Practical, long-lasting and satisfyingeven the most demanding consumers, the building material called laminate is currently considered the most popular floor covering. This material has many advantages, but the most important is that laying laminate flooring with your own hands is a very simple process and is accessible to almost anyone who knows how to handle construction tools at least a little. Laminate is very reliable, durable and capablesatisfy the tastes of even the most demanding customers finishing material. It does not matter whether you are familiar with it or not, what is important in such a matter is the desire to arrange your own home. You can always ask friends and acquaintances who have already encountered such a process as laying laminate with their own hands, without involving specialists. In extreme cases, you can master laying laminate by trial and error.

Laminate is very reliable, durable and capablesatisfy the tastes of even the most demanding customers finishing material. It does not matter whether you are familiar with it or not, what is important in such a matter is the desire to arrange your own home. You can always ask friends and acquaintances who have already encountered such a process as laying laminate with their own hands, without involving specialists. In extreme cases, you can master laying laminate by trial and error.

Preparatory work

Laminate is a multilayer material.Its standard thickness is from 6 to 12 mm, length - from 1 to 1.5 m, and width - 20 cm. This material is produced in the form of small tiles measuring 1200x400 mm or 400x400 mm. It is also good because it is made in various colors and shades, thanks to which it is possible to choose the most suitable option individually for the interior of any room. Laminate design diagram.Laying laminate flooring yourself initially involves choosing and purchasing the material, as well as carrying out preparatory work. Laminate is considered a demanding material, since the surface for its installation must be perfectly flat and smooth. The following building coverings can be used as a base for such material:

Laminate design diagram.Laying laminate flooring yourself initially involves choosing and purchasing the material, as well as carrying out preparatory work. Laminate is considered a demanding material, since the surface for its installation must be perfectly flat and smooth. The following building coverings can be used as a base for such material:

- concrete;

- linoleum;

- tile;

- tree.

Let's consider the preparation of each of the listedcoatings, which will help determine the most suitable option. Preparatory work with a concrete base means preliminary removal of the old coating, checking for unevenness and cracks, as well as screeding with a cement-sand mixture, which after pouring will require about 25 days to dry completely. Only after this can you safely begin laying the final floor covering. In this case, you should remember about the mandatory vapor barrier layer. Tools for laying laminate flooring.Laying laminate on an existing wooden floor is only allowed if the base is not affected by pests or fungus. If there are minor irregularities and differences, they must be removed by regular sanding. In case of serious damage, it is better to replace the wooden base. Laying laminate on an uneven concrete and wooden base is also carried out with preliminary leveling of the surface using sheets of chipboard or plywood. Since any firmly fixed, moisture-resistant and even surfaces can serve as a base for laying laminate, linoleum and tiles are quite suitable for this role. If the base is correctly laid on the screed, the floor will be quite even, so there will be no need to dismantle the base. At the same time, such a base does not require vapor barrier, it will be enough to lay the underlay. Return to the table of contents</a>

Tools for laying laminate flooring.Laying laminate on an existing wooden floor is only allowed if the base is not affected by pests or fungus. If there are minor irregularities and differences, they must be removed by regular sanding. In case of serious damage, it is better to replace the wooden base. Laying laminate on an uneven concrete and wooden base is also carried out with preliminary leveling of the surface using sheets of chipboard or plywood. Since any firmly fixed, moisture-resistant and even surfaces can serve as a base for laying laminate, linoleum and tiles are quite suitable for this role. If the base is correctly laid on the screed, the floor will be quite even, so there will be no need to dismantle the base. At the same time, such a base does not require vapor barrier, it will be enough to lay the underlay. Return to the table of contents</a>

What is necessary for styling?

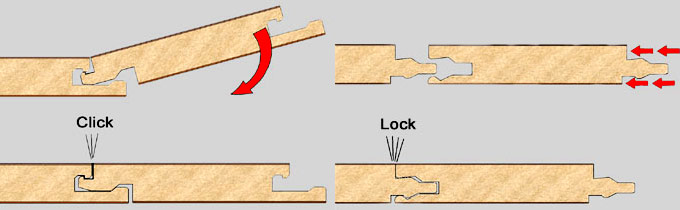

The technology of laying is not actuallydifficult and impossible, the main thing is to approach the work responsibly and follow the recommendations described. Before starting the process, it is necessary to bring the material in the factory packaging into a room with a temperature of at least +18 degrees, and humidity of at least 70%. In such conditions, the laminate should lie for 48 hours so that it has time to get used to it. Scheme of laying laminate with different types of locks. Laying laminate without the necessary tool is simply impossible. Therefore, it is worth preparing the following list of tools in advance:

Scheme of laying laminate with different types of locks. Laying laminate without the necessary tool is simply impossible. Therefore, it is worth preparing the following list of tools in advance:

- Ruler and pencil;

- a hammer;

- clamp;

- a jigsaw;

- grandmother (bar for podbivaniya);

- spacer wedges;

- parobarrier (polyethylene film) when laid on a concrete base;

- substrate.

