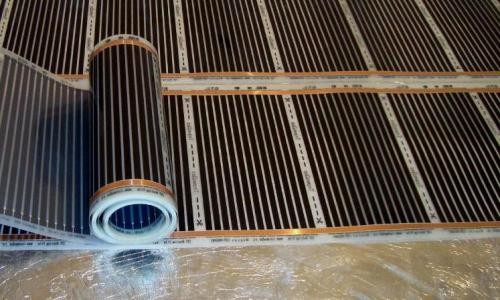

This type of flooring, or rather material,which heats the main floor, is quite new on the market. It is a thin, organic film. It includes carbon polymer, carbon elements, which act as a heating element and emit infrared waves, safe for the environment and human health. Do-it-yourself installation of a film warm floor is easy. The film floor has different modes, so itis suitable for laying under any coverings. Film heated floor is surprisingly efficient in heating, considering its simplicity, ease of installation and dimensions. The efficiency is 15% higher than other heating methods. Such a floor is both economical and completely environmentally friendly. Advantages:

The film floor has different modes, so itis suitable for laying under any coverings. Film heated floor is surprisingly efficient in heating, considering its simplicity, ease of installation and dimensions. The efficiency is 15% higher than other heating methods. Such a floor is both economical and completely environmentally friendly. Advantages:

Experts note that the best method of laying a warm floor is "dry" installation. The heating parts are placed under the main covering without various ties or glue.

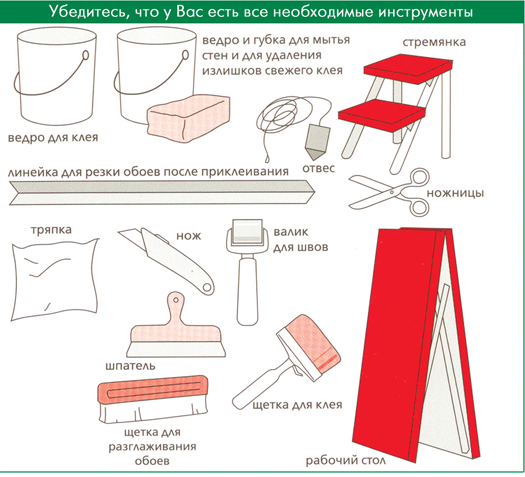

Tools and materials used in work

Tools for laying film floors.

Tools for laying film floors.

- heating element, lining of thermal insulation;

- wires and work regulator;

- film floor;

- tape, tape;

- a box for the distribution of wiring;

- screwdrivers, pliers, nippers, knives, scissors;

- devices for working with electrical wires: strippers, condenser tubes for connecting wires and the like;

- protective means when working with electricity, rubber gloves.

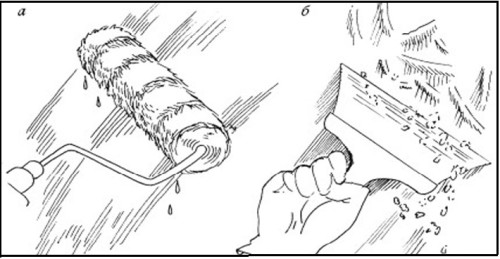

First, check the surface of the subfloorabsence of significant irregularities. Acceptable irregularities are about 2 mm. If they are significant, then it is necessary to grind concrete or scrape a wooden floor. The film can be laid on any surface, the main condition is evenness and dryness. The subfloor should be free of small debris and dust. The heat-insulating underlay is laid. It is laid so that it is smooth and even without folds and wrinkles, with the metallized surface facing up. The latter consists of strips of material. They are placed "end to end" with each previous one, secured with ordinary tape. Return to contents</a>

Basic preparation for floor installation

Scheme of warm film floor.After the base is prepared, they begin installation. For effective heating of the room, if it is produced only with such material, it is necessary that its area be at least 70% of the total area of the room, in other cases - 40-50%. It is necessary to remember that there should be a gap of no more than 10 cm from the wall to the edge of the material. Before starting installation, read the attached instructions. This must be done without fail, since the connection and installation of floors of different types and manufacturers can be very different from each other. The warm floor is laid, using as little material as possible. To avoid a large number of connections and excessive consumption of wires, it will be possible to cut it in such a way that as few stripes as possible come out. That is, the cutting is done lengthwise. There are special marks on the film, according to which it is necessary to cut, which will exclude damage to the carbon inserts. Return to the table of contents</a>

