Construction work requires a special approach.Each owner has his own preferences regarding how this or that structure will look. Among the most popular finishing materials, special attention should be paid to plasterboard. It has been used in construction for more than 100 years, but even today, plasterboard is an indispensable part of any repair. Therefore, many people have a question about how to do it themselves. The thing is that laying plasterboard on a wall, ceiling, etc. is very simple. However, if you plan to do all the work yourself, you need to take into account some subtleties. Today, plasterboard is actively used for leveling walls inside buildings.

Today, plasterboard is actively used for leveling walls inside buildings.

Preparation for laying on the surface of the plasterboard wall

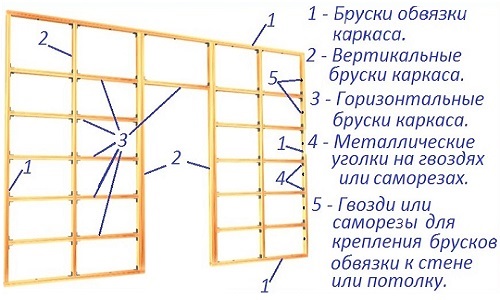

At this stage, you need to do the following:actions: prepare materials and a set of tools that will be needed during the work; allow free passage to structures that need finishing; prepare the wall surfaces themselves. What you need to know when purchasing materials. Construction of a wooden frame for plasterboard

Construction of a wooden frame for plasterboard

Return to Contents</a>

Preparation of the instrument

Before you start laying drywall yourself, you need to prepare the tools for the job. As a rule, it is recommended to use the following devices: Tool for working with plasterboard.

Tool for working with plasterboard.

- screwdriver or electric drill with a bit for self-tapping screws;

- a hammer;

- perforator;

- mounting knife;

- scissors for metal.

When preparing the primary wall planesIt is necessary to have free access to the object in order to clean all easily peeling materials from the wall plane and to correct deformed surfaces. Return to contents</a>

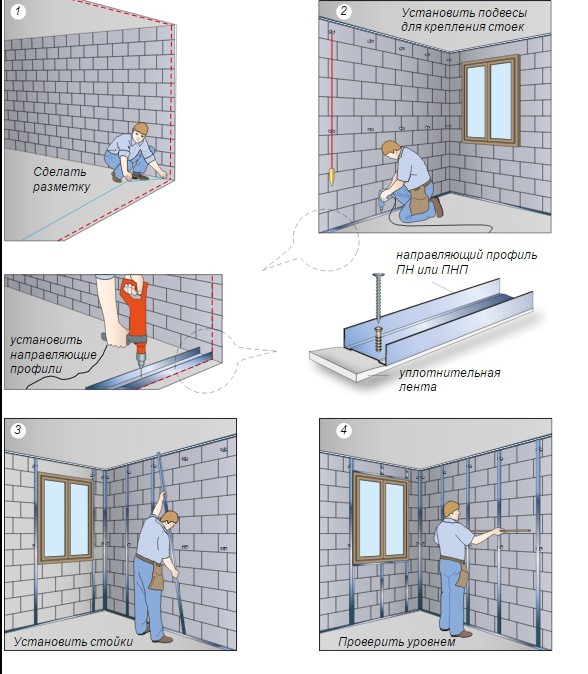

Marking in the room

Before you start laying drywall, domarking the places of installation of finishing materials. At the same time, it is necessary to treat this action with the utmost responsibility in order to simplify the process of laying drywall and reduce the amount of GKL consumed. The marking is done in the following gradation: Stages of installing a frame for plasterboard on a wall

Stages of installing a frame for plasterboard on a wall

In order to lay drywall on the wall surface with the greatest efficiency, when marking, you should adhere to the following tips:

Return to Contents</a>

Construction of a support frame for mounting drywall

Types of profiles for installing plasterboard.Profile guides are mounted to the ceiling and floor planes along the pre-marked marking lines, for which, as a rule, a hammer drill is used. The appropriate holes are drilled in the floor and ceiling planes and dowel nails are installed there. And the profiles are attached to them using screws. It is important to take into account that the strength of the entire structure depends on the accuracy of this operation. Therefore, the distance between the fastening elements for fixing the profile guides is taken in the range from 40 cm to 60 cm (depending on the estimated load on the planes of the walls of the plasterboard sheets). At the next stage, the profile guides are mounted to the wall planes in the same way, measuring them between the lower and upper systems of the profile guides. In other words, the process must be performed in such a way that all the profile guides are located in the same plane.