As mentioned earlier, it impliesuse only a flat and solid surface as a base. Therefore, it would be useful to once again make sure that the base has these qualities. Most experts recommend using a surface with a difference of no more than 2 mm per 20 sq. m of floor base area. The difference left during the work will be smoothed out by the underlay. Return to contents</a>

Installation of floor covering

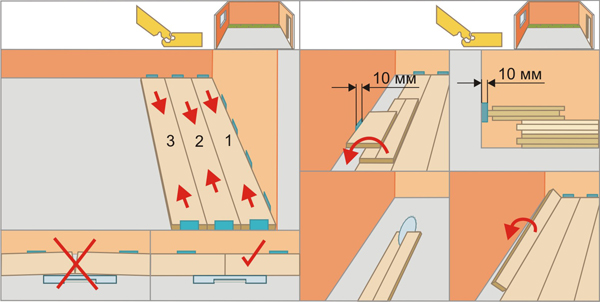

Laminate flooring installation technology.The instructions for installing laminate flooring are quite simple. If you do the installation yourself, it is better to lay the material perpendicular to the wall where the window is located, which will allow you to hide the joints between the panels in the flow of light. The film is laid over the entire area of the room, if it is not enough, you can lay another roll next to it, and the joints of the film should be glued with tape. Only a completely dry base should be covered with polyethylene film, which will act as a vapor barrier material. After this, you should lay the underlay, preferably cork, if you are concerned about the environmental friendliness of the materials used. It is important to lay the first row correctly at the beginning of laying the laminate. Beforehand, you should install spacer plastic wedges over the entire area of the room at the level of the future floor covering. This is required in order to provide a small gap between the walls and the laminate, because the coating used tends to expand / contract with an increase / decrease in temperature.

Laminate flooring installation technology.The instructions for installing laminate flooring are quite simple. If you do the installation yourself, it is better to lay the material perpendicular to the wall where the window is located, which will allow you to hide the joints between the panels in the flow of light. The film is laid over the entire area of the room, if it is not enough, you can lay another roll next to it, and the joints of the film should be glued with tape. Only a completely dry base should be covered with polyethylene film, which will act as a vapor barrier material. After this, you should lay the underlay, preferably cork, if you are concerned about the environmental friendliness of the materials used. It is important to lay the first row correctly at the beginning of laying the laminate. Beforehand, you should install spacer plastic wedges over the entire area of the room at the level of the future floor covering. This is required in order to provide a small gap between the walls and the laminate, because the coating used tends to expand / contract with an increase / decrease in temperature. Photo 1. Sequence of laminate flooring installation.Lay the first panel in the corner of the room. Then mark one panel exactly in half and cut it with a jigsaw. Fix one half next to the first in the corner, which will mark the second row of laminate flooring for you. This is called a mixed installation method - staggered placement of panels. Since the laminate is assembled using a floating method, staggered installation will allow the load to be evenly distributed around the perimeter. Now you should lay one panel in each row. Lay the 2nd panel of the 1st row next to the 1st panel, then place a babyshka at the end and hit it with a rubber hammer. This is the technology for laying laminate panels. When installing the laminate in a connecting lock, the panels should be connected at an angle of approximately 20 degrees. The panels are inserted into the lock and lowered, after which you should hear a light click - this is a sign (Photo 1). The last panel of any row should be laid in the previous row. The same technology of laying laminate flooring with your own hands applies as before. To place a block in the gap between the panels and the wall, you should use a clamp, one end of which should be inserted into the end of the panel, and the other should be lightly tapped with a hammer. Return to contents</a>

Photo 1. Sequence of laminate flooring installation.Lay the first panel in the corner of the room. Then mark one panel exactly in half and cut it with a jigsaw. Fix one half next to the first in the corner, which will mark the second row of laminate flooring for you. This is called a mixed installation method - staggered placement of panels. Since the laminate is assembled using a floating method, staggered installation will allow the load to be evenly distributed around the perimeter. Now you should lay one panel in each row. Lay the 2nd panel of the 1st row next to the 1st panel, then place a babyshka at the end and hit it with a rubber hammer. This is the technology for laying laminate panels. When installing the laminate in a connecting lock, the panels should be connected at an angle of approximately 20 degrees. The panels are inserted into the lock and lowered, after which you should hear a light click - this is a sign (Photo 1). The last panel of any row should be laid in the previous row. The same technology of laying laminate flooring with your own hands applies as before. To place a block in the gap between the panels and the wall, you should use a clamp, one end of which should be inserted into the end of the panel, and the other should be lightly tapped with a hammer. Return to contents</a>

Proper care for a new floor covering

Laying laminate flooring yourself will allow you not tonot only to save money on the services of specialists, but also, first of all, to create a beautiful and cozy interior of your premises. However, in order for your efforts not to be in vain, you need to treat the new floor covering with care. Recommendations for its use are quite simple: regularly carry out wet cleaning and do not allow the laminate to come into contact with liquid for a long time. Due to the ease of installation and simple maintenance, laminate continues its triumphant march through the windows of construction stores, offices, as well as people's homes and apartments.</ ul>