Scheme of warm film floor.After the base is prepared, they begin installation. For effective heating of the room, if it is produced only with such material, it is necessary that its area be at least 70% of the total area of the room, in other cases - 40-50%. It is necessary to remember that there should be a gap of no more than 10 cm from the wall to the edge of the material. Before starting installation, read the attached instructions. This must be done without fail, since the connection and installation of floors of different types and manufacturers can be very different from each other. The warm floor is laid, using as little material as possible. To avoid a large number of connections and excessive consumption of wires, it will be possible to cut it in such a way that as few stripes as possible come out. That is, the cutting is done lengthwise. There are special marks on the film, according to which it is necessary to cut, which will exclude damage to the carbon inserts. Return to the table of contents</a>

Floor installation: recommendations

Standard installation diagram of film flooring.The sheets are fixed with tape between themselves and the subfloor; they must be stable and not move. The places for connecting the wires are brought out under the baseboard, as well as on the edges of the covering. The thermal film is fixed with tape in relation to the insulating gasket. This will eliminate shifts. They are fixed tightly, so that the heating will be uniform enough. Do not allow pieces to overlap one another. It is necessary to remove all kinds of creases, folds, overlaps, overlaps of parts of the material on top of each other. Copper buses are located at the bottom. The clamps for the contacts are connected to the copper buses. Two such clamps are designed for one strip, their number corresponds to the number of copper strips. It is necessary to ensure that the contacts are synchronously located in one direction to the wall on which the distribution box with the thermostat is located. Special clamps are included in the kit; they are fixed with small pliers on the wires. The wires are connected to the contacts of the clamps; each of them must be insulated. Then the distribution box is mounted. Here you need to take safety precautions when working with electricity. This work, however, is within the power of any person with minimal knowledge of such work. The necessary wires are connected to the box. During such work, you need to turn off the power to avoid electric shock. Wires from the heating structure are connected and connected to the box. In this case, the connection is made in a parallel circuit. In order to conveniently arrange the material and wires in the thermal insulation, shallow trenches are made. This will eliminate bulging, surface relief, and also protect the wires themselves from damage. Return to the table of contents</a>

Standard installation diagram of film flooring.The sheets are fixed with tape between themselves and the subfloor; they must be stable and not move. The places for connecting the wires are brought out under the baseboard, as well as on the edges of the covering. The thermal film is fixed with tape in relation to the insulating gasket. This will eliminate shifts. They are fixed tightly, so that the heating will be uniform enough. Do not allow pieces to overlap one another. It is necessary to remove all kinds of creases, folds, overlaps, overlaps of parts of the material on top of each other. Copper buses are located at the bottom. The clamps for the contacts are connected to the copper buses. Two such clamps are designed for one strip, their number corresponds to the number of copper strips. It is necessary to ensure that the contacts are synchronously located in one direction to the wall on which the distribution box with the thermostat is located. Special clamps are included in the kit; they are fixed with small pliers on the wires. The wires are connected to the contacts of the clamps; each of them must be insulated. Then the distribution box is mounted. Here you need to take safety precautions when working with electricity. This work, however, is within the power of any person with minimal knowledge of such work. The necessary wires are connected to the box. During such work, you need to turn off the power to avoid electric shock. Wires from the heating structure are connected and connected to the box. In this case, the connection is made in a parallel circuit. In order to conveniently arrange the material and wires in the thermal insulation, shallow trenches are made. This will eliminate bulging, surface relief, and also protect the wires themselves from damage. Return to the table of contents</a>

Sensor: some moments

Sequence of installation of the temperature sensor.An important element of a heated floor is a temperature sensor. It is placed in a place where it will be protected from damage. The sensor should be placed close enough to the heating structure, under the covering. Such a place is suitable where furniture is placed that rarely moves. A groove of its size is cut in the substrate for it. The sensor is fixed with bitumen insulation or electrical tape in the smallest load zones. A groove is cut in the thermal insulation for it. The length of its wires is up to 50 m, no more. If possible, it is recommended to install another temperature sensor that records overheating. In this case, the thermostat must support this function. It provides enhanced temperature control in unsafe areas of potential overheating. If overheating occurs, the floor will turn off. Return to contents</a>