Types of profiles for installing plasterboard.Profile guides are mounted to the ceiling and floor planes along the pre-marked marking lines, for which, as a rule, a hammer drill is used. The appropriate holes are drilled in the floor and ceiling planes and dowel nails are installed there. And the profiles are attached to them using screws. It is important to take into account that the strength of the entire structure depends on the accuracy of this operation. Therefore, the distance between the fastening elements for fixing the profile guides is taken in the range from 40 cm to 60 cm (depending on the estimated load on the planes of the walls of the plasterboard sheets). At the next stage, the profile guides are mounted to the wall planes in the same way, measuring them between the lower and upper systems of the profile guides. In other words, the process must be performed in such a way that all the profile guides are located in the same plane. Scheme of cutting drywall using a knife.The next step, using perpendicular markings to the floor, is to attach hangers to the wall surfaces for installation, which will subsequently fix the profile posts, giving extra rigidity to the entire structure. Their installation is also done using dowel nails, but it will be important to follow the advice:

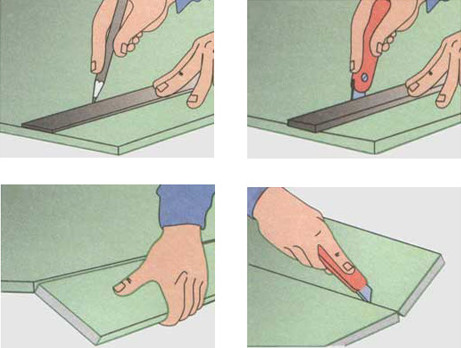

Scheme of cutting drywall using a knife.The next step, using perpendicular markings to the floor, is to attach hangers to the wall surfaces for installation, which will subsequently fix the profile posts, giving extra rigidity to the entire structure. Their installation is also done using dowel nails, but it will be important to follow the advice:

After this, the profile posts are attached toframe. To do this, they are threaded into the cavities of the lower and upper profile guides and screwed at the connection points using self-tapping screws not only to the guide profiles, but also to the rectilinear hangers, and the ends that come out are bent towards the inside of the frame. When performing this action, it may be necessary to increase or cut the profile racks, since their length must coincide with the wall surfaces. Thus, the racks can be increased using special connectors and self-tapping screws, while the excess parts can be cut off using ordinary metal cutting scissors. All surfaces requiring finishing should be equipped in a similar way. It should be taken into account that in order to increase the strength and improve the installation of drywall sheets, it is recommended to install profiles perpendicular to the longitudinal sheets, attaching them to them using fasteners. Return to contents</a>

Final installation of drywall sheets on the wall plane

Before starting to level the wall surfaceIt is recommended to solve the issue of thermal insulation of the room and penetration of extraneous noise into it with plasterboard sheets. This should be done even before the planes of the walls are covered with plasterboard sheets. As an example, such materials can be foam plastic, cork, isover, glass wool, which fill the voids in the cavity of the supporting structure. In addition, at the previous step, it is necessary to install all communications and engineering systems. Plasterboard sheets should be mounted to the frame using self-tapping screws for metal, maintaining a distance between them of 0.3 - 0.4 m. In this case, plasterboard sheets should be attached to all rigidly fastened parts of the supporting frame. Mounting plasterboard sheets on the wall surface should be carried out subject to certain requirements listed below:

Cutting of the plasterboard sheet must be carried outusing a mounting knife or a special cutter. After all the manipulations have been carried out, when the walls are laid with plasterboard sheets, they move on to the stage of finishing work (puttying, painting, pasting, etc.).