are laid in the part of the sofa where the mattress will be. It is imperative to strengthen the hinges to the frame, and the third frame should be covered with a board, like the side walls of the sofa. The back of the product should be fixed to the wall with 5-6 hinges, which will guarantee the product the required level, the bearing capacity of which is from 150 to 200 kg, the back should rest on both sides on the rack, if it is unfolded. When the manufacture of the sofa seat is already finished, they begin to create the frame of the back of the product. This can be done by following the appropriate steps, the same as when creating the seat of the product. If you need a folding sofa model, it is better to firmly fix the back of the product. This can be done using reliable steel corners of sufficient thickness. Experts do not recommend making the back strictly vertical. Return to contents</a>Carrying out finishing works independently

Sofa upholstery pattern.It will be necessary to assemble the sofa from timber by creating three frames measuring 72x1860 mm. The corner parts can be strengthened in the same way, and the installation principle is associated with a tenon on glue. The base of the sofa is made from two frames. The frames need to be connected to each other using four 60x60 mm bars about 200 mm long. You will need glued boards, which are laid in the part of the sofa where the mattress will be. It is imperative to strengthen the hinges to the frame, and the third frame should be covered with a board, like the side walls of the sofa. The back of the product should be fixed to the wall with 5-6 hinges, which will guarantee the product the required level, the bearing capacity of which is from 150 to 200 kg, the back should rest on both sides on the rack, if it is unfolded. When the manufacture of the sofa seat is already finished, they begin to create the frame of the back of the product. This can be done by following the appropriate steps, the same as when creating the seat of the product. If you need a folding sofa model, it is better to firmly fix the back of the product. This can be done using reliable steel corners of sufficient thickness. Experts do not recommend making the back strictly vertical. Return to contents</a>Carrying out finishing works independently For the working surface of the sofa you will needput the upholstery fabric and filler to make the sofa soft. Before covering the sofa with fabric, it is necessary to first grind down any of the sharp corners with sandpaper, since otherwise they can tear the fabric. Then proceed to creating a base from foam rubber. It is necessary to cover the base with tapestry. First, the foam rubber used must be wrapped in padding polyester, and then connect these materials using a zipper. After finishing, attach the foam rubber to the frame of the future product. First, the foam rubber is placed in a sewn tapestry cover. This function is performed by means of Velcro tape, one part of the tape should be attached to the product, and the other must be attached to the tapestry upholstery. It would be useful to remind about the upholstery of each edge, which will protrude slightly beyond all edges of the seat and back. The best way to hide the Velcro tape is to sew on a zipper, allowing you to remove the cover for washing. From time to time, foam rubber is attached to the product, which requires glue, but in this case the lining cannot be removed. Return to contents</a>Completion of final works RemainingSynthetic padding and foam rubber, as well as tapestry, are usually not thrown away, because these materials are also used to create exquisite sofa cushions. They are ideally combined with the product. Foam rubber can be attached to the back and seat. You can create a back in the form of separate different pillows of a small size. They are placed on the seat, hung using special Velcro on the back. One of the most convenient options may be the use of covers for pillows, the back of the sofa, its seat. This will help to predict the replacement of covers so that there is an opportunity to wash them, maintaining cleanliness. Upholstery fabric is covered with wrinkles over time, since it is used to cover soft elements of furniture. Therefore, the base should be wrapped with batting or synthetic padding. To complement the interior with a new sofa, you can sew beautiful curtains, install suitable lighting fixtures, sew special pillows to match the sofa. If you try, put in more effort and patience, you can create a coffee table, placing it next to the new sofa.

For the working surface of the sofa you will needput the upholstery fabric and filler to make the sofa soft. Before covering the sofa with fabric, it is necessary to first grind down any of the sharp corners with sandpaper, since otherwise they can tear the fabric. Then proceed to creating a base from foam rubber. It is necessary to cover the base with tapestry. First, the foam rubber used must be wrapped in padding polyester, and then connect these materials using a zipper. After finishing, attach the foam rubber to the frame of the future product. First, the foam rubber is placed in a sewn tapestry cover. This function is performed by means of Velcro tape, one part of the tape should be attached to the product, and the other must be attached to the tapestry upholstery. It would be useful to remind about the upholstery of each edge, which will protrude slightly beyond all edges of the seat and back. The best way to hide the Velcro tape is to sew on a zipper, allowing you to remove the cover for washing. From time to time, foam rubber is attached to the product, which requires glue, but in this case the lining cannot be removed. Return to contents</a>Completion of final works RemainingSynthetic padding and foam rubber, as well as tapestry, are usually not thrown away, because these materials are also used to create exquisite sofa cushions. They are ideally combined with the product. Foam rubber can be attached to the back and seat. You can create a back in the form of separate different pillows of a small size. They are placed on the seat, hung using special Velcro on the back. One of the most convenient options may be the use of covers for pillows, the back of the sofa, its seat. This will help to predict the replacement of covers so that there is an opportunity to wash them, maintaining cleanliness. Upholstery fabric is covered with wrinkles over time, since it is used to cover soft elements of furniture. Therefore, the base should be wrapped with batting or synthetic padding. To complement the interior with a new sofa, you can sew beautiful curtains, install suitable lighting fixtures, sew special pillows to match the sofa. If you try, put in more effort and patience, you can create a coffee table, placing it next to the new sofa.