During the execution of repair works, the most difficult and responsible process is, especially their corners. Tools for plastering walls. However, there are certain differences in how to plaster the corners of walls.

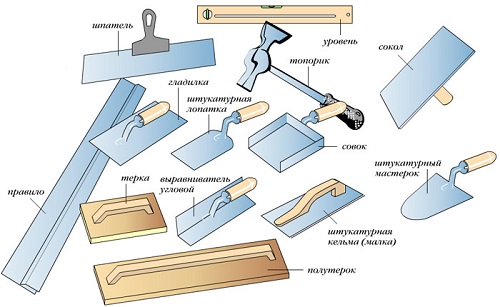

Tools for plastering walls. However, there are certain differences in how to plaster the corners of walls.

Plaster of internal corners: necessary tools and materials

In order to organize, you need to prepare the following materials and tools:

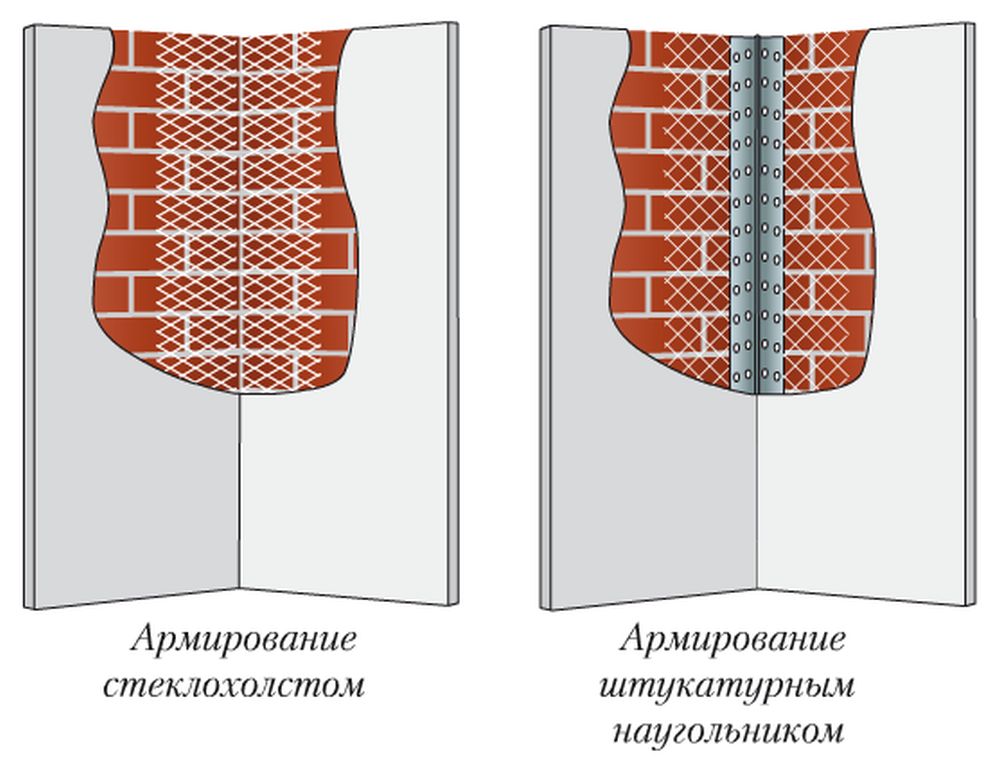

Scheme of options for plastering internal corners.There are 2 options for finishing internal corners using plaster. The first option involves plastering corners on two adjacent surfaces. The second option involves joining the plastered surface with the untreated one. But the basic principle of the work will be approximately the same. First, you need to apply primer to the wall to be treated, and you need to do this moving towards the untreated plane. After that, the primer needs to be rubbed down with a rule. Then you need to form a corner and scratch the material on its surface with a special float, on which there will be nails. Such plastering of walls is done with a trowel, which needs to be applied with its edge at an angle of 30 degrees to the base of the wall and brought to the corner. After it enters the material, you need to start slowly moving it along the surface from top to bottom. After that, the trowel needs to be applied with its edge to the hard part of the surface, but flat, on the newly applied and slightly dried plaster. In this way, you can create a corner on 2 sides. Then you need to wait until the plaster dries. Then it will be necessary to apply a water-repellent primer to its surface, which is also recommended to be smoothed in the direction of the untreated surface. Return to the table of contents</a>

Scheme of options for plastering internal corners.There are 2 options for finishing internal corners using plaster. The first option involves plastering corners on two adjacent surfaces. The second option involves joining the plastered surface with the untreated one. But the basic principle of the work will be approximately the same. First, you need to apply primer to the wall to be treated, and you need to do this moving towards the untreated plane. After that, the primer needs to be rubbed down with a rule. Then you need to form a corner and scratch the material on its surface with a special float, on which there will be nails. Such plastering of walls is done with a trowel, which needs to be applied with its edge at an angle of 30 degrees to the base of the wall and brought to the corner. After it enters the material, you need to start slowly moving it along the surface from top to bottom. After that, the trowel needs to be applied with its edge to the hard part of the surface, but flat, on the newly applied and slightly dried plaster. In this way, you can create a corner on 2 sides. Then you need to wait until the plaster dries. Then it will be necessary to apply a water-repellent primer to its surface, which is also recommended to be smoothed in the direction of the untreated surface. Return to the table of contents</a>

