Silk-screen wallpaper is commontrend in the interior of modern apartments. They are chosen both for living rooms and for passage rooms (hallways and front rooms). Silk-screen printing is classified as vinyl wallpaper and is placed at one of the highest levels in terms of quality properties and variety of patterns. A distinctive feature of their appearance is the iridescent silky gloss on the surface, imitating silk fabric or its patterns. Silk-screen printed wallpaper is one of the mostquality materials for wall decoration. Pasting silk-screen wallpaper is not particularly difficult. But it is worth considering some nuances of the manufacturer in order to perform the pasting work qualitatively and without mistakes. Because it will be impossible to redo an incorrectly pasted canvas.

Silk-screen printed wallpaper is one of the mostquality materials for wall decoration. Pasting silk-screen wallpaper is not particularly difficult. But it is worth considering some nuances of the manufacturer in order to perform the pasting work qualitatively and without mistakes. Because it will be impossible to redo an incorrectly pasted canvas.

Sign of quality silk on the walls

Silk-screen wallpaper is known for its high price.compared to other types of wallpaper. This is explained by the fact that they are produced using an expensive method of applying a pattern by hot stamping on paper. It is the pressed vinyl on the top layer of wallpaper that creates the effect of applied silk. However, some manufacturers save on production processes and apply the top coating in a crude and artisanal manner, due to which the latter loses its elasticity. Such low-quality products will not be well moistened when pasted on walls. If you glue wallpaper with poorly made vinyl silk-screen printing, then when applying glue, their edges will turn out, preventing good adhesion to the walls. The order of gluing wallpaper on a vertical surfacesurface. If you glue silk-screen printing with a high-quality top layer, then both it and the paper base of the wallpaper will equally well demonstrate their adhesive properties. As mentioned above, silk-screen wallpaper is classified as vinyl, which is based on vinyl paper. During the production process, it is painted, heated and goes through the embossing stage. Due to this, the wallpaper paper at the output is the thinnest, but very durable. Nevertheless, even thin silk vinyl wallpaper is produced with different vinyl thicknesses. Return to contents</a>

The order of gluing wallpaper on a vertical surfacesurface. If you glue silk-screen printing with a high-quality top layer, then both it and the paper base of the wallpaper will equally well demonstrate their adhesive properties. As mentioned above, silk-screen wallpaper is classified as vinyl, which is based on vinyl paper. During the production process, it is painted, heated and goes through the embossing stage. Due to this, the wallpaper paper at the output is the thinnest, but very durable. Nevertheless, even thin silk vinyl wallpaper is produced with different vinyl thicknesses. Return to contents</a>

Properties and advantages of screen printing

Despite its high price, silk vinylfully justifies it. Thanks to the qualities of vinyl, you can not only professionally decorate your home, but also enjoy working with it. It is not for nothing that people believe that if you need to check a person, you can glue wallpaper together with him. So, silk-screen printing has the following properties:

- absence of odor and hazardous substances and impurities;

- has a long service life (up to 15 years);

- it is easy to wash, wet and dry cleaning, preserving the original appearance;

- resistant to light, so it does not burn out in the sun;

- has a huge number of different variations of patterns, ornaments and patterns;

- It is easily combined in an interior with other kinds of paper wall-papers and various drawings if it is demanded by a design idea.

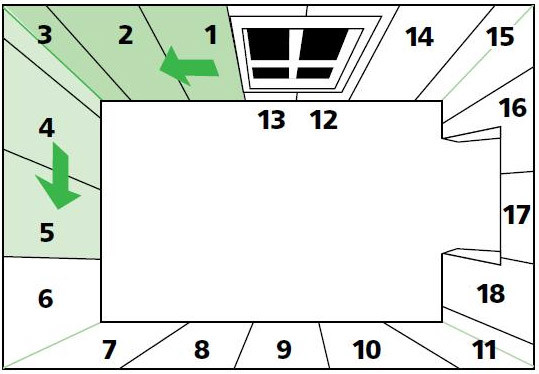

Wallpapering scheme around switches andsockets. If you have a question about how to properly glue wallpaper, then know that the next stage of the process is working with silk-screen printing. Professionals advise starting to glue the walls from the window opening on the left and then along the entire perimeter of the room. This also applies to silk-screen printing. Thus, the seams and joints of the wallpaper sheets will not stand out in the sunlight pouring from the window. Due to this, the pasted room looks neat, creating the effect of printed material on the walls. Return to the table of contents</a>

Wallpapering scheme around switches andsockets. If you have a question about how to properly glue wallpaper, then know that the next stage of the process is working with silk-screen printing. Professionals advise starting to glue the walls from the window opening on the left and then along the entire perimeter of the room. This also applies to silk-screen printing. Thus, the seams and joints of the wallpaper sheets will not stand out in the sunlight pouring from the window. Due to this, the pasted room looks neat, creating the effect of printed material on the walls. Return to the table of contents</a>

Preparing walls for gluing

Silk vinyl is glued exclusively to flat surfaceswalls. If we are talking about previously aligned wall blocks, then you can start gluing silk-screen wallpaper without preliminary preparation of the walls. However, if they require elaboration, then the following inventory will be needed:

- putty for walls (starting and ending);

- spatulas;

- sandpaper;

- primer.

