Such flooring material as solid wood boards,is very popular today. It has a large number of positive aspects, starting with high strength and ending with a very presentable appearance. In terms of external design, it is similar to parquet board, but, unlike it, it is solid wood. When choosing a method for laying solid wood flooring, first of all, you need to think about whether it is worth it. It is worth it! With this design, the floor will last much longer, and its operation is practical. Solid wood boards are environmentally friendly,durable and long-lasting material. Such flooring is not afraid of aggressive factors, besides, it is easy to work with it by grinding, and the load on such material can be absolutely any. In order to independently carry out, you should first decide on the method. In addition, this process is carried out when the repair is almost finished. To make your work easier, it is recommended to study in more detail the features of such a board and how to choose it correctly.

Solid wood boards are environmentally friendly,durable and long-lasting material. Such flooring is not afraid of aggressive factors, besides, it is easy to work with it by grinding, and the load on such material can be absolutely any. In order to independently carry out, you should first decide on the method. In addition, this process is carried out when the repair is almost finished. To make your work easier, it is recommended to study in more detail the features of such a board and how to choose it correctly.

Choosing the right board

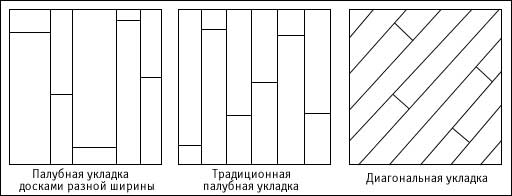

To ensure that the floor serves properly, it shouldpay special attention to the finishing material. Its quality directly affects how much the result will satisfy its owner. Therefore, there are points that it is advisable to pay more attention to when buying solid wood boards: Types of solid wood flooring installation.

Types of solid wood flooring installation.

By following these recommendations, you can choose a truly high-quality product, and not some kind of consumer goods. Return to contents</a>

Basic styling methods

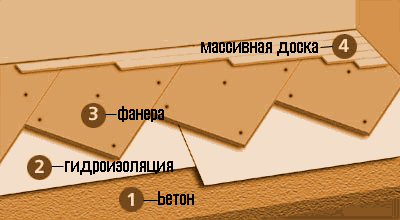

Scheme of laying solid wood boards on a plywood floor.When laying solid wood flooring, the base should be thoroughly prepared. The choice of method of work will depend on this. Boards can be laid on several types of base:

Scheme of laying solid wood boards on a plywood floor.When laying solid wood flooring, the base should be thoroughly prepared. The choice of method of work will depend on this. Boards can be laid on several types of base:

- cement-concrete or simply concrete screed;

- plywood;

- natural wood;

- lags;

- staples.

The first option is used most often, that is,coupler. In order to carry out the installation, glue is used that has a high index regarding temperature differences, but at the same time is absolutely non-toxic to humans. When laying solid wood boards on a cement-concrete or concrete screed, you should check it for strength and see if there is any damage in the form of irregularities, cracks or chips. It is best if such a surface has 6-7% humidity, otherwise you will have to take care of waterproofing. As for plywood, this method is also often used. But there is a nuance here. To lay solid wood boards on plywood, you should remember about the vapor barrier layer. The moisture level of the material should not exceed 10%, and two-component glue is used for the installation itself. To secure the edges, you will need a pneumatic gun with 30-centimeter studs. Scheme of laying solid wood boards on a wooden floor.The convenience of the method of laying on logs lies in the speed of installation work. There is no need to worry about cement mortars. A waterproofing material is laid under the logs, which is preferably based on a film of polyethylene or penofol. A few words about the staples. Builders call this method "floating". Using it, it is possible to save 30-40% on installation work. The technology of laying aluminum products involves installation together with silicone compensators, which provide improved fastening of the edges. It also happens that solid boards are laid over an old wooden covering. But in this case, you should be sure that it has still retained its reliability and strength, and the moisture level of the material is 8-10%. If the old base has a varnished coating, then it must be removed, after which the surface is carefully sanded. This is done in order to eliminate any irregularities. It should also be noted that when installing solid boards, the same direction as the previous coating should be observed. To secure them, you should stock up on self-tapping screws with an anti-corrosion coating. Having familiarized yourself with each method, you can, having weighed all the pros and cons, choose the one that is most convenient in a particular case. Return to the table of contents</a>

Scheme of laying solid wood boards on a wooden floor.The convenience of the method of laying on logs lies in the speed of installation work. There is no need to worry about cement mortars. A waterproofing material is laid under the logs, which is preferably based on a film of polyethylene or penofol. A few words about the staples. Builders call this method "floating". Using it, it is possible to save 30-40% on installation work. The technology of laying aluminum products involves installation together with silicone compensators, which provide improved fastening of the edges. It also happens that solid boards are laid over an old wooden covering. But in this case, you should be sure that it has still retained its reliability and strength, and the moisture level of the material is 8-10%. If the old base has a varnished coating, then it must be removed, after which the surface is carefully sanded. This is done in order to eliminate any irregularities. It should also be noted that when installing solid boards, the same direction as the previous coating should be observed. To secure them, you should stock up on self-tapping screws with an anti-corrosion coating. Having familiarized yourself with each method, you can, having weighed all the pros and cons, choose the one that is most convenient in a particular case. Return to the table of contents</a>

Preparatory stage of installation

In addition to the fact that the workspace must be prepared, you should also stock up on the necessary tools: The rows between the solid boards are fastened using staples or glue placed in the groove.

The rows between the solid boards are fastened using staples or glue placed in the groove.

- a metal ruler;

- with a simple pencil;

- spatula;

- joiner's corner;

- pneumatic stapler;

- screwdriver and drill;

- wooden kiyankoy;

- screws.

Regarding fasteners, there is the followingrecommendation: it is better to take self-tapping screws that have an anti-corrosion galvanic coating. This type of elements does not rust, in addition, they have the property of smoothing out the impact of seasonal influences. Some believe that you can use nails that are specially designed for parquet, but this is not true. Stainless steel staples are used on the bottom side. They are used to fix two elements by snapping them into grooves or fastening them with screwed-in self-tapping screws. As noted above, if the method of laying on a screed is chosen, then in no case should they come into contact with each other. An intermediate layer should be created, for which a primer mastic and a vapor barrier film are used. All cracks that form in the joints are glued. Experts recommend that, before starting to lay, the solid board lies in the workroom for a week. And so that it is well "ventilated", it is better to lay the lamellas on stands. Return to the table of contents</a>

How to lay a massive board on a plywood or wooden base?

When purchasing plywood, it is advisable to select sheets that are 13-15 mm thick. The entire installation process is carried out in the following steps:

If the "floating" installation method is selectedsolid wood boards, then you should make sure that the base and the boards themselves are separated from each other. For this method, the fastening of the elements occurs using solid wood planks. "Floating" installation is perfect in cases where you plan to make a warm floor system, since in this case, compensation for temperature and humidity differences is ensured. The use of self-tapping screws implies their fastening at a distance of 25-30 cm from each other. And in order to avoid splitting the material, holes are made on the side where the spike is located. The cap should not "look out" above the surface, so that later it would be possible to carefully close it with rivets. Solid wood boards are fastened to a wooden flooring in a similar way. But if the reliability of the base is in doubt, then it is better to refuse this. The old coating should be dismantled and a new one should be started, which is not always rational and economical. Laying solid wood boards is similar to laminate. Therefore, doing it yourself will not be particularly difficult. It is recommended to start laying from the far corners, so that you can evaluate the result of your efforts. After all, it may turn out that the array will not “obey” the owner, and then you will have to turn to professionals for help.