Experts do not recommend laying linoleumdirectly onto the concrete floor, since such a foundation is not even. To smooth out or wipe the concrete surface of the floor is not enough, because it will not be ideal. Before putting linoleum on the concrete floor, a complex of various activities is held.  Structure of household linoleum. Each type of linoleum, which is planned to cover the concrete surface of the floor, affects the way it is prepared for the flooring of the flooring. All work should be carried out taking into account certain requirements for this or that kind of premises. The concrete surface of the floor increases the service life of the linoleum coating, and there are no problems with its laying.

Structure of household linoleum. Each type of linoleum, which is planned to cover the concrete surface of the floor, affects the way it is prepared for the flooring of the flooring. All work should be carried out taking into account certain requirements for this or that kind of premises. The concrete surface of the floor increases the service life of the linoleum coating, and there are no problems with its laying.

How to prepare a concrete surface and a linoleum coating?

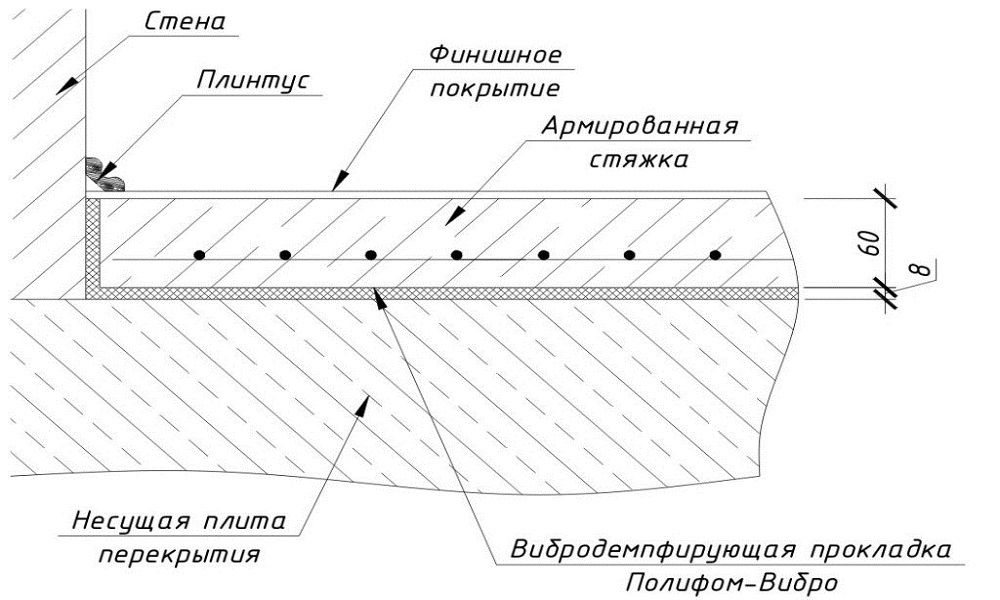

Back to contents</a> Getting a good quality floor screedIdeal floor covering preparation of its surface and laying of linoleum are made with strict observance of technology. If the floor of concrete is prepared correctly, this is the key to the aesthetic appearance of the room. Any defects can lead to various deformations, as well as ruptures of linoleum. To this end, carefully level the concrete screed, which will eliminate all chipped and cavities. For leveling the outdated screed using special leveling solutions. In this case, you can successfully combine the floor leveling with its repair.  Tools for floor screed. To get a quality screed, you do not need too much time and special professional skills with special knowledge. The following types of tools and materials will be needed:

Tools for floor screed. To get a quality screed, you do not need too much time and special professional skills with special knowledge. The following types of tools and materials will be needed:

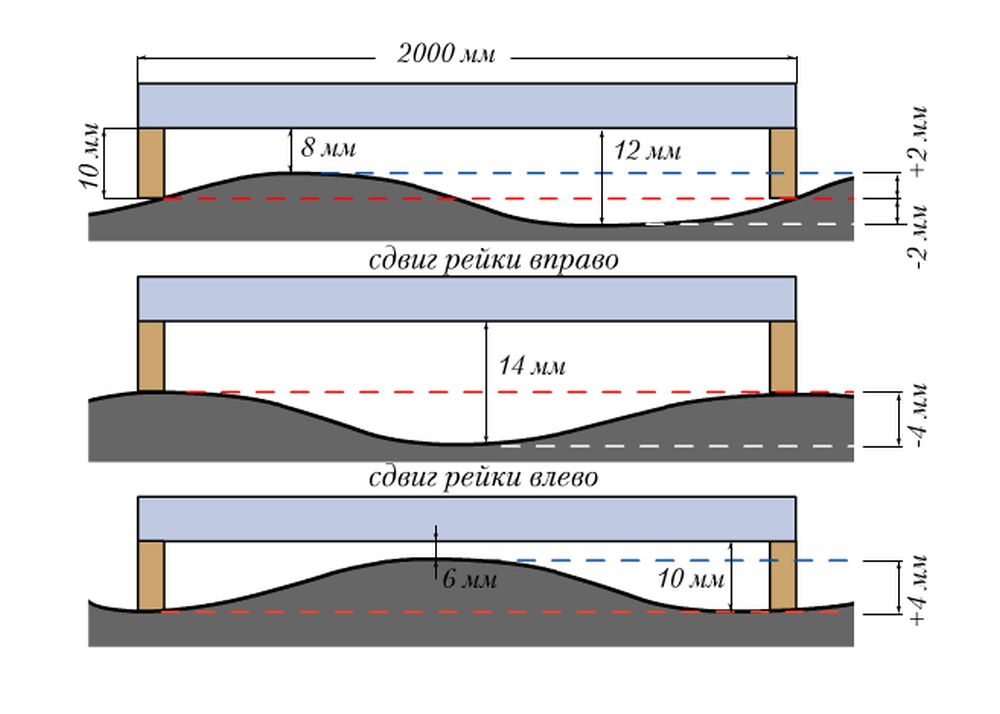

Before starting the application of cement-sand mixture during the screeding process, the composition is tested for resistance to cracking. Back to contents</a> How to make all measurements? Cement-sand mixture is applied only on the marked surface of the floor. In order for the floor level to be correctly set, the starting point on the horizontal floor surface is determined. However, this stage can cause difficulty for a beginner master. Usually, the emphasis is on the walls, which are located one opposite the other. After measuring the distance equal to 1 cm from the floor surface using a building level, a straight line is drawn. On the opposite wall, mark the line, making the same measurements. Obtain an even plane between the lines drawn.  Floor Screed Scheme. To check the smoothness of the floor surface use a long bar. When measuring a room, you should measure not four but four sides. This is due to the fact that the opposite walls have different lengths. Using a level of two meters, check the curvature and the horizontal level of the floor. With the existing floor height differences of more than 15-20 mm, work is necessarily carried out to create an equalizing screed. Before the beginning of the work, the light beams from the metal are installed in accordance with the level. The distance should be less than the length of the rule by 15-20 cm. The choice of its length will depend on the number of people who carry out all the work, since one person is not able to cope with a tool whose length is more than 1 m. using a quick-setting adhesive on a gypsum base. The glue should be applied in the form of "lozenges", located every 25-30 cm along the slats. To achieve horizontality for each plane in which the slats should be located, you can use the level. If the glue on the gypsum base is already seized, then the cement and sand solution (1: 3) is poured onto the floor, filling the space on the plane between the beacons.

Floor Screed Scheme. To check the smoothness of the floor surface use a long bar. When measuring a room, you should measure not four but four sides. This is due to the fact that the opposite walls have different lengths. Using a level of two meters, check the curvature and the horizontal level of the floor. With the existing floor height differences of more than 15-20 mm, work is necessarily carried out to create an equalizing screed. Before the beginning of the work, the light beams from the metal are installed in accordance with the level. The distance should be less than the length of the rule by 15-20 cm. The choice of its length will depend on the number of people who carry out all the work, since one person is not able to cope with a tool whose length is more than 1 m. using a quick-setting adhesive on a gypsum base. The glue should be applied in the form of "lozenges", located every 25-30 cm along the slats. To achieve horizontality for each plane in which the slats should be located, you can use the level. If the glue on the gypsum base is already seized, then the cement and sand solution (1: 3) is poured onto the floor, filling the space on the plane between the beacons.  Determination of the flatness of the floor with the help of slats. Proceeding by the rule in the form of a zigzag on the established racks, pulling off the excess composition in the direction of the exit, and as a result, an even surface is obtained. Then the floor surface is left to dry for a long period. If necessary, then excess cement is knocked down with a chisel. All grooves can be filled with a cement-sand mixture. If you find satisfactory results of measurements of the horizontal plane of the floor, you should use not a conventional screed, but a special solution of polymer cement, that is, a self-leveling floor. Laying linoleum on the surface of the concrete floor requires pouring the solution in the required amount on the floor, and then the material is rolled using a toothed roller having a long handle. If necessary, it is necessary to wear special footwear, which is waterproof. Back to contents</a>

Determination of the flatness of the floor with the help of slats. Proceeding by the rule in the form of a zigzag on the established racks, pulling off the excess composition in the direction of the exit, and as a result, an even surface is obtained. Then the floor surface is left to dry for a long period. If necessary, then excess cement is knocked down with a chisel. All grooves can be filled with a cement-sand mixture. If you find satisfactory results of measurements of the horizontal plane of the floor, you should use not a conventional screed, but a special solution of polymer cement, that is, a self-leveling floor. Laying linoleum on the surface of the concrete floor requires pouring the solution in the required amount on the floor, and then the material is rolled using a toothed roller having a long handle. If necessary, it is necessary to wear special footwear, which is waterproof. Back to contents</a>

How to put linoleum on the floor of concrete with your own hands?