The wall is completely freed from old wallpaper,dirt, mold and dust. All surface irregularities are worked out with a starting putty. Using a spatula, all the flaws of the walls are leveled out with neat strokes in a 3 mm layer. The result is fixed with a final putty, which is applied in the same way as the starting one. The sealed walls dry for 24 hours and then are sanded with sandpaper. The primer layer is applied at the end of the sanding process. Such manipulations will improve the adhesion of silk-screen printing to the walls. It is very important to work out all the irregularities on the surface of the walls, since unfilled areas will stand out strongly through the pasted wallpaper. Return to the table of contents</a>

How to glue silkscreen printing?

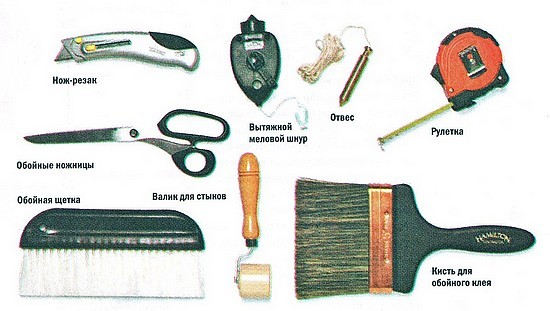

Tools for gluing silk-screened wallpaper.In the room where the gluing process will take place, all windows are tightly closed. In any case, it is necessary to ensure that there are no drafts: they are destructive for newly pasted wallpaper. The following materials are required for this process:

Tools for gluing silk-screened wallpaper.In the room where the gluing process will take place, all windows are tightly closed. In any case, it is necessary to ensure that there are no drafts: they are destructive for newly pasted wallpaper. The following materials are required for this process:

- special wallpaper glue for silk vinyl;

- roulette or ruler;

- brush;

- scissors;

- a simple pencil;

- rubber roller;

- dry and clean cloth.

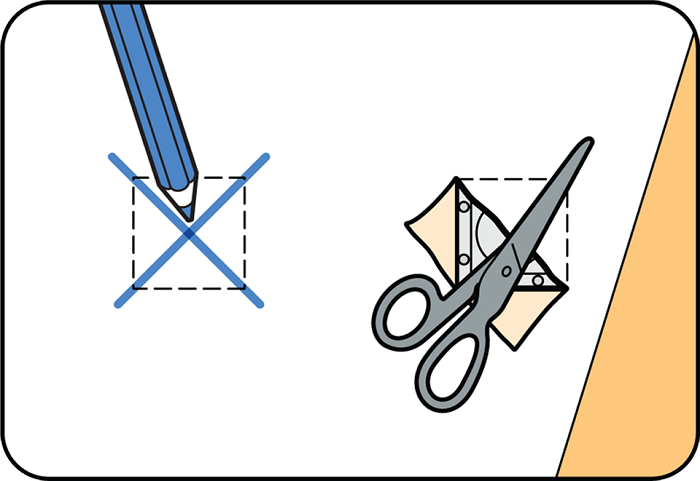

A roll of wallpaper is rolled out on a flat surface.The required length of the wallpaper sheet is measured with a tape measure and cut off. Glue prepared according to the instructions on the package is applied to its back side with a brush. The glue should be applied evenly to the surface of the wallpaper and then left to soak for 10 minutes. During this time, it is recommended to apply one layer of glue to the entire required section of the wall with the same brush, concentrating it on the upper and lower borders of the walls. Silk-screen printing is applied to the upper border of the wall and slowly but firmly pressed over the entire gluing area. Smooth out the glued sheet of silk vinyl with a rubber roller, starting from the middle and smoothly moving towards the corners, trying not to damage the wallpaper and eliminating any bubbles and folds that have arisen. Pasting the corners of the room is done as follows. The wallpaper sheet is positioned so that one part of it occupies one section of the wall, and the other - the opposite section. The next sheet of silk-screen printing is selected according to the pattern of the previous corner sheet, so that the pattern matches at the joint of the wallpaper sheets. All the rolls of silk-screen printing are glued in this way. It is necessary to join the wallpaper sheets very carefully and tightly to each other, so as not to allow the occurrence of sloppy joints. This can spoil the entire appearance of the walls. In order not to stain the finished wallpaper on the walls, hands should be periodically washed under running water during work and wiped dry with a clean cloth or towel.