on fiberboard requires careful preparationmaterial. Rolling out the roll along the entire perimeter of the room allows the linoleum to straighten out spontaneously: all folds and creases under room conditions (temperature, humidity) are leveled out. Single irregularities that have not disappeared are leveled out by installing a press. Structure of household linoleum.If this measure does not give the desired result of leveling the material, then it makes sense to return the roll to the seller. The readiness of the coating for laying is checked quite simply: its surface should become perfectly flat. If so, then it is possible to lay linoleum either on chipboard or on fiberboard.

Structure of household linoleum.If this measure does not give the desired result of leveling the material, then it makes sense to return the roll to the seller. The readiness of the coating for laying is checked quite simply: its surface should become perfectly flat. If so, then it is possible to lay linoleum either on chipboard or on fiberboard.

Laying linoleum on chipboard: three ways

Sequence of laying fiberboard sheets on the floor.

Sequence of laying fiberboard sheets on the floor.

Return to Contents</a>

Manufacture of flooring from particleboard

Technical characteristics of chipboard.Chipboards are usually used to level out the unevenness of a wooden floor when laying linoleum. Fiberboards are strongly affected by moisture. The slightest moisture on the boards can cause them to deform after six months. To avoid this problem, it is important to install high-quality waterproofing, which involves:

Technical characteristics of chipboard.Chipboards are usually used to level out the unevenness of a wooden floor when laying linoleum. Fiberboards are strongly affected by moisture. The slightest moisture on the boards can cause them to deform after six months. To avoid this problem, it is important to install high-quality waterproofing, which involves:

- drying of the floor surface at any stage of the work;

- laying under a layer of fiberboard polyethylene film with an overlap between sheets of 5-10 cm;

- processing of linseed slabs as far as possible.

After purchasing the slabs, they are cut and leftlie on the floor for 3-5 days. After which they are attached to the floor, taking into account that for a certain type of base there is a specific installation option:

Cutting linoleum.Nowadays, the method of fixing the slabs to the base with dowels is more common. Such a substrate is easier to dismantle later. But when it is installed, additional irregularities are created on top of the slabs, which will affect the final coating in the future. To avoid this, recesses are made in the fiberboard to such a size that the screw heads fit into them. The irregularities that arise after screwing are eliminated by puttying. Before laying chipboard and fiberboard, you need to finally make sure that this procedure cannot be avoided. After all, such a flooring is most often arranged by leveling a wooden floor or organizing logs. For leveling a concrete floor, there is now an excellent alternative - the use of self-leveling mixtures, and for making a substrate, it is more advisable to use a cork covering (or any other, but so that it is rigid). Return to the table of contents</a>

Cutting linoleum.Nowadays, the method of fixing the slabs to the base with dowels is more common. Such a substrate is easier to dismantle later. But when it is installed, additional irregularities are created on top of the slabs, which will affect the final coating in the future. To avoid this, recesses are made in the fiberboard to such a size that the screw heads fit into them. The irregularities that arise after screwing are eliminated by puttying. Before laying chipboard and fiberboard, you need to finally make sure that this procedure cannot be avoided. After all, such a flooring is most often arranged by leveling a wooden floor or organizing logs. For leveling a concrete floor, there is now an excellent alternative - the use of self-leveling mixtures, and for making a substrate, it is more advisable to use a cork covering (or any other, but so that it is rigid). Return to the table of contents</a>

Bonding linoleum to the base

Linoleum laying scheme.Unglued linoleum may stretch, ripple or gather under the legs of the sofa after some time. And all this will sooner or later lead to the covering tearing. Plus, the temperature difference when turning on the heating in the fall will affect the drying of the linoleum (the seams without glue will begin to move apart). To avoid these situations, it makes sense to glue the linoleum when laying. Then a reasonable question arises: what to glue linoleum with? In order for the linoleum to be glued thoroughly, you will need a special glue. Laying linoleum will be quite within the power of a home craftsman, if the tools and materials are chosen correctly. Gluing linoleum involves the use of a category of adhesives specially developed by professionals, which are best chosen. The main components of such adhesives are included in the composition by calculation so that their combination provides the best degree of adhesion to the surfaces of the materials being glued. They take into account the coefficients of shear elasticity, as well as modifiers responsible for the efficiency of operational characteristics under the corresponding temperature conditions and their changes.