External joint processing

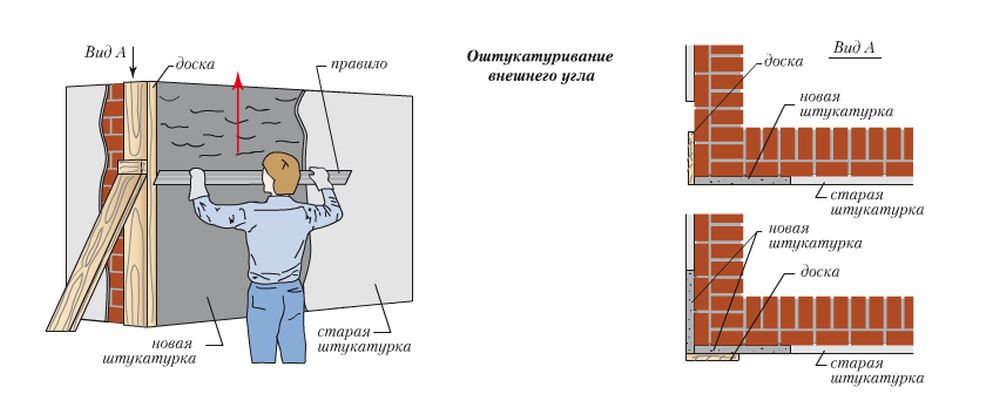

Scheme of plastering external corners.The outer corners of the walls can also be processed in 2 ways. To perform the first method, you need to use a metal profile. This version of plastering corners will allow you to process two adjacent surfaces at once. In this case, the corners will be even, smooth and very neat. When using the second method, you need to use a beacon strip. With its help, the sides of the corners are plastered in turn. In this case, it is also recommended to use metal corners (namely, a metal corner strip), which will help to perform the plastering. Using a strip will help to get a fairly strong corner. In order to correctly understand how to plaster the corners of walls using a corner profile, you need to remember that you first need to install the profile, and then apply the finishing material to its surface. Special shelves made in the form of a grid are attached to the central part of such a profile. This design allows you to hold the plaster on the surface of the profile during its application. The length of the profile is adjustable: too long a length can be reduced using metal scissors. If the profile needs to be trimmed along the corner joint, this can be done using a hacksaw for metal. Return to the table of contents</a>

Scheme of plastering external corners.The outer corners of the walls can also be processed in 2 ways. To perform the first method, you need to use a metal profile. This version of plastering corners will allow you to process two adjacent surfaces at once. In this case, the corners will be even, smooth and very neat. When using the second method, you need to use a beacon strip. With its help, the sides of the corners are plastered in turn. In this case, it is also recommended to use metal corners (namely, a metal corner strip), which will help to perform the plastering. Using a strip will help to get a fairly strong corner. In order to correctly understand how to plaster the corners of walls using a corner profile, you need to remember that you first need to install the profile, and then apply the finishing material to its surface. Special shelves made in the form of a grid are attached to the central part of such a profile. This design allows you to hold the plaster on the surface of the profile during its application. The length of the profile is adjustable: too long a length can be reduced using metal scissors. If the profile needs to be trimmed along the corner joint, this can be done using a hacksaw for metal. Return to the table of contents</a>

Errors during installation

Plastering of walls and corners should be carried outcarefully, so that the plaster layer is the same everywhere. In the process of forming the surface, many craftsmen make a number of basic mistakes. These mistakes can be avoided if you know the general principles of work. The most common mistake is to carry out work without accurately assessing the condition of the walls. Such carelessness can lead to cracks in the coating, which will lead to its further crumbling. To avoid this, you need to carefully prepare the wall surface. The next mistake is that different layers of finishing material are applied with different thicknesses. As a result, the drying of the material is uneven. Therefore, you should wait a significant time until it dries completely. Another common mistake is applying the material to the wall without pre-treating it with a primer. This can lead to the fact that after the solution dries, the contours of the seams between the blocks and bricks will be visible through it. Moreover, in corner joints, in places of their contact with window structures and door frames, it is necessary to make expansion joints. To achieve this, first you need to do finishing work, attach expansion slats to the surface being processed. They will help to avoid cracks. If galvanized corner profiles are used, they cannot be cut with a grinder. Otherwise, the protective zinc layer will be destroyed. Such a profile must be used when forming an angle in places with very high traffic. If you approach the formation of corners on the walls correctly, and perform the work carefully and responsibly, then the construction of corners made of plaster will serve for a long time and reliably.

Plastering of walls and corners should be carried outcarefully, so that the plaster layer is the same everywhere. In the process of forming the surface, many craftsmen make a number of basic mistakes. These mistakes can be avoided if you know the general principles of work. The most common mistake is to carry out work without accurately assessing the condition of the walls. Such carelessness can lead to cracks in the coating, which will lead to its further crumbling. To avoid this, you need to carefully prepare the wall surface. The next mistake is that different layers of finishing material are applied with different thicknesses. As a result, the drying of the material is uneven. Therefore, you should wait a significant time until it dries completely. Another common mistake is applying the material to the wall without pre-treating it with a primer. This can lead to the fact that after the solution dries, the contours of the seams between the blocks and bricks will be visible through it. Moreover, in corner joints, in places of their contact with window structures and door frames, it is necessary to make expansion joints. To achieve this, first you need to do finishing work, attach expansion slats to the surface being processed. They will help to avoid cracks. If galvanized corner profiles are used, they cannot be cut with a grinder. Otherwise, the protective zinc layer will be destroyed. Such a profile must be used when forming an angle in places with very high traffic. If you approach the formation of corners on the walls correctly, and perform the work carefully and responsibly, then the construction of corners made of plaster will serve for a long time and reliably.