Sequence of installation of the temperature sensor.An important element of a heated floor is a temperature sensor. It is placed in a place where it will be protected from damage. The sensor should be placed close enough to the heating structure, under the covering. Such a place is suitable where furniture is placed that rarely moves. A groove of its size is cut in the substrate for it. The sensor is fixed with bitumen insulation or electrical tape in the smallest load zones. A groove is cut in the thermal insulation for it. The length of its wires is up to 50 m, no more. If possible, it is recommended to install another temperature sensor that records overheating. In this case, the thermostat must support this function. It provides enhanced temperature control in unsafe areas of potential overheating. If overheating occurs, the floor will turn off. Return to contents</a>

Installing the thermostat

Wiring diagram for film thermostatunderfloor heating. First, you need to make sure that the system is safe and isolated. Each time, it is necessary to lay it with a non-conductive material from the bottom and top and insulate it with electrical tape. The underfloor heating is installed, connected to the network, then it is connected to the control and regulation system. The place for thermostats and distribution boxes is chosen at a distance of 15-20 cm from the floor surface. It is taken into account that this element is installed strictly according to the attached instructions. The total power of the film area must be the one for which it is designed. The system is connected using a residual current device, the rated voltage for operation is no more than 30 mA. Such underfloor heating does not necessarily need to be connected to the ground loop. Return to contents</a>

Wiring diagram for film thermostatunderfloor heating. First, you need to make sure that the system is safe and isolated. Each time, it is necessary to lay it with a non-conductive material from the bottom and top and insulate it with electrical tape. The underfloor heating is installed, connected to the network, then it is connected to the control and regulation system. The place for thermostats and distribution boxes is chosen at a distance of 15-20 cm from the floor surface. It is taken into account that this element is installed strictly according to the attached instructions. The total power of the film area must be the one for which it is designed. The system is connected using a residual current device, the rated voltage for operation is no more than 30 mA. Such underfloor heating does not necessarily need to be connected to the ground loop. Return to contents</a>

Some precautions

Laying film flooring under laminate.Despite its sufficient strength for its thickness, the film is still susceptible to mechanical damage, so it must be protected. If a hard material, such as laminate, is used as the main material, then a simple thick polyethylene film will be enough for protection. It is laid on top of the film floor. When using carpet, linoleum and similar soft materials, it is recommended to protect the warm film floor more thoroughly and reliably. Then plywood or wood board is added to the polyethylene film. They can be both very thin and quite thick. When laying them, it is necessary to carefully ensure that they do not damage the film. If it is decided to use tiles as the main floor, then, together with laying the film floor, this process will become more labor-intensive. Polyethylene is placed on top of the film, and then a reinforced mesh for construction or painting work is laid. It is important that it does not conduct electricity. It is fixed in such a way as not to damage the heating elements, copper busbars, wiring. Then the tiles are laid on special tile adhesive. The process is quite simple, the complexity lies in the fact that you need to be quite careful: the film floor should be without folds, smooth. Moments that should be paid attention to:

Laying film flooring under laminate.Despite its sufficient strength for its thickness, the film is still susceptible to mechanical damage, so it must be protected. If a hard material, such as laminate, is used as the main material, then a simple thick polyethylene film will be enough for protection. It is laid on top of the film floor. When using carpet, linoleum and similar soft materials, it is recommended to protect the warm film floor more thoroughly and reliably. Then plywood or wood board is added to the polyethylene film. They can be both very thin and quite thick. When laying them, it is necessary to carefully ensure that they do not damage the film. If it is decided to use tiles as the main floor, then, together with laying the film floor, this process will become more labor-intensive. Polyethylene is placed on top of the film, and then a reinforced mesh for construction or painting work is laid. It is important that it does not conduct electricity. It is fixed in such a way as not to damage the heating elements, copper busbars, wiring. Then the tiles are laid on special tile adhesive. The process is quite simple, the complexity lies in the fact that you need to be quite careful: the film floor should be without folds, smooth. Moments that should be paid attention to:

- Do not mount at high humidity and below zero temperatures;

- It is forbidden to bend it with an acute angle over a section of more than 5 cm;

- nails for fixation and the like do not apply;

- It is forbidden to overlap strips, make holes in them;

- Do not use more than 10 meters of linear per piece and use this with a consumption of more than 10 A;

- It is forbidden to mount near fireplaces and heating appliances;

- It is impossible to include film in a roll, use a substrate with metal elements.

And finally, remember that in case of flooding, you need to turn off the underlay and dry it naturally. The main thing is not to use the floor to dry wet items. Good luck!