Linoleum laying scheme.Unglued linoleum may stretch, ripple or gather under the legs of the sofa after some time. And all this will sooner or later lead to the covering tearing. Plus, the temperature difference when turning on the heating in the fall will affect the drying of the linoleum (the seams without glue will begin to move apart). To avoid these situations, it makes sense to glue the linoleum when laying. Then a reasonable question arises: what to glue linoleum with? In order for the linoleum to be glued thoroughly, you will need a special glue. Laying linoleum will be quite within the power of a home craftsman, if the tools and materials are chosen correctly. Gluing linoleum involves the use of a category of adhesives specially developed by professionals, which are best chosen. The main components of such adhesives are included in the composition by calculation so that their combination provides the best degree of adhesion to the surfaces of the materials being glued. They take into account the coefficients of shear elasticity, as well as modifiers responsible for the efficiency of operational characteristics under the corresponding temperature conditions and their changes. Types of linoleum by operational characteristicscharacteristics. The range of adhesive compositions for linoleum is diverse. It includes water-dispersion compositions, solvent-based compositions, polyurethane single- and double-dispersion. Water-dispersion adhesives are more in demand than others. They are distinguished by environmental safety, odorlessness, simplicity and economy in use (they are applied only to the base). These compositions are not resistant to moisture, therefore, when frozen, they change their original qualities. It is possible to lay coverings with a fabric and felt base, made of foamed polyurethane on such compositions. The most popular are acrylate adhesives, gumilax, bustilate, various mastics (dispersion and bitumen) based on fabric for linoleum. Such compositions are distributed on the floor surface using a notched trowel in an even layer, after which the covering is immediately laid. Two-component polyurethane adhesives form a rigid, strong bond, are durable and waterproof. They are most often used when laying commercial types of flooring in offices and industrial premises. But it has its own undesirable qualities. For example, high price, unpleasant odor, explosion and fire hazard. Gluing material with this type of glue is called cold welding, which is divided into three types. And type - is used to make a thin seam over already glued material with a connected pattern. The glue is colorless, due to which the gluing place is completely invisible. Cold welding type C is used to repair thickened seams, type T is used exclusively for professional installation. Return to contents</a>The procedure for gluing linoleumThey start with the wall that is furthest from the doorway. The material laid out on the floor surface is folded back along its entire length by half and the adhesive or mastic composition is distributed on the base or sheet (according to the selected product) using a notched trowel. A 10-12 cm strip is left uncoated along the edge to align the sheets. Then the material is lowered, rolled with a roller and the remaining part of the sheet is glued. After this, they start gluing the other sheet. After gluing the sheets, the joints are aligned and glued. Above, we discussed the main points of how to lay linoleum over chipboard/fiberboard in different ways, and how to install a substrate under the main floor covering.