Back to contents</a> Features of choosing the right type of linoleumBefore laying the coating on the concrete surface of the floor, it is necessary to wait a while until it completely dry. Due to the low vapor permeability of the coating with a damp base, the linoleum decays. The floor before its packing is brought in full order, that is not only leveled, but also cleared of debris. For this purpose, you can use a dry brush or a vacuum cleaner. Laying linoleum on a concrete foundation by decking requires a very careful selection of material.  Linoleum classification table.It is imperative to use a multi-layer coating, the base of which is insulated with felt or foamed. It should be relatively thick. Choosing linoleum in a small room, it is better to buy a roll of such a size that the linoleum is laid in the full width of the material without joints. When cutting coverings, lighting must be taken into account. First, roll out the roll, which is then marked and cut so as to bend the material on each side. During the marking, it is imperative to take into account the coincidence of the pattern of individual parts of the linoleum, if it has to be laid in a non-integral piece. When the linoleum has already been cut, it is left to lie flat for two days. The material must be at the ambient temperature level. Further, each unevenness is smoothed out. If necessary, the material is cut. When using a marble-like or one-color type of linoleum, it must be laid in the direction of the light entering the room. The drawing should be at right angles to the outside walls. If you need to do with a picture, then parts of it are placed, observing the longitudinal direction of the room. Exterior walls should be parallel to the drawing. Back to the table of contents</a> How to properly glue the linoleum to the concrete floor?

Linoleum classification table.It is imperative to use a multi-layer coating, the base of which is insulated with felt or foamed. It should be relatively thick. Choosing linoleum in a small room, it is better to buy a roll of such a size that the linoleum is laid in the full width of the material without joints. When cutting coverings, lighting must be taken into account. First, roll out the roll, which is then marked and cut so as to bend the material on each side. During the marking, it is imperative to take into account the coincidence of the pattern of individual parts of the linoleum, if it has to be laid in a non-integral piece. When the linoleum has already been cut, it is left to lie flat for two days. The material must be at the ambient temperature level. Further, each unevenness is smoothed out. If necessary, the material is cut. When using a marble-like or one-color type of linoleum, it must be laid in the direction of the light entering the room. The drawing should be at right angles to the outside walls. If you need to do with a picture, then parts of it are placed, observing the longitudinal direction of the room. Exterior walls should be parallel to the drawing. Back to the table of contents</a> How to properly glue the linoleum to the concrete floor?  Scheme laying linoleum. If the surface of the concrete base meets the requirements, then the linoleum is laid directly on it. Pay attention to the fact that the temperature in the room does not fall below the level of 15 degrees, and the humidity level was not more than 5%. Materials and tools that will be needed in the process of gluing the coating to the concrete base are as follows:

Scheme laying linoleum. If the surface of the concrete base meets the requirements, then the linoleum is laid directly on it. Pay attention to the fact that the temperature in the room does not fall below the level of 15 degrees, and the humidity level was not more than 5%. Materials and tools that will be needed in the process of gluing the coating to the concrete base are as follows:

Applicable adhesive should have a goodadhesion to the concrete floor surface. Often used bitumen mastic, which has good properties of waterproofing. This type of adhesive makes it possible to condense moisture under the linoleum coating. Experts recommend the creation of a layer in the gap before laying the cover made of a fibreboard. To apply them apply bitumen mastic. If you want to lay a linoleum that is not insulated, then under the sheet coating you can lay the additional insulation, which is an extruded polystyrene foam. Trimming of the coating along the edges should be done so that the distance between the coating and the wall, which is not less than 10 mm, can remain. After installing the skirting, all gaps will not be visible. Otherwise, as a result of stretching uncircumed linoleum, it will rest against the walls, which will cause the material to swell. If the floor space is less than 20 m², the linoleum is not glued. It is more difficult to solve the problem of floor covering in large rooms, when laying the floor is done in a row of several strips. To do this, you should fold the canvas in half, then one half must be laid on the other. The glue is applied with a notched trowel. First, you should lubricate the floor and only one half of the material, then glue it to the floor surface. After this, you should do the same operation, greasing the second half with glue. When the material is glued, a roller is used to wrap it to the floor. Then the material should be left until completely adhered. After that, the plinth and the bar on the threshold of the room are installed.