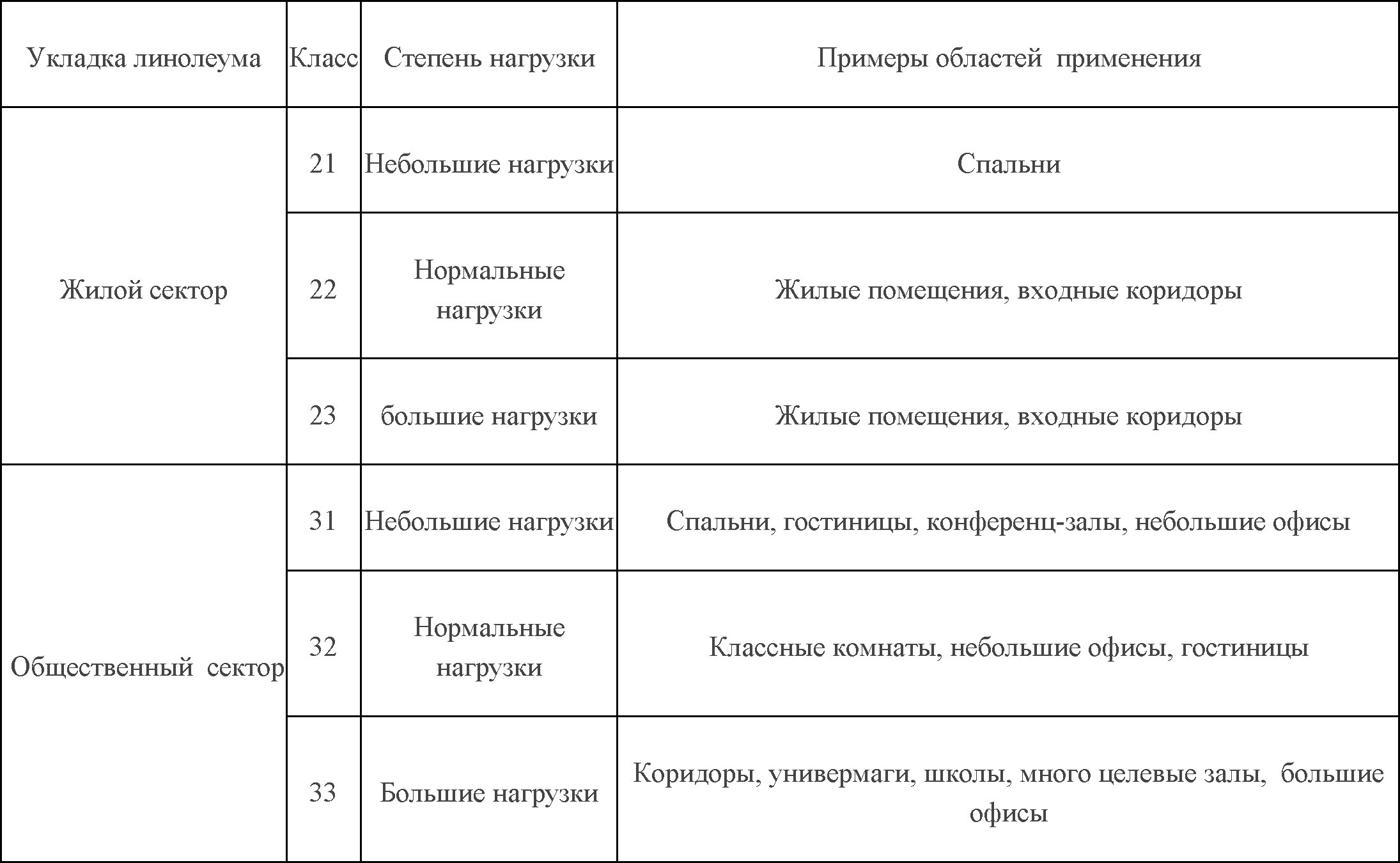

Types of linoleum by operational characteristicscharacteristics. The range of adhesive compositions for linoleum is diverse. It includes water-dispersion compositions, solvent-based compositions, polyurethane single- and double-dispersion. Water-dispersion adhesives are more in demand than others. They are distinguished by environmental safety, odorlessness, simplicity and economy in use (they are applied only to the base). These compositions are not resistant to moisture, therefore, when frozen, they change their original qualities. It is possible to lay coverings with a fabric and felt base, made of foamed polyurethane on such compositions. The most popular are acrylate adhesives, gumilax, bustilate, various mastics (dispersion and bitumen) based on fabric for linoleum. Such compositions are distributed on the floor surface using a notched trowel in an even layer, after which the covering is immediately laid. Two-component polyurethane adhesives form a rigid, strong bond, are durable and waterproof. They are most often used when laying commercial types of flooring in offices and industrial premises. But it has its own undesirable qualities. For example, high price, unpleasant odor, explosion and fire hazard. Gluing material with this type of glue is called cold welding, which is divided into three types. And type - is used to make a thin seam over already glued material with a connected pattern. The glue is colorless, due to which the gluing place is completely invisible. Cold welding type C is used to repair thickened seams, type T is used exclusively for professional installation. Return to contents</a>The procedure for gluing linoleumThey start with the wall that is furthest from the doorway. The material laid out on the floor surface is folded back along its entire length by half and the adhesive or mastic composition is distributed on the base or sheet (according to the selected product) using a notched trowel. A 10-12 cm strip is left uncoated along the edge to align the sheets. Then the material is lowered, rolled with a roller and the remaining part of the sheet is glued. After this, they start gluing the other sheet. After gluing the sheets, the joints are aligned and glued. Above, we discussed the main points of how to lay linoleum over chipboard/fiberboard in different ways, and how to install a substrate under the main floor covering.